Ketones

Composite brackets for life-of-aircraft service

Reinforced PEEK molding formulated for jet fuel/hydraulic fluid immersion.

Read MoreOvermolding expands PEEK’s range in composites

A new polymer and a hybrid process enable production of complex, high-load-capable, fiber-reinforced brackets and clips in minutes.

Read MoreThermosets vs. thermoplastics: Is the battle over?

Dale Brosius, the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (IACMI) and a regular CW columnist, sees a shift in the industry from infighting between proponents of thermoset and thermoplastic composites to a healthier competitive atmosphere that serves to make composites overall more competitive with legacy materials.

Read MoreThermoplastic composites technology: A view from Europe

For this Dutch consortium, bringing the manufacturability of thermoplastic materials to maturity is the goal in concert with OEMs, materials and equipment supplier members.

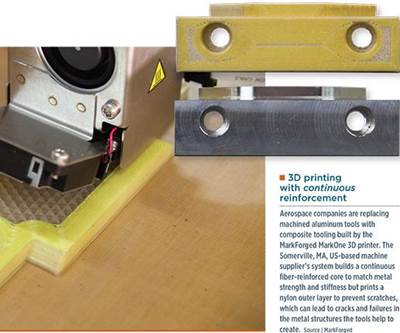

Read More3D Printing: Niche or next step to manufacturing on demand?

With and without fiber reinforcement, additive manufacturing is making an impact, but to what end?

Read MoreThermoplastic composites “clip” time, labor on small but crucial parts

Preconsolidated carbon fiber/PPS and PEEK and automated thermoforming enable six-figure production of connectors for the Airbus A350 XWB.

Read MoreAdditive manufacturing: Can you print a car?

Collaborative demonstration dispels doubt about 3D printing’s disruptive potential for direct-to-digital manufacturing of just about anything BIG.

Read MoreNew hydraulic press for automated processing of thermoplastic CFRP

Wickert Presstech delivers new system to German Aerospace Center which reportedly can process all materials and uses latest in automated technology.

Read MoreTooling (2015)

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

Read MoreFiber reinforcement forms

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

Read More