Thermosets vs. thermoplastics: Is the battle over?

Dale Brosius, the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (IACMI) and a regular CW columnist, sees a shift in the industry from infighting between proponents of thermoset and thermoplastic composites to a healthier competitive atmosphere that serves to make composites overall more competitive with legacy materials.

Shortly after I moved from Dow Chemical Co. to Fiberite (now part of Cytec Industries) in 1987, I attended a sales meeting where a colleague from Fiberite’s parent company, Imperial Chemical Industries (ICI), avowed that, within a decade, thermoplastic composite prepregs would displace thermoset prepregs throughout the aerospace industry. ICI had developed carbon fiber prepregs based on high-temperature PEEK thermoplastic, and the advocate cited advantages, including infinite shelf life, lack of lengthy cure times, easier recyclability and high impact strength. Almost 30 years later, his prediction is unfulfilled: Thermoplastics have made some inroads, on leading edges of some Airbus planes and in various beams, fuselage clips and other structures. And most modern thermoset prepreg systems incorporate thermoplastic polymers at some level to improve damage tolerance. But more than 95% of aerospace prepregs are still thermoset.

Full disclosure: I have spent most of my career either promoting or working with thermoset materials. They have attributes that make them attractive for highly stressed parts, including lower processing viscosities for RTM, infusion or prepreg manufacture (which permit high fiber volumes), superior adhesion to fibers (especially true of epoxies), paint and non-composite materials, and high thermal resistance, especially to compressive creep. This enables polyimides to survive the high-temperature zones in jet engines, and phenolic compounds to resist the compressive forces placed on molded brake pistons on a long downhill descent. Composites for wind turbine blades are almost exclusively thermoset, as are the major structures in the Boeing 787 and Airbus A350. To date, carbon fiber-intensive automotive structures, from Italian supercars to the BMW i3, feature thermoset matrices. Decades back, the knock on thermosets was that they cured too slowly, but I have seen electrical circuit breakers produced from polyester BMC in multi-cavity injection molds in cycle times of less than 15 seconds. A number of suppliers now offer resins for RTM with the potential for less than 90-second cure.

On the downside, many thermosets have limited shelf lives and there is the risk of spoilage. Whether or not fabricators recognize it, every thermoset mold is a chemical reactor — each part cycle is a polymerization that has to be carefully controlled to avoid exotherm and to achieve the desired state of cure. And if it goes wrong, you cannot grind it up and remold it — at least not easily.

That said, a fair portion of my time was spent competing against thermoplastics for certain applications, especially in the industrial sector, so I became very familiar with thermoplastics and how they are processed. For many years, thermoplastics have enjoyed a reputation as being “easy to process” — pourable, easy to automate, able to melt, solidify and remelt — with properties essentially defined by the material supplier, who had full control of the chemistry. Such materials were recyclable, as long as they were unreinforced or contained only short fibers or mineral fillers. The development of glass mat thermoplastics, which can be compression molded like SMC, and long fiber (typically 6 to 25 mm) pellets, which can be compression or injection molded, opened up new applications, especially in auto components. More recent introductions of continuous unidirectional and fabric-based thermoplastic materials, including carbon fiber versions, based on more economical and easier-to-process resins than PEEK, have positioned thermoplastics squarely against thermoset prepregs.

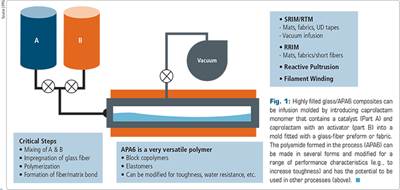

Recently, I have embraced a more neutral stance, having found numerous applications where thermoplastics might make more sense than thermosets, especially in composite structures. Having a broader palette is very exciting. Two emerging technologies for thermoplastics seem especially appealing. One, structural injection overmolding, uses a continuous-fiber structural “backbone,” either a flat sheet or a formed/consolidated insert, which is preheated and placed into a mold, behind which reinforced discontinuous materials are injected to form ribs, attachment points and other features (see CW’s recent coverage of an example of this strategy by clicking on "Overmolding expands PEEK’s range in composites," under "Editor's Picks," at top right). The second is thermoplastic RTM, where the native high viscosity of thermoplastic resins is circumvented by injecting low-viscosity monomers into a heated mold containing a fiber preform (similar to thermoset RTM). This is followed by what some call in-situ polymerization, resulting in a conventional thermoplastic polymer composite. So far, caprolactam (which forms polyamides) and acrylics show great promise using this technique. (Read more by clikcing on "Infusible thermoplastics via in-situ polymerization" under "Editor's Picks").

For decades, thermosets and thermoplastics competed partly by pointing out each other’s weaknesses. I don’t see as much of that today. Instead, I see healthy competition to develop material systems and processes that make composites overall more competitive with legacy materials, providing added value and new avenues to high performance. This is the right battlefront, and the one on which our industry — united — needs to prevail.

Related Content

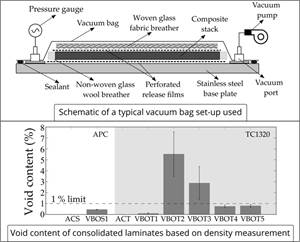

TPRC research studies void removal mechanisms in VBO processing

New publication evaluates vacuum bag only-consolidated carbon fiber/PEEK tapes to determine the role of different void removal mechanisms in thermoplastic composites.

Read MoreQueen’s University Belfast presents research in thermoplastic drilling performance optimization

Researchers have published findings from a multi-objective optimization study on carbon fiber-reinforced PEKK drilling in an effort to better understand the material for use in aviation fastenings.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreEaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

Read MoreRead Next

Infusible thermoplastics via in-situ polymerization

A low-viscosity monomer that can be polymerized in the mold enables infusion of continuous glass fiber with polyamide 6.

Read MoreOvermolding expands PEEK’s range in composites

A new polymer and a hybrid process enable production of complex, high-load-capable, fiber-reinforced brackets and clips in minutes.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More