Thermoplastic composites “clip” time, labor on small but crucial parts

Preconsolidated carbon fiber/PPS and PEEK and automated thermoforming enable six-figure production of connectors for the Airbus A350 XWB.

The reality for aircraft OEMs today is that each new generation of commercial aircraft delivered to airline and cargo customers must be lighter and more efficient than the planes that preceded them. The demand for greater efficiency led to the adoption of a composite airframes for the 787 Dreamliner, in The Boeing Co.’s (Chicago, IL, US) case, and the A350 XWB at Airbus (Hamburg, Germany and Toulouse, France). Given the successful launches of both aircraft, each manufacturer now faces a huge backlog of orders — and the heat is on all the suppliers in each OEM’s value chain to develop efficient, automated composites production to keep up with accelerating build rates.

Boeing opted for one-piece fuselage barrels for the 787, but Airbus enclosed each of the A350’s five major fuselage sections with four large shells or panels: two side panels, and an upper and a lower panel. Each panel is supported by a system of internal frames and stringers. The stringers are bonded directly to the skin panels, but an array of parts, called “clips,” attach the frames to the skin.

“We are responsible for the design and manufacture of more than 3,000 clips for different parts of the aircraft,” declares Dr. Angelos Miaris, responsible for operational part testing at Premium Aerotec (Bremen, Germany). As an Airbus subsidiary and part supplier, Premium Aerotec realized early on that its share of the huge clip part count on the aircraft would require a very short manufacturing cycle time, low labor demand and a great deal of flexibility. For these reasons, he says, thermoplastic matrix composites were the obvious material choice, paired with an automated thermoforming process.

“We started thermoplastic composites part manufacturing in 2005 in Bremen [Germany],” says Dr. Klaus Edelmann, responsible for thermoplastic technology at the company. “In 2007, we made 50 parts. Last year we produced more than 150,000 parts.” Indeed, Premium Aerotec Bremen is a major risk-sharing Tier 1 supplier partner in the A350 program, and is a “center of competence” for thermoplastics manufacturing. On the A350 program, the company is responsible for work packages that include fuselage section 13/14 (side, upper and lower shells, floor grid and assembly), and fuselage sections 16-18 (side shells, floor grid and pressure bulkhead), including all necessary clips involved in assembly. The clips have undergone an extensive testing campaign to ensure they meet Airbus requirements, and are already flying on the first A350 XWBs delivered to customers.

Clips and more clips

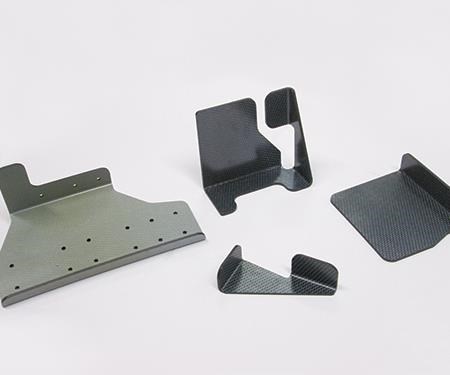

According to Miaris, the clips can be divided into four general categories: L-shaped, cleat, auto-stabilized and special (for examples, see Step 1, this page). Dimensions for clip types range from approximately 100 mm up to 800 mm in length (special clips are among the longest), and from 30 mm up to approximately 400 mm in width. As the smallest parts, cleats are considered stabilizing elements — they are mounted on other clips to provide locally higher stiffness at certain attachment locations, he explains.

To meet performance requirements, Premium Aerotec’s design engineers specified intermediate-modulus carbon fiber in either a polyphenylene sulfide (PPS) or polyetheretherketone (PEEK) resin matrix. The selected materials were PPS-CETEX semi-finished, pre-consolidated thermoplastic panels manufactured by TenCate Advanced Composites BV (Nijverdal, The Netherlands), reinforced with woven carbon fiber fabrics made with T300 carbon from Toray Industries (Tokyo, Japan). The carbon fiber/PEEK material used is a pre-consolidated Tenax TPCL laminate, also based on woven fabrics and manufactured by Toho Tenax Europe GmbH (Wuppertal, Germany). The panels have a quasi-isotropic layup and are supplied in different thicknesses, ranging from 1 mm to 5 mm, or 5 to 14 fabric plies, depending on attachment location and fuselage load conditions in that area. “The clips’ designs were optimized for the lightest possible weight,” Miaris explains. “We are using different material thicknesses for different load cases within the fuselage, to try to minimize weight.”

Edelmann adds that the higher-strength Tenax carbon fiber/PEEK was specified for clips in fuselage regions where higher loads will be experienced, generally around openings, such as cargo doors and passenger doors.

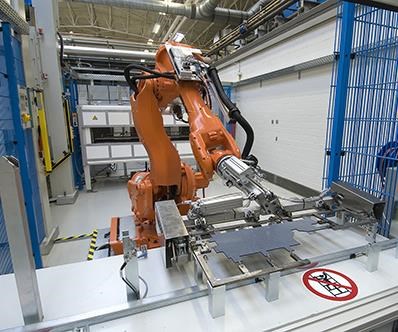

Premium Aerotec designed and developed an automated thermoforming production cell to meet the production demands. The cell incorporates two robots — one a “master” and the second a “slave” — driven by a sophisticated, proprietary computer process control system that, Miaris explains, is able to calculate workflow and rate based on forecasted OEM assembly demands, for just-in-time part delivery.

“The cell has a high degree of automation,” he says. “We’ve kept in mind the principles of high-rate manufacturing to make the work flow smooth, fast and paperless.”

To meet Airbus’ increasing production, which will be 13 shipsets per month by 2017, two more cells of the same design have been added at Bremen within the past six months, he adds.

Each work cell comprises six steps or functions:

- Cutting of thermoplastic panels into blanks on a high-speed automated cutting table

- Robotic transfer of the blanks to one of two infrared ovens for polymer melting (because PEEK and PPS require different melting temperatures)

- Robotic transfer of the heated blanks from infrared ovens to the thermoforming tool in the press

- Forming in the thermoforming press

- Robotic transfer of formed clips to the trimming station for edge trimming (and drilling of holes in some cases)

- Ultrasonic inspection and part number marking

The master, six-axis robot works four positions approximately every 20 seconds: moving a blank from the cutting table to the oven, taking a heated blank from the oven, moving the heated blank to the press and removing formed clips from the press to the trimming station. The slave robot’s role is to quickly change and position the correct forming tools in the press, depending on the type of clip needed. Miaris says that the cell produces clip parts on a “work order” or lot basis, with different clips produced for each order: “We may need 150 of one clip style, and only two of another, for a particular lot.”

Edelmann points out that two ovens are used for a shorter cycle time, since the melting process is the most time-consuming task in the system. Thus, two parts are always in the oven as a third is moved to the press.

Blank-cutting occurs on a high-speed, automated flatbed cutting table. A robust milling tool cuts the pre-consolidated panels, and the automated cutting system’s software nests the blank shapes for maximum efficiency and minimal waste. The scrapped nesting “skeletons,” or leftover cutting waste, are collected for recycling (described below).

As the robot moves a blank from the cutting table to an oven, it immediately transfers an already heated blank from the second oven to the press tool: “The two-oven design allows for different temperatures and helps maintain cycle speed, if material type changes,” explains Edelmann.

Meanwhile, the slave robot ensures that the correct forming tools are placed in the 125-MT thermoforming press ahead of the heated blanks. Forming tools are made of tooling steel or aluminum, depending on the part, and are designed in-house for each clip style by Premium Aerotec, but fabricated out-of-house by a tooling supplier. Edelmann adds that the tool-change operation is critical, given the large number of clip designs and sizes.

The master robot removes formed clips from the press and transfers them to the trimming station. Miaris explains that heating and forming of multi-ply thermoplastic material causes the plies to slide relative to each other, in-plane, similar to what happens if you bend a bound book. This “book effect” and the resulting sharp, stepped part edge is unacceptable, he explains, because it causes dimensional inaccuracy and can interfere with proper assembly. The edges are trimmed, therefore, with a milling tool at the trim station to achieve a clean edge that is perpendicular to the reinforcing plies, for final contour.

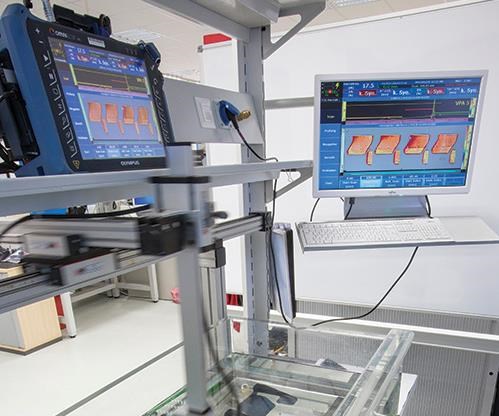

The final step is inspection of all parts, using phased-array, pulse-echo ultrasonic equipment from a European supplier. The semi-automated testing involves immersing parts in a tank for C-scan testing, but Miaris says that a few, more complex clips with joggles are manually inspected, using hand-held A-scan transducers. Tested parts are marked with an identifying radio frequency identification (RFID) tag to enable paperless tracking throughout the fuselage assembly process. Edelman reports that parts cycle through the stations in a mere 85 seconds.

Continuous improvement

Although the three existing cells continue serial clip production, Premium Aerotec has already determined where improvements can be made. The company is in the process of validating and qualifying new technologies: “We have a good process in place but, nevertheless, that doesn’t mean that all of the properties of the thermoplastic matrix are currently being used to the maximum,” asserts Miaris. Clips could be lighter, thinner and made still faster.

The company has built a prototype demonstrator workcell to investigate local heating and forming of clips — that is, instead of heating the entire blank prior to thermoforming, a portion of the blank is heated only where the shape change is needed. “Heating the entire blank and forming it works well for small, complicated parts, but it is very inefficient for production of larger, plain parts with just locally formed features, such as the L-shaped clips,” explains Miaris.

Local forming requires a infrared oven specially designed to heat only the specified region of the blank; robotic handling of the partially softened blanks; and a forming tool and press with positioning features that can locate the heated region correctly for forming. The concept has been extensively trialed, and parts have been tested using carbon fiber/PEEK and carbon fiber/PPS blanks. Adds Miaris: “Mechanical tests of locally formed parts have shown that mechanical properties fulfill the design requirements. And, differential scanning calorimetry [DSC] tests prove that resin crystallinity in the heated and formed region does not deviate from the crystallinity observed in the rest of the part.” Additional qualification with Airbus is underway.

In some cases, clips need to have a titanium shim attached, for additional fastener strength. Edelmann explains that at present, the titanium pieces are manually bonded to the clips using an adhesive, which slows the overall production process.

“We want to reduce the labor demand and develop a more cost-effective welding technology,” says Miaris. Two methods are under investigation: ultrasonic welding and induction welding. Tests have shown that the faster ultrasonic welding process holds the two materials together with strength adequate to endure handling, drilling and assembly on the shop floor, without damage to either material. Here, too, qualification of the process is pending.

Lastly, Premium Aerotec is investigating alternative reinforcement forms, specifically, unidirectional tapes, to replace woven carbon/thermoplastic panels. The company is working with research partner Fraunhofer ICT (Pfinztal, Germany) to design an automated method to produce custom layups for specific clips. “This would allow us to optimize, in an unrestricted way, the stacking sequence and ply orientation, for maximum design flexibility,” explains Miaris. Fraunhofer is developing a thermoplastic uni tape preforming sequence that employs Dieffenbacher’s (Eppingen, Germany) Relay automated moving-table layup technology, originally developed by now-defunct Fiberforge, to create a flat preform (for more on the Relay system, see “Dieffenbacher acquires ...." and "Tailored carbon fiber ...." under "Editor's Picks,” at top right). The preform blank then could be stamp-formed in a thermoforming cell. According to Miaris and Edelmann, tests on stamped uni tape demonstrator parts of high complexity have shown that they far surpass the performance possible using the woven carbon fiber-reinforced, semi-finished panel stock, with larger fiber volume fraction (60%, up from 55%) and less than 0.1% void content.

Sustainable production

Thermoplastic composites also bring to aircraft construction the additional promise of recyclability. Premium Aerotec is testing ways to reuse the scrap generated by the blank-cutting process in a long-fiber thermoplastic molding process. In one test, scrap is chopped and then hammer-milled, with the resulting chips processed with neat PPS in an extruder. The resulting compound was pressed into a clip shape and tested. Flexural strength of the molded clip showed that it retained 85% of the strength of the original carbon/PPS sheet material. Although no details on reuse have been revealed, Premum Aerotec indicates that the promising mechanical test results likely will lead to development of a secondary process.

“The challenge is to further expand the use of thermoplastics in the aerospace industry,” concludes Miaris. “In order to achieve that goal, new technologies are needed.” Thermoplastic composite parts certainly present attractive options in aircraft production, and Airbus has proven for several years — starting with thermoplastic wing structures on the A380 (see “Thermoplastic composites gain leading edge on the A380," under "Editor's Picks") — that it is willing to apply this material in many new and interesting ways. Ongoing innovation of the type envisioned by Premium Aerotec appears to promise an increased profile for thermoplastic composites for many years to come.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read More3D weaving capabilities achieve complex shapes, reduce weight and cost

JEC World 2024: Bally Ribbon Mills is displaying film-infused 3D woven joints, woven thermal protection systems (TPS) and woven composite 3D structures.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read More3D-woven composites find success in aerospace, space

CAMX 2024: Bally Ribbon Mills experts are displaying the company’s various joints, thermal protection system (TPS) technologies and other 3D woven composites for mission-critical applications.

Read MoreRead Next

Tailored carbon fiber blanks to move into steel stamping arena

Reduced scrap and cost driving forces behind new technique for automotive industry.

Read MoreThermoplastic composites gain leading edge on the A380

Breakthrough manufacturing process produces lightweight, affordable glass-reinforced PPS J-nose on the worlds largest commercial aircraft wing.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More