Materials

Composite wrap system combats corrosion in industrial tank repair

A fiberglass and carbon fiber composite wrap system enabled an Australian nickel mine to quickly repair a stainless steel ammonium sulphate feed tank and protect against future corrosion.

Read MoreToyoda Gosei develops seawater-derived fiber-reinforced material

Fiber reinforcement is formed from magnesium hydroxide derived from seawater, achieving plastic parts that contributed to improved environmental performance.

Read MoreBioStruct project to validate biocomposite-focused manufacturing processes

For the next 3 years, Ideko and European partners are working to develop and validate to TLR 7 novel processes to boost the use of natural fibers and biological resins.

Read MoreJCB Aero aircraft interior flooring panels incorporate SHD composites

High-performance carbon fiber prepreg using SHD’s FRVC411 epoxy resin system resulted in a durable, compliant design for the MRO market.

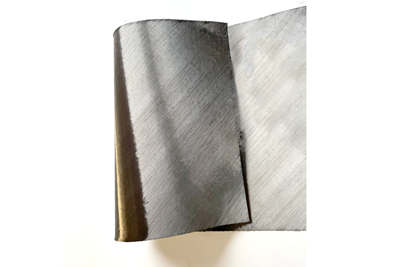

Read MoreAngeloni launches non-stitched multiaxial NCF fabric option

An adhesive grants the same stability of traditionally stitched composite fabrics, making Stratos suitable for use in a range of fibers and production processes.

Read MoreBlade2Circ project to facilitate sustainable next-gen wind blade designs

Coordinated by the Aitiip Technology Centre, the EU-funded project will design components to facilitate improved recyclabilty, exploring the performance of bio-based material options and novel degradation processes.

Read MoreEpisode 45: Scott Reeve; Corey Sechler, Creative Composites Group

Experts from FRP composites manufacturer Creative Composites Group discuss the role of composites in infrastructure projects today, including solutions for bridge rehabilitation and protecting waterfront structures.

ListenAitiip concludes HELACS project with waterjet cutting demonstration

Novel platform involving digital twin and human-robot collaboration succeeded in cutting a component from the 19th section of an A350 wing, highlighting its ability to enable composite structure recycling.

Read MoreMFFD longitudinal seams welded, world's largest CFRTP fuselage successfully completed

Fraunhofer IFAM and partners have completed left and right welds connecting the upper and lower fuselage halves and sent the 8×4-meter full-scale section to ZAL for integration with a cabin crown module and testing.

Read MoreLarge-volume VFGF extrusion printer facilitates modular composite cockpit

Queen 1 system from Q.Big 3D produced complete cockpit assembly of a full flight simulator in a little more than a month, enabling fast build speeds, high surface quality and dimensional accuracy.

Read More

.jpg;maxWidth=300;quality=90)