Large-volume VFGF extrusion printer facilitates modular composite cockpit

Queen 1 system from Q.Big 3D produced complete cockpit assembly of a full flight simulator in a little more than a month, enabling fast build speeds, high surface quality and dimensional accuracy.

Reiser Simulation and Training GmbH (Berg, Germany) recently commissioned Murtfeldt Additive Solutions GmbH (Murtfeldt AS, Kusterdingen, Germany) to produce a modular cockpit for a full flight helicopter simulator. The cockpit was successfully manufactured via Murtfeldt’s Queen 1 additive manufacturing (AM) system from Q.Big 3D (Aalen, Germany), a variable fused granulate fabrication (VFGF) process that achieves the production of large components via 3D extrusion printing.

The aim of this project was to overcome previous limitations of conventional manufacturing strategies; classic mold-based processes, especially for large-volume components, often incur high tooling costs and long lead times. And for a project like this one, according to the companies involved, such a project can usually take 3-6 months to complete. In addition, conventional fused deposition modeling (FDM) printers usually cannot produce large-volume 3D components, have uneconomical build rates and use material containing filaments which are often seven times more expensive per kilogram compared to a granulate 3D printer.

Alternatively, through production with a 3D extrusion printer, tooling costs are eliminated, new build strategies (such as new component geometries) can be realized with short amortization periods and, when compared with FDM printers, commercially available standard granulate without filaments in 3D printing can be used.

The resulting modular cockpit — all assembly components were 3D printed — is 2,260 × 1,780 × 1,705 millimeters. Made of aromatic polyamide with 25% glass fiber content (Q.mid GF25) for the cockpit frame, which gives high dimensional stability, temperature stability up to 200°C, high stiffness and optimized paintability, the cockpit weighs just 200 kilograms. The manufacture of all components took just over a month, however Murtfeldt AS expects shorter build times for a follow-up project by optimizing the process chain; a printer network comprised of several Queen 1 machines can also shorten the delivery time for time-critical requests — the longest single build job was almost 100 hours.

Michael Ortmann from Reiser Simulation and Training, responsible for design and development, says that 3D extrusion printing offered a number of potential benefits that previously did not seem possible. “Short time-to-market, high build speed, lightweight construction, bionics, functional integration and cost-effective manufacturing without the need for molds, along with the merits of using granulates, to name just a few aspects,” he lists.

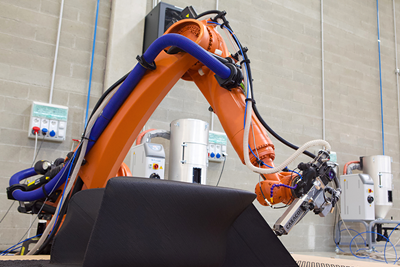

VFGF extrusion print head with variable nozzle diameter enables highly specific component construction

These are in addition to the control of distortion for large and complex components, tight-tolerance gap dimensions and high surface quality. Reassembling the de-mountable module at the user’s location was also optimized, along with the fact that two helicopter models (Airbus Helicopters H135 and H145) could be cost-effectively simulated using a conversion kit.

According to partners, the Queen 1 3D extrusion printer provides several features that made all of this possible:

- High surface quality, even in the case of a geometry’s strong overhangs.

- High degree of accuracy of fit of the components in the assembly (dimensional accuracy, small gaps) thanks to active temperature control of an outer chamber as well as the 3D printer’s build space

- Constant system temperatures, regardless of temperature fluctuations in the production hall itself.

- Variable nozzle control system which enables fast build rates, adapting to the particular characteristics of each geometry. Modes automatically change as needed.

In conclusion, use of the Queen 1 system is a low investment risk that eliminate post-processing costs, partners note, offering advantages over competing AM strategies, such as SLS or FDM printing.

“With the VFGF system technology from Q.Big 3D, we can specifically tap into further areas of application for the VFGF manufacturing strategy,” says Johannes Matheis, managing director at Murtfeldt AS. “If you master the entire process chain, complex, large 3D components with high repeatability and component quality on a new level are possible.”

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MorePultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreRead Next

CMS, Caracol collaboration targets large-format 3D printing market

Global development of LFAM technologies and applications will support end user’s adoption of 3D printing for composites.

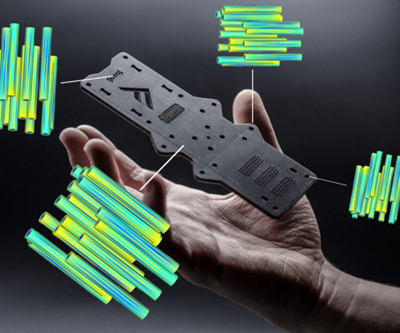

Read MoreMagnetic 3D printing the next generation of tailored composites

Fortify uses magnetic fields and digital light processing to produce tailored microstructures for high-resolution, 3D printed composite parts — and enables the next generation of multiscale, multifunctional composite metamaterials.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More