Materials

Gurit acquires Valplastic PET recycling operation

Gurit will acquire PET recycling production facilities from Valplastic S.r.l., with the goal of securing access to raw material supplies for its PET core products.

Read MoreUAMMI receives federal funds to grow advanced materials cluster

The Utah Advanced Materials and Manufacturing Initiative will use the funding to support small materials and manufacturing businesses in Utah.

Read MoreFirst shipment of CFRP engine nacelle cascade from Nikkiso Miyazaki Factory

With 90 percent of the cascade market, Nikkiso opened its new factory in 2018 due to increased demand.

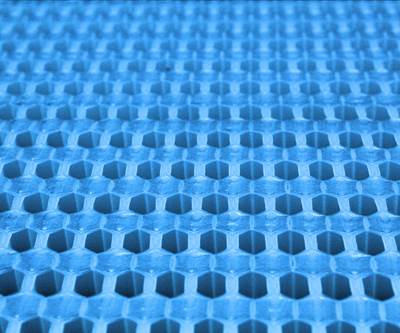

Read MoreEconCore breaking new ground with high-performance core materials

EconCore’s new ThermHex high-performance thermoplastics (HPT) honeycomb materials are well suited for applications requiring lightweight solutions but still needing to meet heat resistance and fire-smoke-toxicity (FST) requirements.

Read MoreAlpine Advanced Materials licenses Lockheed thermoplastic nanocomposite

Proven in military aerospace parts, the HX5 product targets metal replacement in single-aisle jetliners.

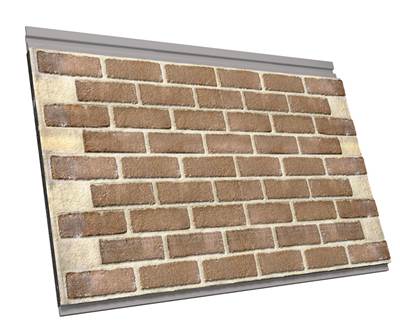

Read MoreArchitectural cladding composite unveiled

Arcitell, a manufacturer of residential siding products, has unveiled a lightweight fiber-reinforced polymer (FRP) panel that replicates traditional brick, stone or wood siding.

Read MoreStratolaunch aircraft completes first flight

On April 13, the world’s largest composite aircraft flew for 149 minutes in its initial flight test.

Read MoreSABIC's innovations of scale

SABIC at JEC World 2019 offered a virtual reality-based peek at its new Digital Composites Manufacturing line — a collaboration with Airborne aimed at automated, large scale laminate production of thermoplastic composite parts.

Read MoreMitsubishi Corp. completes shareholder agreement with ELG Carbon Fibre

The two companies aim to enhance global business development and provide a reliable supply of reprocessed carbon fiber.

Read MoreComposite manhole covers used in national LUKOIL Bulgaria update program

Fibrelite’s GFRP covers are said to improve safety for operators and site owners vs. corroded metal covers.

Read More