UAMMI receives federal funds to grow advanced materials cluster

The Utah Advanced Materials and Manufacturing Initiative will use the funding to support small materials and manufacturing businesses in Utah.

The Small Business Administration (SBA; Washington, D.C., U.S.) recently announced that it has awarded the Utah Advanced Material and Manufacturing Initiative (UAMMI; Clearfield, Utah, U.S.) federal funds to grow the advanced materials industry cluster in Utah. UAMMI was one of seven national organizations to receive the award.

The award is a result of the SBA’s objective to use public-private partnerships to align federal resources and programs with existing state and local resources, regional strengths and economic growth opportunities to build more prosperous small business ecosystems across the U.S. The SBA will grant UAMMI $500,000 over the next year with an option for up to four additional years to accomplish this objective.

To meet the program goals, UAMMI says it will continue its efforts with an emphasis on development of new technologies, financing opportunities, mentoring, matchmaking and networking efforts to help potential high-growth small businesses. Additional programs and events will also be created that will bring together Utah’s aerospace ecosystem of business and industry groups, academic institutions, workforce education, local governments, investors, economic development organizations, entrepreneur groups, technology specialists, and others to collaborate and share ideas. UAMMI says it will employ the services of LSI (Layton, Utah) to manage administration, reporting and new program implementation, and Grow Utah to manage the small business development and startup accelerator programs.

“We are thrilled to receive this award,” says Jeff Edwards, executive director for UAMMI. “The goal of UAMMI is to connect and grow Utah’s advanced materials and manufacturing industry across the state and these funds will be a tremendous help towards that. We are already implementing new initiatives and programs to accomplish these goals, especially in rural areas of the state.”

Across the country, cluster initiatives have become a point of focus for economic growth, UAMMI says. Clusters are considered regions with a heavy concentration of companies, suppliers and service providers within a certain industry, such as Utah’s advanced material cluster. Focusing on cluster growth often leads to businesses creation, new technologies and the development of new markets which lead to economic growth and job creation.

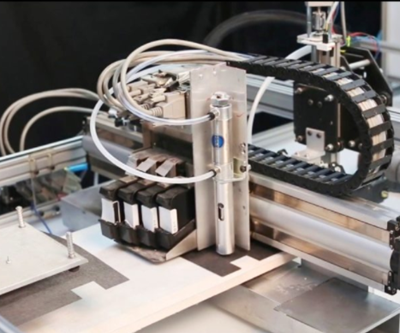

UAMMI was created in 2016 with funding from the Utah State Legislature to bring together public, private, community, industry and education partners to assure growth and sustainability of Utah’s advanced material and manufacturing industry. This includes more than 100 companies and over 12,000 jobs in Utah’s carbon fiber, advanced alloys, ceramics and 3D printing companies, resulting in a $1 billion economic impact to Utah’s economy.

“In just a few short years, UAMMI has already built and implemented many programs and initiatives that are connecting the advanced materials cluster in Utah,” says Angie Tymofichuk, deputy director for UAMMI. “We have built a robust supply chain software tool that allows Utah companies to connect, collaborate, and do more business with each other. We hold regular networking and learning events across the state to connect small and large businesses with each other as well as academia. With the help of theses SBA funds, we are excited to do even more to grow this vital industry cluster in Utah.”

Related Content

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreThermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreRead Next

UAMMI to produce 3D printed parts for Air Force

The Utah Advanced Materials & Manufacturing Initiative has been awarded nearly $1M in federal funds to produce carbon composite additive manufactured parts for the Air Force.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)