Out of Autoclave

Curve in the road: First curved pultruded auto parts

Thomas Technik + Innovation KG’s radius pultrusion process unlocks new possibilities for the automotive market and beyond.

Read MorePark Aerospace Corp. introduces mid-toughened epoxy resin system

The E-752-MTS mid-toughened 350°F (177°C) cure epoxy system is designed for primary and secondary aircraft structure applications.

Read MoreTooling Tech Group expands moldmaking facility

A 10,000-square-foot expansion to the Ohio-based thermoforming and compression mold manufacturing facility will be completed later this year.

Read MoreUAMMI, ElectraFly to make 3D-printed UAM aircraft parts

The Utah Advanced Materials and Manufacturing Initiative and a Utah-based aviation company to 3D-print CFRP parts for urban air mobility aircraft.

Read MoreComposites fare well at 2020 PACE Awards

This year’s automotive supplier award winners included composite bumper beam, liftgate and pickup box applications.

Read MoreCurved pultrusions enter production

Corvette CFRP rear bumper beam is the auto industry’s first use of new technology.

Read MoreCombination of automation, rigid foam core enable high-volume aircraft part production

A feasibility study demonstrates increased production capacity using Evonik foam core and automated manufacturing.

Read MoreHexcel carbon fiber prepreg selected for ultralight aircraft design

German aircraft specialist Flight Design is using HexPly M79 for composite parts on its F2 aircraft.

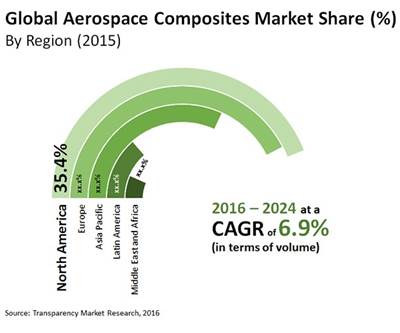

Read MoreTransparency Market Research releases Aerospace Composites Market report

Findings predict the global aerospace composites market value and trends between 2016 and 2024.

Read MoreWelded thermoplastic composite keel beam demonstrator achieved

EURECAT and partner companies complete Clean Sky 2 KEELBEMAN project, demonstrating TRL3 primary structure technology for future aircraft.

Read More