Out of Autoclave

Composites 4.0: Digital transformation, adaptive production, new paradigms

An evolving landscape of automation, sensors and AI software is not an end, but a means to achieve the cost, quality, efficiency and agility required for future manufacturing.

Read MoreThinking machines

Algorithm-based artificial intelligence, once only imagined, is here. It can do a lot of good.

Read MoreFLOTANT project to develop composite mooring cable system for deep water wind farms

Project partners are testing pultruded carbon fiber/thermoplastic profiles for use in a more cost-efficient, robust offshore wind farm mooring system.

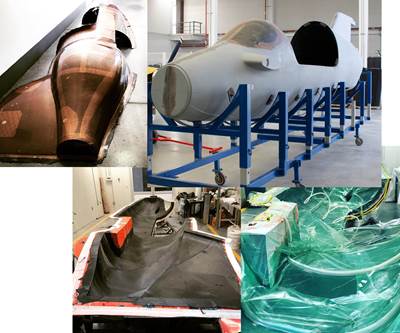

Read MoreFirst all-CFRP fuselage in Mexico

UNAQ and RHEM Composites help produce body of third prototype for Oaxaca Aerospace’s Pegasus P-400T.

Read MoreAimplas-led project develops thermoplastic prototypes

The RECONTRANS project adapts Arkema’s Elium thermoplastic resin for car, truck and rail applications.

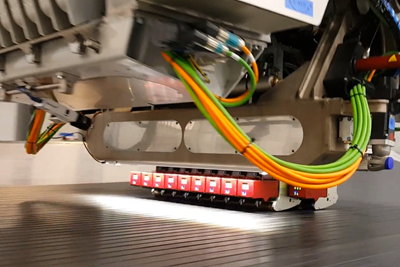

Read MoreHigh-rate, automated aerospace RTM line delivers next-gen spoilers

At Spirit AeroSystem’s Prestwick facility in Scotland, a glimpse of the future of aerocomposites manufacturing in a resin transfer molding line for A320 spoilers.

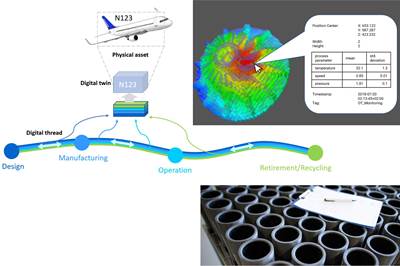

Read MoreDigital thread vs. digital twin

Visualizing the difference between digital representations and data flows and understanding the applications that are changing composites manufacturing and business models.

Read MoreA retrospective take on the composites industry and the pandemic

Dale Brosius reflects on recent composites industry trends and how they are impacted by the coronavirus pandemic.

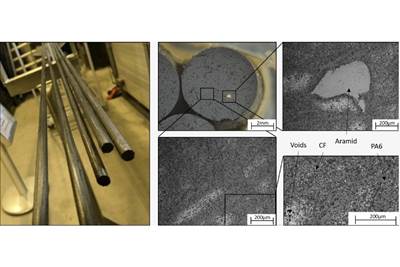

Read MoreNarrow UD tapes to bridge the ATL-AFP gap

Automated tape laying and automated fiber placement are similar, but not the same. Can narrow tapes provide a middle ground with advantages of both processes for next-gen aircraft?

WatchPlasan North America expands composite manufacturing solutions

The company plans to expand and invest in automated cutting technology to go with established prepregging, pultrusion and autoclave cure expertise.

Read More