Resins

Roth Composite Machinery becomes AZL partner for winding technology study

Roth Composites Machinery will support the joint study to evaluate potential composite technologies for composite pressure tanks.

Read MoreSino Polymer develops high-performance epoxy resin systems for prepreg applications

The one-component carbon fiber prepreg can be cured at 150ºC for 10 minutes, is suitable for structural parts requiring Tg within 120-140ºC and can be stored for up to 18 months at -18ºC

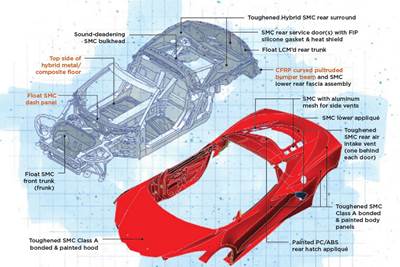

Read MoreComposites-intensive masterwork: 2020 Corvette, Part 2

Innovative composite materials trim mass, costs and noise on the high-volume mid-engine sports car.

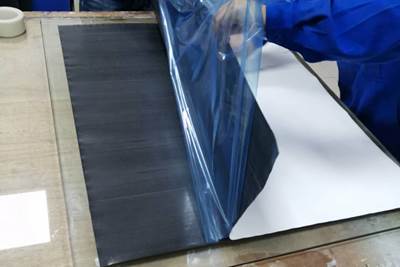

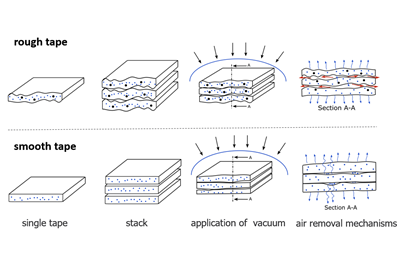

Read MoreTPRC investigates AFP in-situ consolidation alternative

The two-step process involves deposition of thermoplastic prepreg via AFP, followed by vacuum-bag-only (VBO). Research has already been completed in the qualitative stage.

Read MoreFibre Extrusion Technology FET-100 series reaches $20 million in sales

The multi-functional melt spinning system facilitates the development of precursor synthetic textile materials, as well as biodegradable composite materials.

Read MoreCAMX 2020 exhibit preview: Hexcel

Hexcel is showcasing its resins, thermoplastic UD tapes, epoxy prepregs and additive manufacturing technology.

Read MoreComposites complete IYRS heavy lift quadcopter demonstrator concept

Boasting a prepreg carbon fiber airframe, the HLAP concept became a platform for a variety of composite fabrication techniques.

Read MoreCAMX 2020 exhibit preview: DH Sutherland

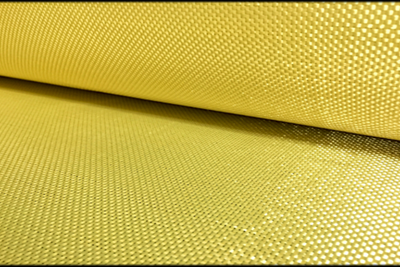

DH Sutherland is introducing technologies for chemical application and the manufacture of protective armor.

Read MoreRecycled thermoplastic composite rotorcraft access panel takes flight

Designed as part of the TPC-Cycle program, the flight-tested panel demonstrates a lighter, cost-effective, sustainable thermoplastic composite application.

Read MoreLeonardo and CETMA: disrupting composites for lower cost and environmental impact

Italian OEM and tier supplier Leonardo works with CETMA R&D to develop new composite materials, machines and processes, including induction welding for in-situ consolidation of thermoplastic composites.

Read More