RTM

Collins Aerospace invests in braiding technology, secures funding for next-gen components

The multi-axis composite braider will be used to prove out production for complex-shaped components like pressure vessels, battery enclosures and more.

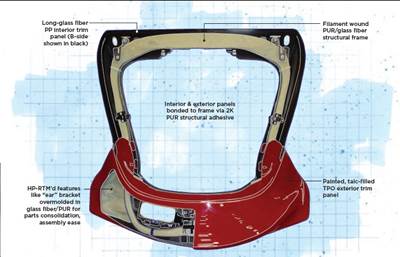

Read MoreLiftgate design puts modified filament winding to the test

Heavily modified winding process produces light, structural support frame for performance-critical liftgate.

Read MoreCarbon fiber automotive parts production industrialized via C-RTM process

Compression resin transfer molding overcame the difficulty in shaping CFRP car parts with development time reduced by 50%.

Read MoreCSP fine-tunes CF-RTM process, launches production programs

The carbon fiber RTM press will be installed at the CSP facility in Palmela, Portugal in order to run the company's first commercial applications using this technology.

Read MoreNext-generation composites materials and processes explored

A supplement with the November 2020 issue of CompositesWorld takes a close look at some of the technologies that are driving innovation in the composites industry.

Read MoreComposites Academy launches online training with hands-on exercises

Composites Expert and Institut de Soudure partner to provide interactive advanced composites training to students and professionals worldwide.

WatchBBG presents self-closing HP-RTM molds for CFRP compact hydrogen tank production

The autonomous concept, sufficient for series production, enables lower investment costs. Up to 15 cylinders can be produced simultaneously per operation.

Read MoreMVP launches Fast Flow LRTM process to speed closed mold part production

Increasing part production by decreasing injection times, Fast Flow LRTM is said to be capable of injecting a 50 square foot part in under four minutes using only one injection port.

Read MoreRevisiting the Fundamentals of Light Resin Transfer Molding (LRTM)

Like other closed molding composites processes, Light Resin Transfer Molding (LRTM) offers reduced waste and emissions, efficient materials use and a consistent and repeatable process. But LRTM requires less costly tooling and can still provide excellent cosmetics on both sides of a part in an efficient manufacturing process.

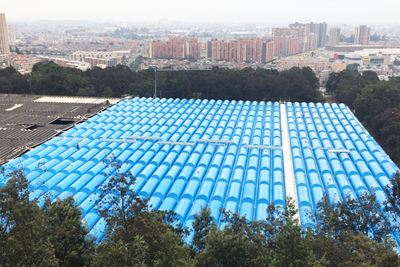

Read MoreSoling, Magnum Venus Products partnership produces LRTM composite domes

Incorporating the LRTM process enabled Soling to produce the largest LRTM part by volume manufactured in Colombia.

Read More

.jpg;maxWidth=300;quality=90)