RTM

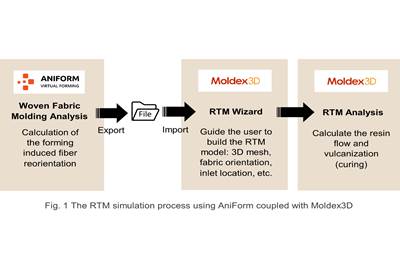

AniForm, Moldex3D develop interface tool for more accurate RTM prediction analysis

Interface enables users to consider forming-induced fiber reorientation in the RTM simulation model for a more accurate representation of the flow domain.

Read MoreTelene composite components selected for Ebusco electric city bus

Telene PDCPD polymer and low-density matrix produces durable body panels, offers lower part weight.

Read MoreAntich and Sons develop composite yarn-spinning technique for 3D-woven preform production

Culmination of a three-year project with AMRC which focused on creating stabilized, near-net shape preforms of variable thickness with efficient material use for aerospace and automotive.

Read MoreHuntsman Advanced Materials resin systems meet composite pressure vessel requirements

Araldite resin systems cover wet and towpreg filament winding and RTM manufacturing processes for increased productivity and greater part consistency.

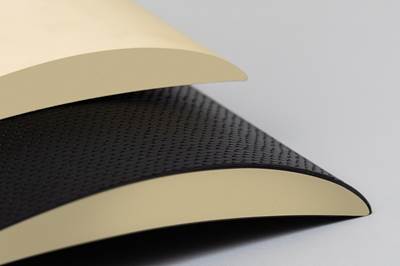

Read MoreHuntsman PU resin systems enable lightweight sandwich construction for automotive

Vitrox RTM and Rimline FC polyurethane systems to advance lightweighting, design freedom and simplified manufacturing opportunities.

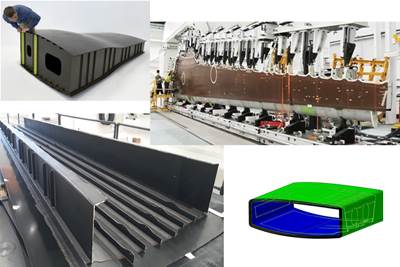

Read MoreFACC successfully develops novel composite flap system for Wing of Tomorrow

RTM’d five-meter-long, complex multicell flap prototype constructed via a highly integral, cost-effective manufacturing process.

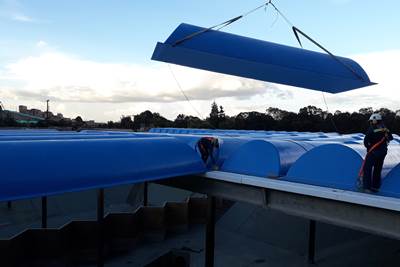

Read MoreLarge composite covers protect a lot of water

A massive concrete water storage facility in Bogotá, Colombia, gets a much-needed makeover with the resin transfer molding of 840 large composite domes that keep the water potable.

WatchBucci Composites completes testing of new carbon fiber wheel

Bucci’s new 22-inch high-performance automotive wheel is all carbon fiber and made via high-pressure resin transfer molding.

Read MoreThe path to OOA wings with minimal fasteners

A review of the quest to eliminate both the autoclave and mechanical fasteners in composite wing structures.

WatchHP-RTM as a means to reduce hydrogen tank packaging space and cost

BBG Gmbh & Co. KG has developed molds for producers of type IV CFRP tanks, integrating automation and sensors for faster, cheaper production of adjustable-length hydrogen storage cylinders.

Read More

.jpg;maxWidth=300;quality=90)