MVP launches Fast Flow LRTM process to speed closed mold part production

Increasing part production by decreasing injection times, Fast Flow LRTM is said to be capable of injecting a 50 square foot part in under four minutes using only one injection port.

Photo Credit: MVP

Magnum Venus Products (MVP; Knoxville, Tenn., U.S.) a global manufacturer of fluid movement and production solutions for industrial applications, launched on August 17 a new process for closed molding to increase part production by decreasing injection times. The new technique, named Fast Flow LRTM, is said to be a blend of MVP’s flex molding process and light resin transfer molding (LRTM) and uses collapsible resin channels for a faster resin flow.

According to MVP, the process resulted in the need to meet faster cure times for large parts using high viscosity resins such as fire retardant materials. Further trials and testing are currently underway with a large automotive manufacturer.

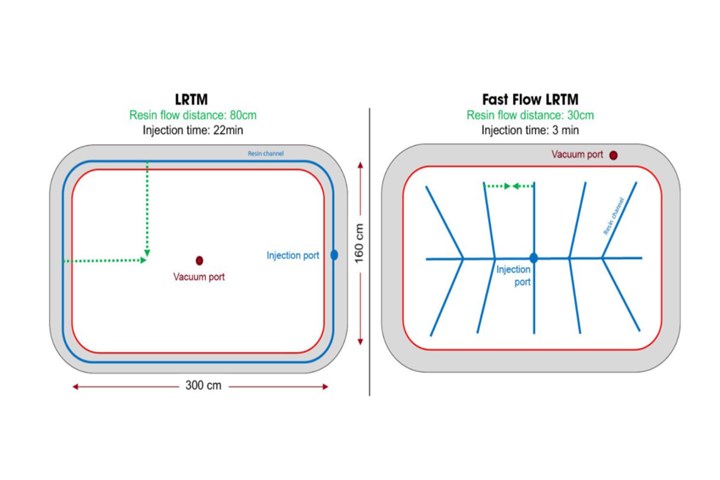

The company notes that when using a traditional LRTM mold, the resin flow speed is dependent on the distance between the resin channel and center of the part during injection. Utilizing the same silicone collapsible resin channels developed for its flex molding process, MVP’s Fast Flow LRTM technique uses a unique channel arrangement allowing channels to be installed closer together to decrease the resin flow distance and speed up injection times. This process is said to be capable of injecting a 50 square foot part in under four minutes using only one injection port, while also delivering a good back side surface aspect equivalent to traditional LRTM. By injecting the resin from the center to the border, the part demolds with a finished look and no visible resin channels, wasted materials or excess resin.

Fast Flow LRTM uses a unique resin channel design with the injection port located at the center of the part. By injecting the part from the center to the border, the part can be precisely finished with no trimming required. Photo Credit: MVP

Related Content

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

Pultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.