Thermoplastics

Stratasys, Champion Motorsport team up to test 3D-printed core technology

Stratasys proves out carbon fiber-wrapped, printed core for toolless, customizable manufacture, on aerodynamic prototype and production parts for a winning racecar.

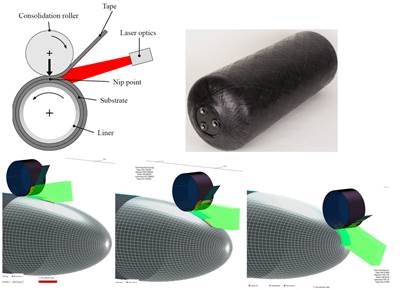

Read MoreOTOMcomposite develops software for Composites 4.0 production using laser-assisted tape placement and winding

Optical thermal optimization model (OTOM) software enables inline monitoring and control for improved part quality and reduced production time and cost of in-situ consolidated thermoplastic composites and Type IV pressure vessels.

WatchCAMX 2021 exhibit preview: Cygnet Texkimp

Cygnet Texkimp hopes to accelerate the use of composites in hydrogen technology with its new Filament Winding Innovation Hub, which will enable customers to explore every aspect of the filament winding process.

Read MoreCAMX 2021 exhibit preview: Airborne

Airborne’s integrated automated kitting system can pick composites plies directly from the conveyor cutter to sort, sequence and store them in a compact and fast buffer station.

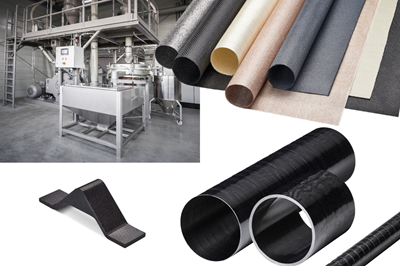

Read MoreCAMX 2021 exhibit preview: Ensinger

Ensinger offers a wide portfolio of products and services for thermoplastic composites, including its Tecatec materials range and polymer pulverizing and development services.

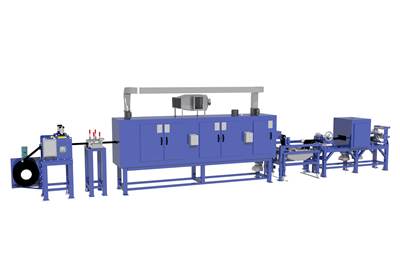

Read MoreCAMX 2021 exhibit preview: C.A. Litzler

C. A. Litzler thermoplastic prepreg machines are designed to enable lower-cost, thermoplastic prepregs for automotive and aerospace applications.

Read MoreTroubleshooting thermoforming of thermoplastic composites

Challenges with the thermoforming/stamping process and potential solutions addressing the associated parameters and complex material behaviors.

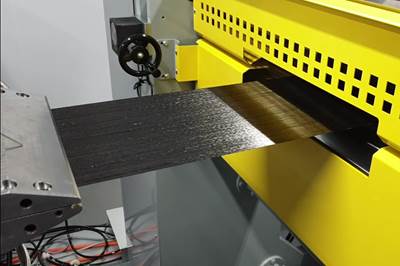

Read MoreCAMX 2021 exhibit preview: A&P Technology

A&P Technology’s new product offerings include slit tape thermoplastic fabrics that can be braided into fabrics up to 60 inches wide.

Read MoreLeveraging large-format AM fuels aerospace flexibility

Ascent Aerospace is known for producing high-quality metallic molds and tools for large aerostructures. Investment in large-format AM has expanded the company’s capabilities.

WatchDLR ZLP demonstrates new method for thermoplastic composite hydrogen fuel tank

AFP uses xenon lamp heating and inline QA to achieve innovative design which also uses ultrasonic welding.

Watch

.jpg;maxWidth=300;quality=90)