CAMX 2021 exhibit preview: C.A. Litzler

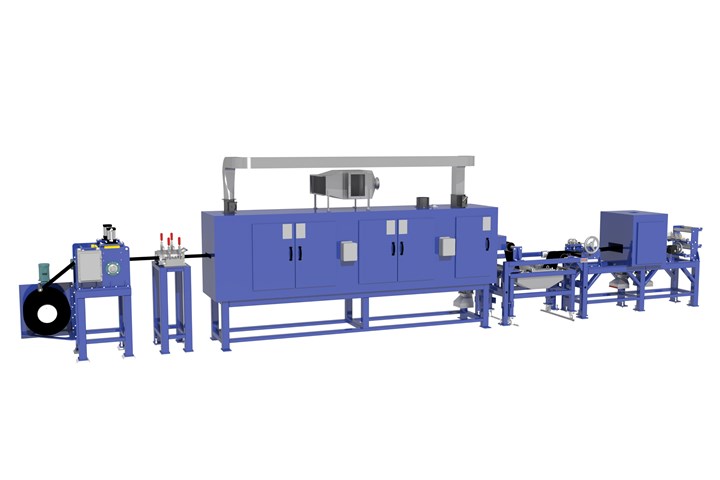

C. A. Litzler thermoplastic prepreg machines are designed to enable lower-cost, thermoplastic prepregs for automotive and aerospace applications.

C. A. Litzler Co. Inc. (Cleveland, Ohio, U.S.) highlights its improved, standard thermoplastic prepreg machines. The systems are available for use with water-based resins, various fibers and can produce prepreg at various widths.

Features of the system include:

- Fiber saturation and impregnation

- Stainless steel, recirculating slurry dip tanks using CFD modeling

- Mixing and distribution manifolds

- Submerged rollers to encourage wetting

- Water/solvent removal and resin pre-heating

- Infrared ovens are used because they do not disturb the resin distribution

- Heated die

- Precision machined to maintain/improve resin distribution

- Uniform temperature distribution across and along the web for uniform penetration and wetting

- Servo-driven compaction rolls for improved surface finish

- Litzler Automation control systems and graphical interface are reliable and easy to use.

C.A. Litzler also offers experience in dryer technology, superior compaction rolls and tow spreading experience.

Related Content

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

.jpg;width=70;height=70;mode=crop)