OTOMcomposite develops software for Composites 4.0 production using laser-assisted tape placement and winding

Optical thermal optimization model (OTOM) software enables inline monitoring and control for improved part quality and reduced production time and cost of in-situ consolidated thermoplastic composites and Type IV pressure vessels.

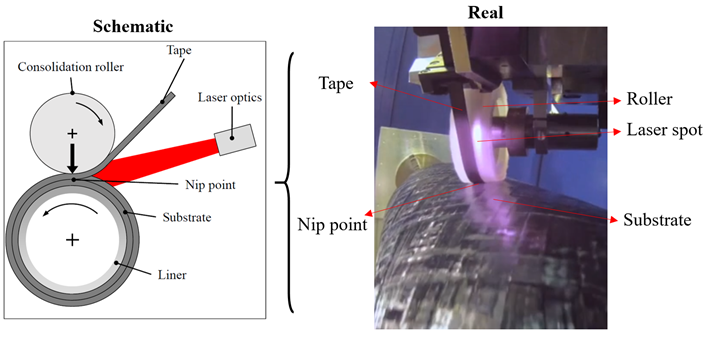

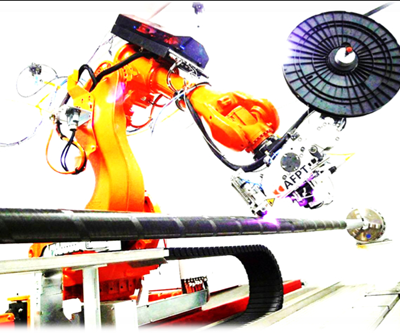

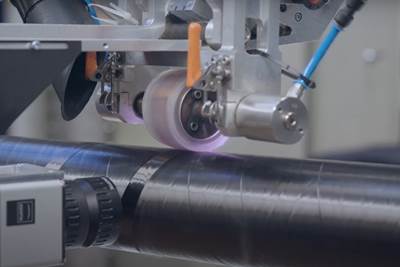

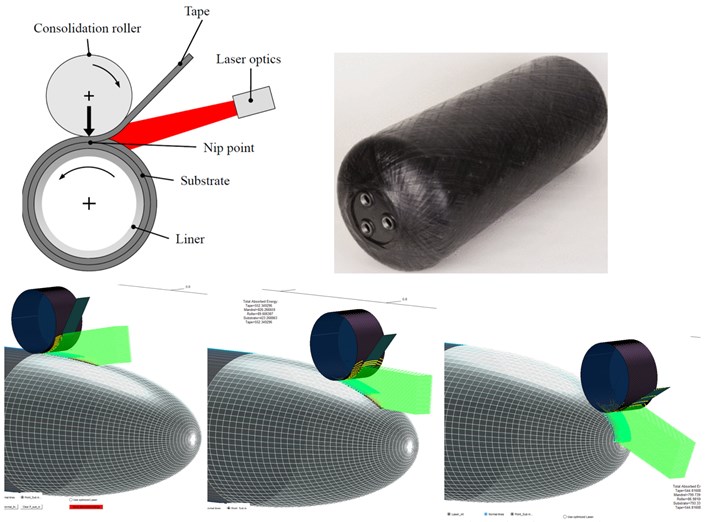

OTOMcomposite (Enschede, Netherlands) is a startup that provides engineering services and software for automated fiber placement (AFP), laser-assisted tape placement (LATP) and laser-assisted tape winding (LATW) technology. LATP and LATW are promising manufacturing techniques to produce advanced thermoplastic composite components (see Challenges of LATW). The main elements of this process are shown in Fig. 1. (For more details see, “Dry fiber placement: Surpassing limits”).

Fig. 1. The main elements of laser-assisted tape placement (LATP) and tape winding (LATW) processes. Photo Credit: “Temperature variation during continuous laser-assisted adjacent hoop winding of type-IV pressure vessels” by Amin Zaami, et. al.

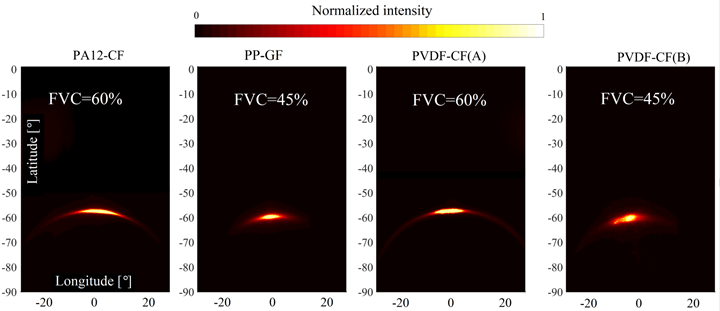

A fully automated single-step manufacturing can be achieved in these processes when the fiber-reinforced prepreg tapes are consolidated “in-situ,” which can reduce the production costs and eliminate post-consolidation or curing steps. Despite the advantages of these manufacturing techniques, it is a difficult task to predict and control the process, including the laminate temperature, crystallinity in its thermoplastic matrix, residual stress and overall quality. These are affected by the laser irradiation and reflections (see Fig. 2 below), local tooling geometry, consolidation achieved and the specific process parameters.

OTOMcomposite plays a role in the vital ability to thoroughly analyze process temperature during LATP and LATW, which is critical for the resulting part properties and performance.

Software development after ambliFibre project

Development of model-based inline process control for LATW/LATP processes was begun at the University of Twente within the EU-funded ambliFibre project. In close collaboration with Fraunhofer Institute for Production Technology (IPT, Aachen, Germany), more than 20 scientific publications were released during/after this project. In 2017, Dr. Amin Zaami saw the potential to produce a commercial tool for LATP/LATW processes and began developing the OTOM (optical thermal optimization model) tool, which combines advanced finite element modeling (FEM) and ray tracing.

Ray tracing is a technique that traces the path of light and simulates the effects of its encounters with objects during the AFP process. The ray-tracing optical model provides heat flux boundary conditions from the AFP laser for FE analysis. When combined with AFP control software — which typically does not focus on the bonding/heating phase, but solely on positioning and speed control — OTOM enables a faster path to optimized processing of the thermoplastic composite part and performance.

Replacing trial and error with 4.0 digital manufacturing

OTOM V.1.20 software is said to remove the trial-and-error phase in LATP/LATW processes. Depending on the complexity of the product, throughput can be improved by several hundred percent, especially for new product development (NPD). This in turn results in significant reductions in the time required for design, check-out trials and optimization of process parameters.

Fig. 2. Anisotropic reflection as a result of laser interaction with prepreg tape. Photo Credit: “Optical characterization of fiber-reinforced thermoplastic tapes for laser-based composite manufacturing” by Amin Zaami, et. al.

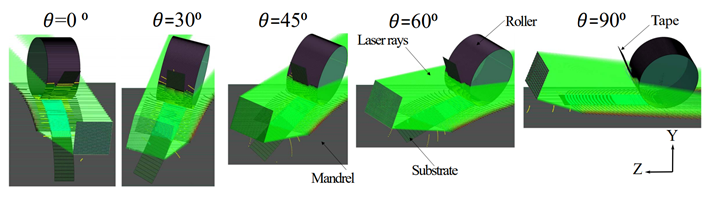

Fig. 3. Different laser irradiation geometries. Photo credit: “3D Numerical Modeling of Laser Assisted Tape Winding …” by Amin Zaami, et. al.

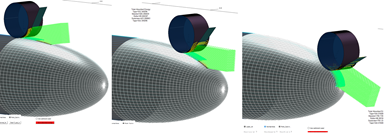

Fig. 4. Geometrically changing substrate curvature. Photo Credit: “New process optimization framework for laser assisted tape winding of composite pressure vessels: Controlling the unsteady bonding temperature” by Amin Zaami, et. al.

The LATP/LATW process is difficult to describe, predict and optimize due to the complex geometry, varying tool curvature and anisotropic optical and thermal properties of the fiber-reinforced thermoplastic composite tapes used. There are also issues such as unstable processing, machine downtime, smoke from overheating material, material degradation, squeeze-out (melted matrix pressed out beyond the edges of the tape) and the need to reduce production time. These can be resolved by a tool such as OTOM, which provides for inline monitoring, model-based control and Industry 4.0 digital manufacturing.

The long-term objective of OTOM is to achieve robust LATP/LATW part production by compensating for the variability in the manufacturing process to enable repetitive and predictable composite part properties and performance. OTOM has been validated using state-of-the-art numerical techniques and experimental studies. This tool is able to optimize every process parameter for a specific optimization goal (e.g., finding optimized laser power, finding optimized laser angle toward the heated zone) to get the highest process efficiency and product quality.

Interaction of the AFP laser with the composite laminate, temperature localization for a geometrically changing substrate and even tooling geometry effect can be fully simulated and optimized, all in one place. The multiphysics-based OTOM modeling tool reportedly paves the way for a digitalized LATP/LATW process, providing superior final product quality at minimized production time and cost.

OTOMcomposite

Launched in 2021, OTOMcomposite is providing services and software solutions to a growing number of organizations as business rebounds after the COVID-19 pandemic. OTOMcomposite offers engineering services to clients remotely or at their site, including production line and product quality assessment, technology consulting and tailored engineering software. These services are provided to companies and research organizations in the aerospace, oil and gas, transportation, automotive and green energy sectors. OTOMcomposite is also pursuing collaboration with other R&D departments for application of leading technologies related to composites, as well as participating in public and private funded R&D projects. For more information, contact OTOMcomposite@outlook.com.

Related Content

Composites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreComposites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreNCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreRead Next

INOMETA invests in new laser-assisted tape winding technology

Using the new automated manufacturing process, the company aims to expand its current thermoplastics product range with an eye toward mass production.

Read MoreAirbus establishes Zero-Emissions Development Centres for hydrogen tank manufacture

Bremen and Nantes sites will aim to achieve cost-competitive cryogenic tank manufacturing via metallic, composite technologies, and testing/installation capabilities to support future ZEROe launch.

Read MoreChallenges of laser-assisted tape winding of thermoplastic composites

Practical solutions for process-related challenges in LATW, which has great potential for pressure vessels and storage tanks.

Read More