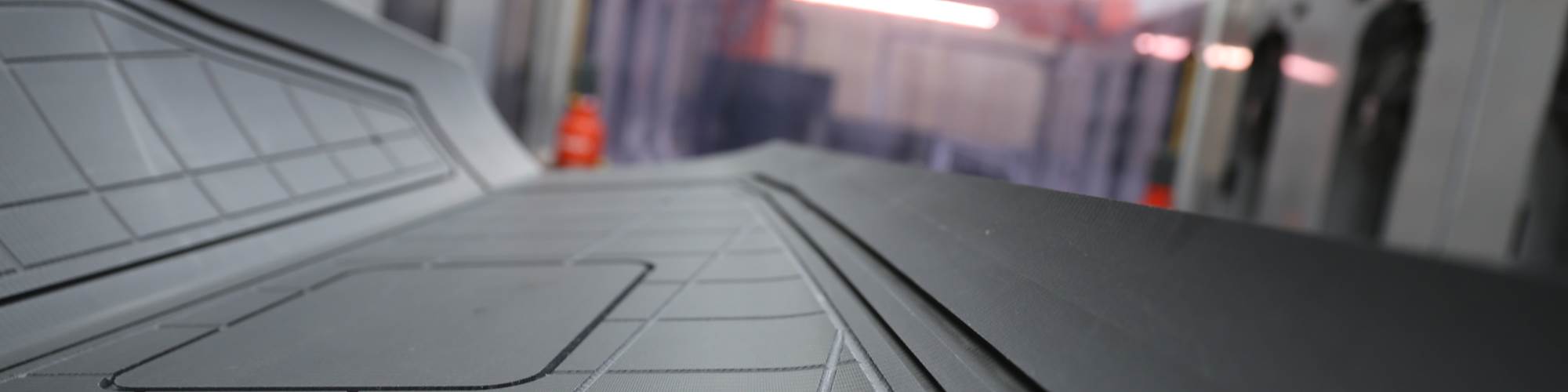

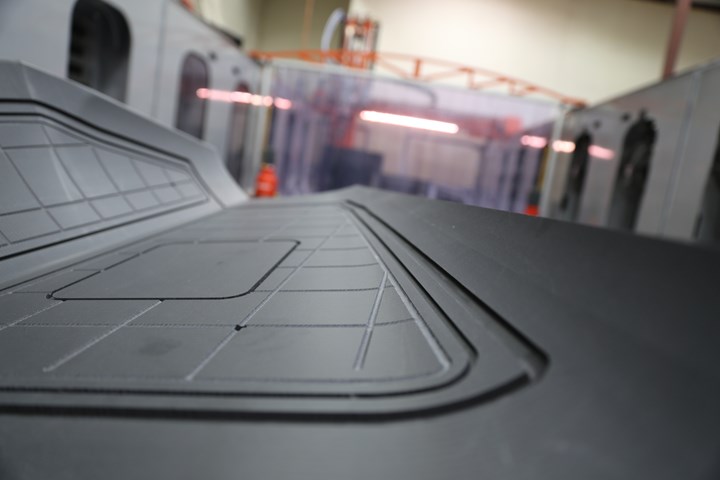

This fiber-reinforced thermoplastic mold was produced by Ascent Aerospace at its Santa Ana, Calif., U.S., location using the company’s new Thermwood LSAM large-format additive manufacturing and finishing system. Ascent uses the LSAM to fabricate tools, fixtures and molds for room temperature and thermal cycling applications. Photo Credit: Ascent Aerospace

Ascent Aerospace (Macomb Township, Mich., U.S.; Santa Ana, Calif., U.S.) bills itself as the world’s largest aerospace tooling supplier, providing mostly metallic solutions for molds, assembly and trim and drill fixtures. The company’s moldmaking focus is on large aerostructures, like nacelles, wings, fuselages, spars, stringers and frames. Its trim and drill fixtures are used in CNC machining, robotic welding, automatic presses, inspection systems and assembly applications.

In 2018, the company began to consider adding large-format additive manufacturing to its Santa Ana portfolio and conducted an evaluation of systems, materials and applications on the market. Recognizing that it needed a large-format machine that could produce tools of a size typical for Ascent, in 2019 the company invested in an LSAM system from Thermwood (Dale, Ind., U.S.) — a 10 x 40-foot dual-gantry/dual-function, extrusion-based additive manufacturing cell that includes a large-format printer on one end and CNC machining capabilities on the other end. The system was installed in the second quarter of 2020, just as the pandemic began.

Sean Henson, global product manager, composites and additive manufacturing at Ascent’s Santa Ana location, says that although the timing was not ideal, Ascent was able to put the new LSAM to immediate work and began a multi-month effort to understand the capabilities, advantages and limitations of large-format AM in a toolmaking environment.

The learning curve and pandemic notwithstanding, Ascent delivered more than 20 tooling programs through the LSAM in the first year of its operation. Most of this work centered on production of fixtures, vacuum trim tools, prototypes and molds. For trim fixtures, Ascent primarily used an ABS resin from Techmer (Clinton, Tenn., U.S.) reinforced with 20 wt-% chopped carbon fiber. For moldmaking applications that require high-temperature cycling, Ascent prints with either polyethersulfone (PESU) or polyetherimide (PEI), both reinforced with chopped carbon fiber. Ascent has also, in a few applications, printed with polycarbonate (PC) because it offers slightly better properties than ABS and is a higher temperature performer. Henson says about 75% of the products made with the LSAM system are for room-temperature use, with the balance destined for temperature cycling. Of the molds that see temperature, some are mold masters and designed for <200°F environments, while others are designed for autoclave cure up to 350-400°F and 100 psi pressure.

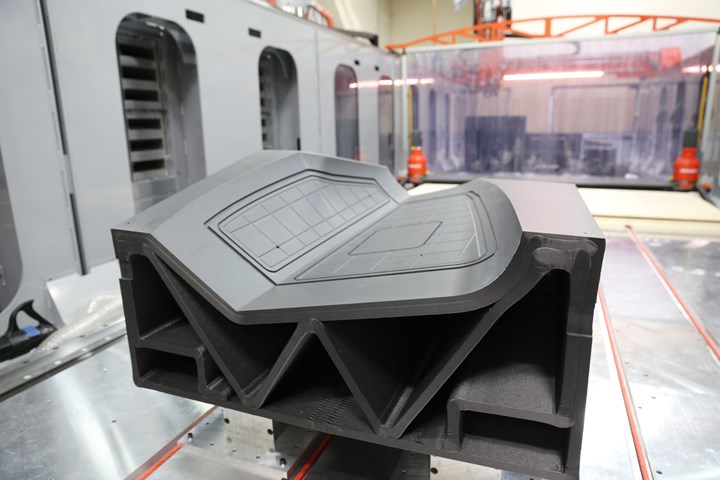

So, what is the biggest advantage of LSAM? Speed and cost, says Henson. The lead time for an LSAM-made mold is half that for a metallic mold and material costs are less as well. “So speed is a huge one,” Henson says. “The reason that we went towards large-format additive was the material deposition rates and just the amount that we can build because our tooling is big. We can build some really big stuff really quickly. Our prints typically take between eight and 15 hours. In that time, we’re able to fabricate tools that can weigh up to 1,000 or 1,500 pounds of material. So, we’re looking at a footprint 13 to 14 feet long and 5 feet tall and we’re printing that in less than a day.”

Further, because Ascent has a dual-gantry/dual-function machine, it can print and finish molds simultaneously. “It does have the dual gantry,” Henson notes. “So we’ve got the ability to print on one half of the system and machine on the other half, and we can run those independently so we can be printing something that’s 10 to 15 feet long and machine something on the other side of the table that’s the same length, and run those operations simultaneously.” Also, Henson notes that because printing and finishing are on the same machine, the “router knows where the printer laid material down,” which speeds up the downstream machining process. For the right application and the right customer, says Henson, 3D printing provides a finished, usable product more quickly than is possible with any legacy material or process.

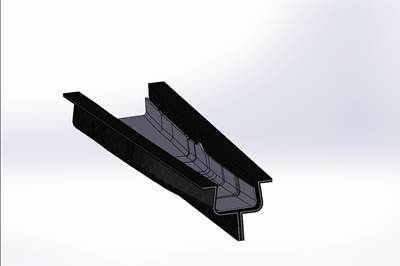

The downsides? There are a couple, starting with the near net-shape aspect of 3D printing with a large extruder. “Everything we do is an overbuild with post-process machining,” Henson points out. “The trade-off that you make to put down as much material as the LSAM can as quickly as it can is the resolution of your prints. Our [extruded] beads are over three quarters of an inch wide and about a quarter inch tall. When you look at an as-printed piece, you can see those scallops, you can feel them. It’s an FDM dot layer, just blown up 100 times. And so for any type of smooth surface, whether it’s a temperature mold or a trim tool or even just a smooth prototype, there is some machining component involved to get a finer finish, especially for aerospace applications.”

Ascent’s 10 x 40-foot LSAM is a dual-gantry machine, which allows simultaneous printing in one half of the system and finishing via CNC in the other half. The LSAM has a deposition rate of 150-200 lb/hr and can print a near net-shape mold in just 15-18 hours. Ascent says this technology is a good fit for applications that don’t require the cost, quality and time of metallic fixtures and molds, but do require a level of quality and finish better than foam tooling can provide. Photo Credit: Ascent Aerospace

The second challenge rests in the fact that a carbon fiber-reinforced thermoplastic does not behave like Invar, aluminum or steel. The anisotropic nature of fiber-reinforced materials means their highly variable coefficient of thermal expansion (CTE) in a mold during thermal cycling can make it difficult to produce finished parts that meet dimensional spec. “That’s the big challenge we have on the design side and on the printing side,” Henson says. “Customers will give us a final shape and then we need to do a little bit of modeling work to figure out what the tool needs to look like both from a structural standpoint and from a CTE standpoint.” Henson says Ascent is learning to adjust for CTE variability in its designs, relying on trial and error, data derived from previous printing programs and customer feedback to help it refine its design capabilities.

Henson says this cost/benefit combination — CTE versus speed and cost — means that its LSAM capabilities must be deployed carefully, weighing the application requirements against the deliverable deadline. “This is a really good way to get a tool in a matter of weeks, as opposed to a couple of months,” Henson says. “But just be aware of the trade-offs. If you’re expecting it to react like an Invar tool, where you’re going to get a perfect part, it’s not going to do that. But for a lot of customers, and especially a lot of R&D and development customers, it’s a really good way to get a quick tool.”

That said, at least one of the molds that Ascent printed from its LSAM is already in use for production of a flying aircraft, with more surely to come. And the company envisions a day, not too distant, when it maxes out its LSAM capacity and needs to add more. The company’s ownership, says Henson, sees the potential of 3D printing and is highly supportive of its expanded use.

Related Content

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreIndustrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreRead Next

Hybrid, large-format additive tooling: Lighter, faster, less costly molds for big parts

Additively manufactured cores, CFRP face skins produce large tools for prototype, low-volume aerostructure parts.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More