Welding

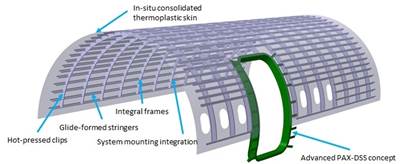

Manufacturing the upper half of the Multifunctional Fuselage Demonstrator (MFFD)

Proving industrial reliability for low-cost thermoplastic composites production using AFP in-situ consolidation, as well as continuous ultrasonic and resistance welding.

WatchMoving forward on the Multifunctional Fuselage Demonstrator (MFFD)

Clean Sky 2’s MFFD program continues to move toward its goal of delivering a welded, thermoplastic composite fuselage demonstrator using next-generation manufacturing processes.

Read MoreAutomated aerocomposites production: Liquid molding or welded thermoplastic?

Two materials and process approaches are demonstrated for CFRP bulkhead production.

Read MoreLeonardo and CETMA: disrupting composites for lower cost and environmental impact

Italian OEM and tier supplier Leonardo works with CETMA R&D to develop new composite materials, machines and processes, including induction welding for in-situ consolidation of thermoplastic composites.

Read MoreAimplas-led project develops thermoplastic prototypes

The RECONTRANS project adapts Arkema’s Elium thermoplastic resin for car, truck and rail applications.

Read MorePremium AEROTEC displays thermoplastic CFRP pressure bulkhead

Demonstrator at Paris Air Show advances resistance welding toward serial manufacturing of composite fuselage shells for next-generation aircraft.

Read More