Wind/Energy

The color purple: The "no complaints" movement

So, I finally heard about the “no complaints” movement the other day, which involves wearing a rubberized purple bracelet and switching it from one wrist to the other whenever one utters a negative word.

Read MoreThe future of composites education

Experts weigh in on the weighty problems this industry faces as it confronts a serious shortage of trained personnel.

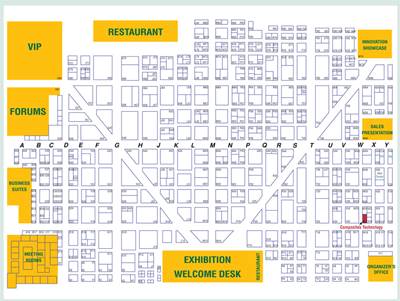

Read MoreCOMPOSITES+POLYCON 2009 Showcase

Despite the deepening recession, composites pros returned to the show in its new time slot to explore the wealth of products and services collected here.

Read MoreResin systems update: The greening of thermosets

Thermoset resin formulators seek environmental benefits as customers demand reduced cost and increased performance.

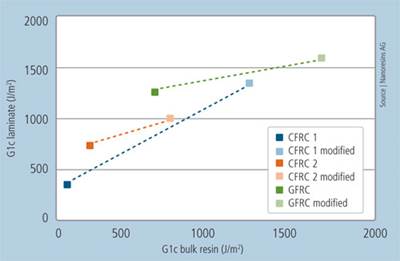

Read MoreSAMPE Europe/JEC Composites 2009 preview

SAMPE Europe’s 30th annual spring conclave and the nearby JEC Composites Show characterize the latest in material and process technologies.

Read MoreJEC Composites 2009/SAMPE Europe preview

Organizers predict good turnout in poor economy for annual Paris tradeshow.

Read MoreIs it really low-tech vs. high tech?

I’ll bet that a lot of folks who read this column regularly — assuming I’m lucky and lots of folks are reading — have spent their entire careers working with E-glass without ever thinking they were high-performance geeks, too. To them, welcome to the club!

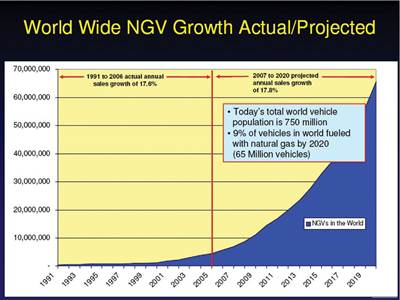

Read MoreThe outlook for composite pressure vessels

Environmental and economic pressures continue to drive growth in the market for composite pressure vessels used in personal and public transportation applications.

Read MoreAircraft delays alter carbon fiber supply/demand balance

When Boeing announced in early December that it was officially pushing back the first flight and the first delivery of the 787 Dreamliner to second quarter 2009 and first quarter 2010, respectively, one of the first questions that circulated among our staff centered on the issue of carbon fiber supply.

Read More

.jpg;maxWidth=300;quality=90)