Wind/Energy

JEC World 2022, Part 2: Recycling, natural fibers and additive manufacturing

CW associate editor Hannah Mason recaps several technologies seen on display at JEC World 2022, including new developments from Bcomp, Massivit 3D, Gen 2 Carbon and more.

Read MoreIberdrola, FCC Ámbito launches EnergyLOOP for wind turbine blade recycling

Industrial-scale blade recycling plant setup in Navarre, Spain is to enable the energy transition by recovering composite wind turbine blade components and considering their reuse.

Read MoreJEC World 2022, Part 1: Highlights in sustainable, digital, industrialized composites

JEC World 2022 offered numerous new developments in composites materials, processes and applications, according to CW senior editor, Ginger Gardiner, most targeting improved sustainability for wider applications.

WatchExperts forecast taller, more economical wind plant designs in the future

NREL researchers elicited more than 140 professional opinions concerning 2035 expectations, noting onshore wind turbines reaching 130 meters and plant sizes up to 1,100 MW.

Read MoreMoving toward next-generation wind blade recycling

Suppliers, fabricators and OEMs across the composite wind blade supply chain ramp up existing technologies, develop better reclamation methods and design more recyclable wind blades.

Read MoreJoint declaration to lead European offshore wind capacity to 150 GW by 2050

Germany, Belgium, the Netherlands and Denmark cooperate to increase wind capacity, expand large-scale energy hubs and explore green hydrogen, all of which will affect carbon fiber demand.

Read MoreAmerican Clean Power issues annual renewable energy report

In 2021, the U.S. surpassed 200 GW of renewable energy capacity including wind, solar and battery storage. However, bottlenecks caused by inflation, supply chain issues and other components threaten the ability to reach climate targets.

Read MoreU.K. wind turbine blade recycling project, PRoGrESS, commences

The three-year project seeks to deliver a circular model for wind turbine blades with the building of the U.K.’s first recycling pilot plant and commercialization of University of Strathclyde’s recycling method.

Read MoreBelzona 5711 paste fortifies and repairs wind turbine blades in-situ

Easy-to-apply, fast-curing, hard-wearing Belzona 5711 directly overcoated with Belzona 5721 optimizes onshore and offshore wind blade leading-edge repair and protection across a broad temperature range.

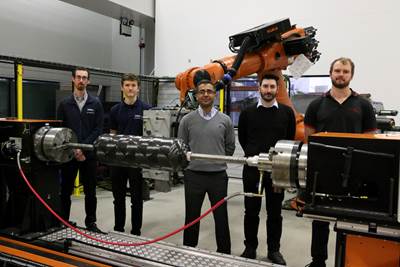

Read MoreAMRC, industrial partners develop Type IV hydrogen tank for long-haul vehicles

In the 12-month project, the University of Sheffield Advanced Manufacturing Research Centre (AMRC) has built prototype tanks and worked to build a secure U.K. supply chain.

Read More

.jpg;maxWidth=300;quality=90)