Wind/Energy

Gazelle Wind Power teams up with Ferrofab for hybrid floating wind platform

Center for Manufacturing Excellence to be established in UAE to accelerate manufacture and deployment of next-generation offshore wind platforms.

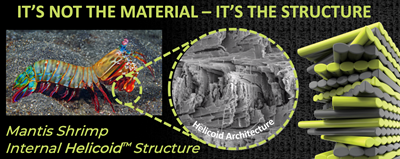

Read MoreCAMX 2022 exhibit preview: Helicoid Industries

Helicoidal fiber-reinforced composites are the inspiration for new developments in rain erosion-resistant substrates, improvement in damage tolerance and sustainable composites.

Read MoreBlue Wind manufactures 1,000 nacelles in 28 months with one mold

Manufacturer combined speed and quality for composite wind turbine nacelles during the pandemic, producing 10 nacelles per week.

Read MoreNPROXX expands business into the U.S.

Type IV tank manufacturer cites national hydrogen investment, more supportive vehicle regulations and general expansion opportunities as reasons for its 2023 U.S. establishment goals.

Read MoreVestas implements composites 3D printing to increase efficiency for blade alignment tools

A Markforged digital repository and multi-material 3D printers enable faster, more accurate and less costly manufacture of a variety of tools and blade components across Vestas sites.

WatchCarbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MoreSwancor, Siemens Gamesa collaborate on advancing recyclable wind blade technologies

Through Swancor’s recyclable thermosetting resin technologies, the recyclable resin and composites can be reused, assisting Siemens Gamesa in moving towards its goal of providing fully recyclable wind turbines in Taiwan.

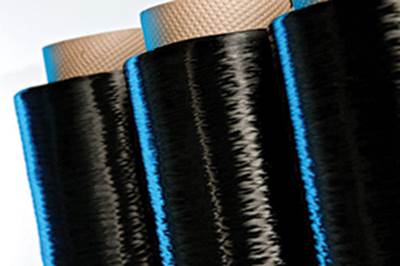

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read More

.jpg;maxWidth=300;quality=90)