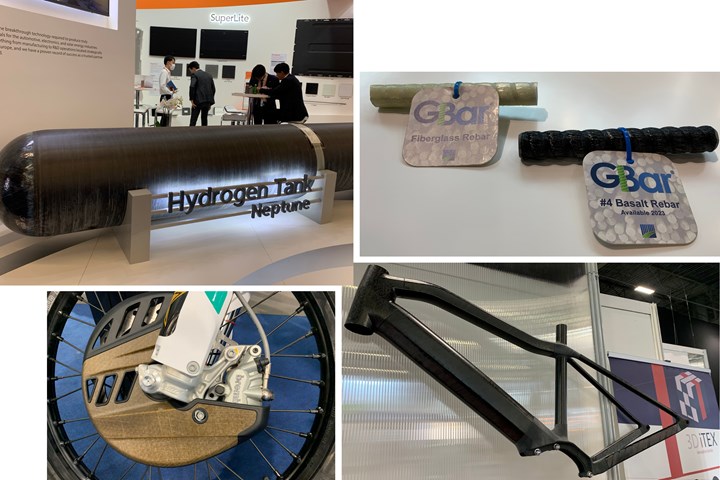

Displays at JEC World 2022 included (top left, clockwise) Hanwha Solutions Neptune CFRP hydrogen storage tank, GBar composite rebar, 3DiTex thermoplastic CFRP bike frame and a motorcycle brake cover using Bcomp flax fiber fabric in an epoxy composite overmolded with CF/PA in a one-shot process using a CONEXUS layer by KTM e-technologies. Photo Credit: CW.

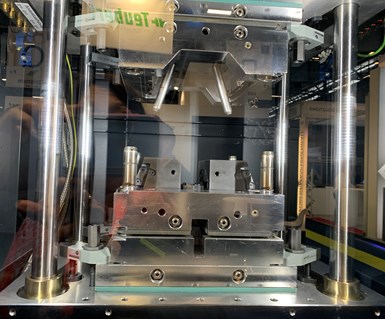

More sustainable, automated resin injection

Techni-Modul Engineering (Coudes, France) highlighted its automated Smart Injection system for resin transfer molding (RTM) small parts. Resin is directly injected into the mold, infusing dry preforms without conventional tubing, which eliminates these consumables, the waste resin they store and required cleaning. Benefits claimed versus standard injection systems include: 50% labor reduction (15 vs. 30 minutes), 89% consumables reduction (€6 vs. €55) and 80% resin waste reduction (40 vs. 200 grams).

Industrialized performance parts production, integrated electronics

Biontec (Gallen, Switzerland) designs and manufactures high-performance composites using tailored fiber placement (TFP) and RTM. Production volumes range from 100 to 100,000 parts/year. The company is on its fourth generation of carbon fiber-reinforced polymer (CFRP) bike brake levers and clamps, which use automated stitched preforms that enable reinforced, molded-in holes and 1,200 parts per week. Biontec also showed off a laser scanner drone used for construction sites that features molded-in LEDs, antennas and cables for radar modules and radiolucent composite windows for GNNS antennas, reducing weight and increasing durability and performance.

Biontec carbon fiber composite parts for bike lever (left, center) and laser scanner drone (right). Photo Credit: CW

Novel automatization for 3D composite tubular/hollow structures

3DiTex (Canéjan, France) is a startup co-founded by Bertrand Laine — previously technical director for RT2i and currently CTO for NOBRAK — together with Aymeric AZRAN (CEO of NOBRAK). Its patented technology reportedly produces multilayer hollow or tubular structures that can be formed into complex shapes as preforms, during molding or thermoformed after consolidation. This technology includes machines capable of continuously producing textiles (>1 meter per minute) as well as algorithms to automate the transformation of CAD object geometry into a machine program with optimized topological trajectories. 3DiTex is targeting thermoplastic composite tapes to dramatically reduce cost, enabling new mass production applications for composites, up to 100,000 parts/year, as well as future use of bio-based matrix and/or fiber materials for improved sustainability. It is also working with other materials like ceramic fiber tapes to produce ceramic matrix composite (CMC) parts.

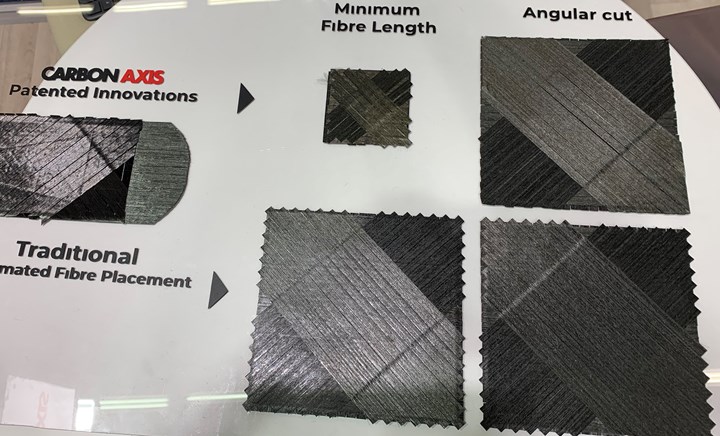

AFP for the masses

Carbon Axis (La Rochelle, France) has developed the XCell turnkey automated fiber placement (AFP) cell for SMEs who don’t have robotic skills in-house. Its compact AFP head sits within a temperature- and humidity-controlled cell with a creel below to store the towpreg and slit prepreg tape it uses to create preforms up to 1 x 0.5 x 0.5 meter. The whole system measures 1.6 x 1.6 x 2 meters and can place two 5- to 15-millimeter-wide tows/tapes at minimum lengths with angular cuts (between -45° and +45°) not typically seen in large AFP machines, offering minimized waste and automated, net-shape preforms for small parts manufacturing. The XLay all-in-one software solution integrates part design, layup design, robot simulation and robot coding for a turnkey, reportedly ready- and easy-to-use system, priced at roughly $200,000. See the XCell in action in this March 2022 video.

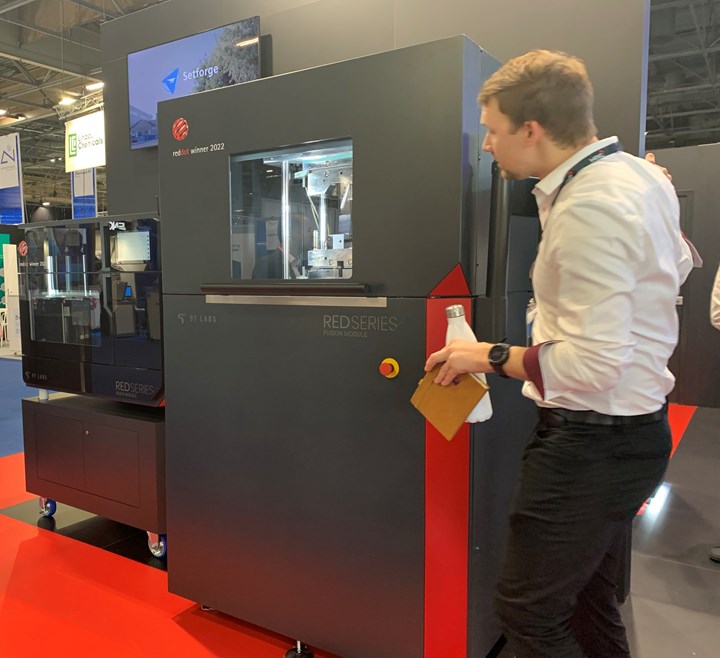

Continuous fiber additive manufacturing of high-volume, high-quality parts

9T Labs (Zurich, Switzerland) demonstrated its Build Module and Fusion Module for 3D-printed continuous fiber parts with up to 60% fiber volume and <1% voids. CW’s focus was the Fusion Module, which can apply temperature and pressure up to 400°C and 20 bar, welding multiple printed preforms into single, function-integrated parts with superior surface finish. The system architecture enables connecting sensors for continuous process monitoring and control. The company is developing/preparing to publicize applications in aerospace (interior components, brackets, and engine components), advanced air mobility (rib stiffeners for wings), medical (surgical instruments), luxury (watchmaking, eyewear) and human exoskeletons (ergonomic support for lifting heavy loads). 9T Labs has delivered commercial systems to research centers/universities, aerospace Tier 1 suppliers and the metal forming industry via Setforge, see https://youtu.be/793RRGwVRq8.

Revolutionizing composites repair and production with induction heating

Msquare (Stuttgart, Germany) is a spin-off from the German Aerospace Center (DLR) advancing the use of induction heating for composites repair, heated tooling, parts preforming and production. It also offers resistance heating and hot air fan solutions for applications where induction is less optimal, such as in-field repairs to wind blades. On display at JEC were Msqaure’s variety of controllers, including multi-zone hot bonders and compact, smart/multitasking RedZero units. Its FlexIn Heat induction blankets induce eddy currents in thin, metal sheets placed only where heat is needed. Temperatures up to 400°C are applied almost immediately and homogeneously for fast heating and cooling without the need for equilibrium-establishing dwells. FlexinHeat can also be applied to platens and tools, reducing energy use by >50% versus cartridge heaters while dropping cycle times significantly. Watch CW for more about this technology including the September 2022 issue.

Thermoplastic composite floor beam for the MFFD

Mikrosam (Prilep, Macedonia) showcased a thermoplastic CFRP floorbeam developed in a two-year project with GKN Fokker (Hoogeveen, Netherlands), the project leader for STUNNING (SmarT mUlti-fuNctionNal and INtegrated thermoplastic fuselaGe), which is constructing the lower fuselage section of the all-thermoplastic, 8-meter-long, 4-meter-diameter Clean Sky 2 Multifunctional Fuselage Demonstrator (MFFD). GKN Fokker has installed a Mikrosam eight-axis robotic AFP machine, slitting equipment for thermoplastic prepregs and a custom-engineered thermoplastic consolidating machine. Mikrosam used its in-house systems to demonstrate floor beam production capability to GKN Fokker and produced the parts exhibited at JEC. Watch for more details in CW’s October 2022 issue.

Resin infused rudder flap passes the test

FiberCore Europe (Rotterdam, Netherlands) displayed a resin infused, glass fiber-reinforced composite rudder flap developed in the RAMSSES project. The 1:6 scale demonstrator was tested successfully to 225% of ultimate design load. The design is aimed at ~400-meter-long container ships and offers 30% weight savings versus steel and double the lifetime. Read more about RAMSSES, the InfraCore helideck and how this technology is helping remove barriers to lightweighting ships.

Composite solar cells

Porcher Industries (Badinières, France) displayed a composite solar panel developed in collaboration with the French Alternative Energies and Atomic Energy Commission (CEA). The solar cell replaces the heavy and impact-sensitive plate glass front sheet with a glass fiber-reinforced thermoplastic composite layer. Porcher Industries explained in a LinkedIn post that it was challenging to develop a laminate thin and clear enough for solar cells beneath to function effectively. One key was a glass fiber treatment for improved adhesion with the thermoplastic matrix. Targeted benefits include reduced cost and weight and increased impact resistance to enable a wider range of renewable solar energy applications.

“Puzzle-cut” SAERfoam for complex curve drapability, fast assembly

SAERTEX (Saerbeck, Germany) displayed a variety of products and applications. One of the more eye-catching displays was its SAERfoam-cored wind blade segment featuring its patent-pending “puzzle” pattern for drapability and improved assembly of precut kits. As explained in a June 2021 webinar, SAERfoam does not use a scrim, but instead inserts glass fibers into the foam for improved connection to sandwich skins. The drapable “puzzle” pattern enables conformability to complex curves, which facilitates dry layup for infusion and reduces resin consumption. Larger, dog bone-shaped pieces can be cut and used to quickly secure abutted foam pieces during dry layup. The cut pattern also aids with excellent resin flow and wetout during infusion.

Hydrogen tanks proliferate

CW has been writing about the impact of the green energy transition on composites, specifically the rapidly growing hydrogen economy’s need for compressed gas and cryogenic liquid hydrogen storage tanks and how that will affect the carbon fiber supply chain. Spoiler alert — the estimated need for millions of tanks by 2030 is already putting a strain on the supply of composite pressure vessels as well as the high-strength carbon fiber they require. Accordingly, hydrogen storage tanks were popular in JEC World 2022 displays:

- A Type IV compressed gas tank made by MIKROSAM using its automated towpreg winding system for H2storage.nl

was on display as well as a smaller tank made using wet filament winding. For more details, see CW’s recent MIKROSAM webinar.

- Type IV compressed gas tanks were displayed by Hanwha Solutions (Seoul, South Korea), which recently acquired composite tank manufacturer Cimarron Composites (Huntsville, Ala., U.S.).

Photo Credit: CW

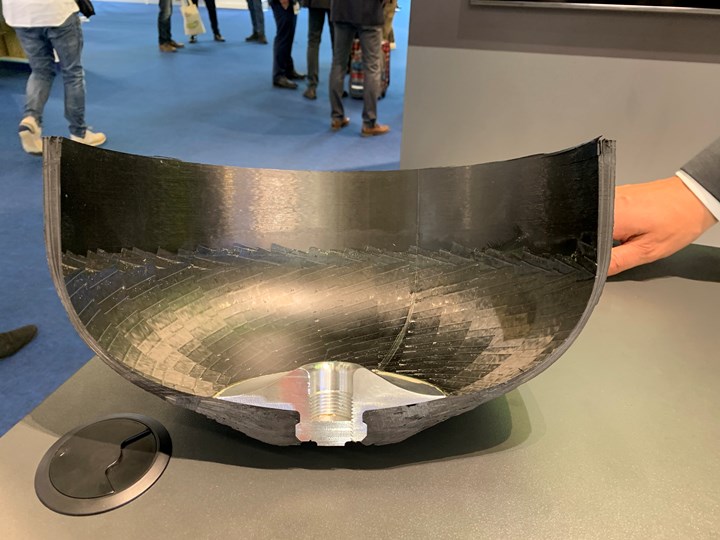

- Cutaway of Type IV compressed gas tank displayed by engineering firm CIKONI (Stuttgart, Germany) and fiber patch placement (FPP) technology supplier Cevotec (Unterhaching, Germany) in a project that has demonstrated at least 15% material savings by using FPP reinforcement on the tank boss dome to reduce redundant whole tank windings.

Related Content

Composite wrap system combats corrosion in industrial tank repair

A fiberglass and carbon fiber composite wrap system enabled an Australian nickel mine to quickly repair a stainless steel ammonium sulphate feed tank and protect against future corrosion.

Read MoreToray obtains ABS type approval for in-situ VARTM ship repairs

American Bureau of Shipping (ABS) certifies use of jointly developed CFRP repair technique on FPSO and FSO industrial systems, addressing traditional steel restoration challenges.

Read MoreHealable thermoset resin achieves ultra-fast composites repair

CAMX 2024: CompPair HealTech solutions give the ability to heal cracks and delaminations in a composite via local heating more than 60 times, available for a range of composite processes.

Read MoreFACC signs multiyear agreement with Pratt & Whitney for fan case MRO

FACC is growing its component repair services with the repair and overhaul of its customer’s composite PW800 turbofan engines.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More