Wind/Energy

GE to research AM for wind turbine blades

Twenty-five-month project to couple low-cost thermoplastic skin with AM for high-performance wind blade designs to be used on large rotors.

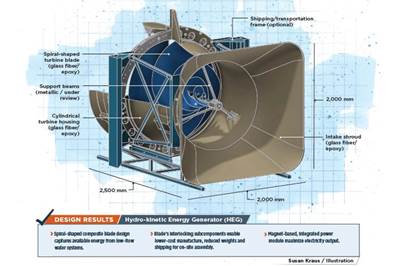

Read MoreHydroelectric turbine blade design propelled by composites

Glass fiber composites power the development of a modular, spiral-shaped hydroelectric micro turbine blade for low-cost, high-efficiency renewable energy generation.

Read MoreVestas unveils 15-MW offshore wind turbine with 115.5-meter-long blades

Industry’s largest rotor ups output by 65% versus 9.5 MW turbines, serial production for 2024.

Read MoreSicomin GreenPoxy resins contribute to first NFC wind turbine nacelle

Sicomin’s bio-based resins, intumescent FR gelcoats and UV-resistant clear coatings meet stringent requirements for Greenboats’ 7.3-meter natural fiber composite nacelle.

Read MoreBYK earns additive certification for rotor blade applications

The BYK-C 8001 coupling agent offers 60% improved mechanical strength, design freedom and universal application for glass fiber-reinforced epoxy resin systems.

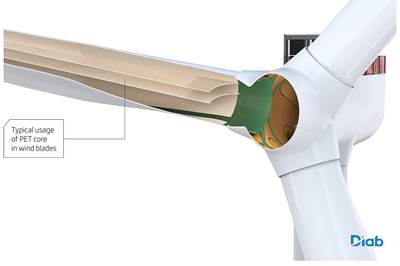

Read MoreSABIC LNP COLORCOMP compound enhances PET foam cores for wind turbine blades

Unfilled resin compounds decrease foam cell size and reduce resin uptake by the foam during manufacture for the creation of lighter, longer wind blades.

Read MoreGFRP trailing edge spoilers for rotor blades achieve 6% AEP increase

evoblade and Deutsche Windtechnik study confirms that the retrofittable Evoflap spoiler improves flow, offers load reduction and could potentially extend wind turbine service life.

Read MoreGurit reports Continued Operations net sales growth of 8.9% at constant exchange rates

Preliminary and unaudited net sales report for FY 2020 represent a 5.8% increase on a currency adjusted basis compared to FY 2019, with 16.2% growth at constant exchange rates over 2019 in Gurit’s composite materials business.

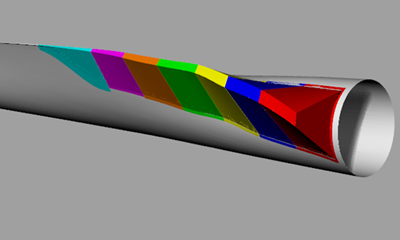

Read MoreBaker Hughes expands non-metallic products with new composite flexible pipe for onshore pipelines

New, 400,000-square-foot facility in Houston will increase composite pipe capacity by 3-4X for applications in multiple markets, part of strategic investment in non-metallics growth.

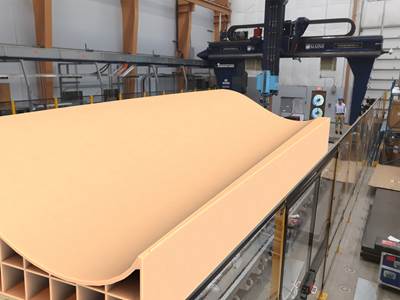

Read MoreUMaine awarded $2.8 million to accelerate AM wind blade development

Additive manufacturing with bio-based, 100% recyclable feedstocks reinforced with wood can reduce construction time by six months and cut costs by 25-50%

Read More

.jpg;maxWidth=300;quality=90)