SABIC LNP COLORCOMP compound enhances PET foam cores for wind turbine blades

Unfilled resin compounds decrease foam cell size and reduce resin uptake by the foam during manufacture for the creation of lighter, longer wind blades.

All photo credit: Diab Group

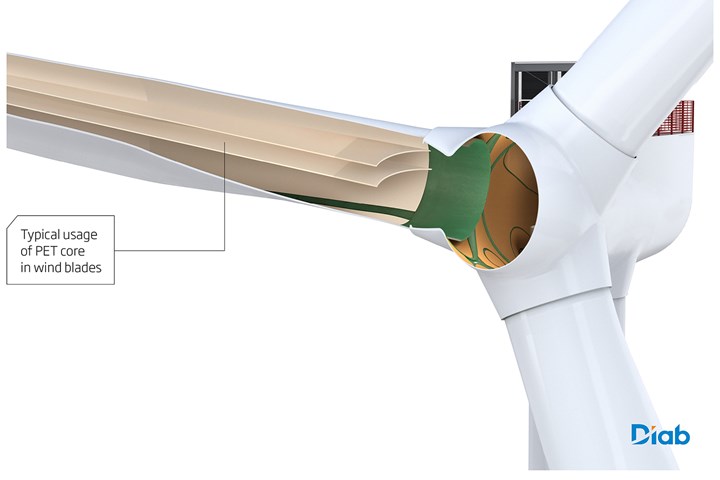

Diab Group (Helsingborg, Sweden), a sandwich composite solutions company, chose SABIC’s (Riyadh, Saudi Arabia) new LNP COLORCOMP compound to enhance the core material of wind turbine blades.

Said to reduce weight and improve mechanical properties of sandwich structures with polyethylene terephthalate (PET) foams, the compound incorporates SABIC’s nanotechnology by reducing the foam’s cell size by a factor of up to two, while maintaining the same density and decreasing the cell size dispersity. Selected over standard nucleators for production of Diab Group’s Divinycell PY PET foam core series, the LNP COLORCOMP compound’s improvements to core foam materials can help designers create new, longer blades that address increasingly stringent standards for precision, weight and consistent quality, and contribute to greater overall energy generation.

“Even though PET foam is relatively new to the wind turbine core materials market, as a thermoplastic it offers many advantages and is a good candidate for broader use in turbine blades,” says Magdalena Sandström, CTO Diab Group. “We are focused on optimizing the performance of our PET foams to drive industry adoption of a more sustainable solution. SABIC’s new LNP COLORCOMP compound, a material that provides increased control over cell nucleation and growth, is helping us achieve this goal. By leveraging this technology, we are developing innovative products that enable the implementation of larger and more-powerful blades.”

SABIC’s novel LNP COLORCOMP compound features a formulation that typically provides improved nucleation and helps to enhance the efficiency of the foaming process for a wide range of foam densities. By significantly decreasing foam cell size compared to standard nucleating agents such as talc and ensuring uniform cell size distribution, the SABIC product typically helps to reduce resin uptake by the foam during composite manufacture. Less resin contributes to a lighter-weight blade, the company adds.

SABIC wind turbines.

Another potential advantage of decreased cell size is the elimination of secondary foam processes or surface treatments that are used to close foam cells and decrease resin absorption. Further, smaller cell size and narrower size distribution can potentially deliver improvements in shear strength/strain properties that are not possible with conventional technologies or lower-density foams.

Beyond wind turbine blade core materials made with PET foams, SABIC’s LNP COLORCOMP compound typically offers the opportunity to enhance foams used in other applications, such as marine, construction and packaging components. SABIC’s LNP COLORCOMP compound is available globally.

“Our collaboration with Diab has opened exciting new opportunities to advance wind energy through higher-performing core materials that enable innovative composite designs,” says Luc Govaerts, director, Formulation & Application Development for SABIC’s Specialties Business. “Our novel compound based on nanotechnology, together with our formulation and material science expertise, help Diab to innovate, and will give wind turbine manufacturers access to core composite products that are strong, light and recyclable. Working with our customers, SABIC continues to do all we can to promote sustainability efforts across the spectrum, including supporting broader use of renewable energy sources.”

Related Content

-

NCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

-

Composites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

-

RTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.