Wind/Energy

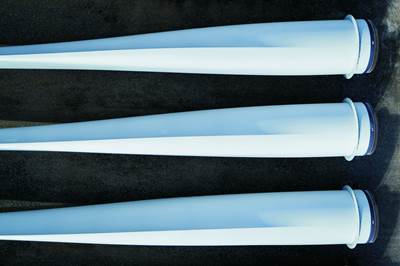

Noble Gas awarded $500K for conformable, compressed gas storage tanks

DOE MAKE IT prize supports U.S.-based manufacturing of clean energy technology components for a diverse range of market applications.

Read MoreKineco Exel Composites India to supply carbon fiber planks for wind

Multi-year agreement between the joint venture and a South Asian wind turbine manufacturer contributes to composite spar cap development.

Read MoreAcciona to build wind blade recycling plant in Spain by 2025

Waste2Fiber facility will use a proprietary thermal method to separate wind blade materials for reuse and will have a processing capacity of 6,000 tons of material/year.

Read MoreOcean Winds takes full ownership of SouthCoast Wind project

Madrid-based international company is focused on the joint procurement process for offshore wind in Connecticut, Rhode Island and Massachusetts.

Read MoreHengshen carbon fiber contributes to 143-meter-long MingYang wind blade

First MySE292 offshore wind blade from MingYang Group successfully rolled off the production line in February.

Read MoreUMaine researchers aim to recycle wind turbine blades as 3D printing material

With a DOE grant in hand, UMaine’s ASCC seeks to develop an approach to recycle shredded wind turbine blade material as a cost-effective reinforcement and filler for large-scale 3D printing.

Read MoreSwancor, Siemens Gamesa solidify recyclable wind blade partnership

Swancor will supply all recyclable resin to Siemens by 2026, contributing to RecylableBlade efforts.

Read MoreR&D projects, additively functionalized part demonstrate composites innovation

JEC World 2024: The DLR is presenting the EmpowerAX multi-curved shell demo part as a JEC Innovation Award winning innovation, in addition to results from other projects involving hydrogen tanks, wind and more.

WatchComposites expertise targets wind turbine nacelles

JEC World 2024: BlueWind is exhibiting at JEC World for the first time at the Brazil Pavilion, highlighting a novel nacelle technology.

Read MoreRepurposing wind blades as functional community art pieces

Ohio-based Canvus Inc. upcycles fiberglass wind blades, car tires and post-consumer plastics to create outdoor furniture that amplifies sustainability messages in community spaces.

Watch

.jpg;maxWidth=300;quality=90)