Noble Gas awarded $500K for conformable, compressed gas storage tanks

DOE MAKE IT prize supports U.S.-based manufacturing of clean energy technology components for a diverse range of market applications.

Noble Gas Systems (Novi, Mich., U.S.) has received a $500,000 prize in the U.S. Department of Energy’s (DOE) Manufacture of Advanced Key Energy Infrastructure Technologies (MAKE IT) initiative for its conformable, compress gas storage system. With this achievement, Noble Gas is eligible to participate in Phase 2 of the Facilities Track of the Prize, with the chance to be one of up to four companies receiving an additional $4.5 million.

“Our team is honored to receive this prize and equally eager to put it to use in advancing our patented conformable hydrogen gas tank technology and presence in Michigan,” says Chris Kondogiani, CEO of Noble Gas Systems. “We are aligned with the DOE on the importance of clean energy use and a domestic manufacturing base to strengthen our clean energy supply chains.”

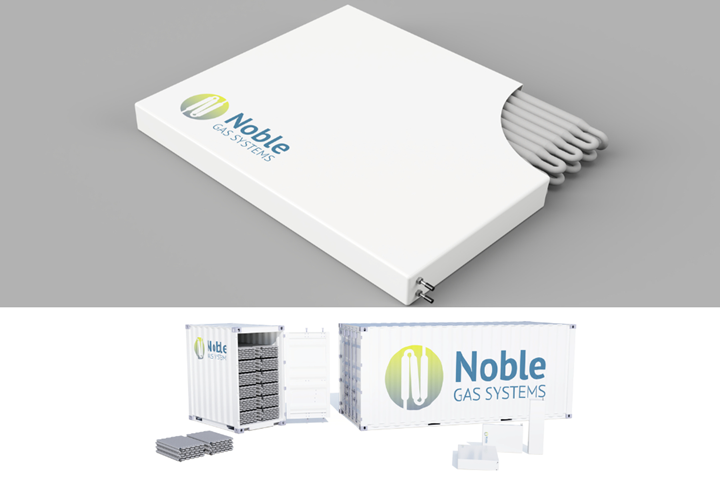

The Noble Gas high-pressure, lightweight storage and delivery system can accommodate common compressed gases, including natural gas, air, oxygen, hydrogen and nitrogen. It features a tank comprised of a polymer liner, woven reinforcement and protective outer shell. A safer alternative to other options, the Noble Gas system has passed regulatory design qualification tests for storing high-pressure compressed hydrogen gas and has a leak-before-burst failure mode to eliminate the opportunity for a catastrophic, instantaneous release of high-pressure gas. The company’s conformable hydrogen gas tank technology is currently being used by the U.S. military.

Designed with conformability in mind, Noble Gas’ storage system can be fabricated in a variety of shapes and sizes to be easily integrated into distinctive and existing product configurations. The tanks are lightweight and are being developed for working pressures between 350 and 700 bar. In addition to the transportation industry, Noble’s solution has applications in defense, aviation, marine and industrial gas industries.

“Being awarded a prize in Phase 1 is a tremendous accomplishment, but we now have our sights set on Phase 2,” adds Kondogiani. “If we are awarded a Phase 2 prize, we can accelerate our plans to create more than 50 direct green economy jobs in southeast Michigan.”

The MAKE IT Prize is part of the DOE’s American-Made program that fast-tracks innovation through prizes, training, teaming, as well as mentoring and connecting the nation’s entrepreneurs and innovators to U.S. national laboratories and the private sector. The prize makes approximately $30 million in funding available to create domestic manufacturing of critical clean energy technology components, moving manufacturing facilities from planning to shovel-ready, and enabling strategies for manufacturing activity in communities.

The prize was developed by the DOE Office of Technology Transitions (OTT) in partnership with the Offices of Clean Energy Demonstrations and Energy Efficiency and Renewable Energy, and is funded by the Bipartisan Infrastructure Law as part of the Technology Commercialization Fund (TCF).

Related Content

Composites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreUpdate: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreRead Next

Energy storage in multifunctional carbon fiber composites

A need for lightweight energy storage technology is fueling the development of carbon fiber composite materials for car batteries and other electronics.

Read MoreComposites end markets: Pressure vessels (2024)

The market for pressure vessels used to store zero-emission fuels is rapidly growing, with ongoing developments and commercialization of Type 3, 4 and 5 tanks.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More