Wind/Energy

Aditya Birla Chemicals acquires recyclable thermoset technology from Connora Technologies

The acquisition of Connora's Recyclamine technology enables end-of-life recyclability and zero-waste manufacturing to global epoxy customers.

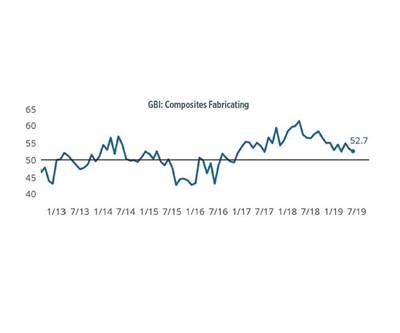

Read MoreEmployment activity leads expansion in business activity

The Composites Fabricating Index for June 2019 came in at 52.7, continuing its stretch of more than 30 months of expanding activity.

Read MoreDecommissioned wind turbine blades used for cement co-processing

An initiative to recycle wind turbine blades includes the use of recycled glass fiber composites for cement manufacturing, replacing raw material and saving energy.

Read MorePlastic Omnium opens hydrogen storage R&D centers in Belgium, China

The new centers will focus on the development of emissions control and fuel systems, including high-pressure hydrogen tanks and fuel cells.

Read MoreJoint project to advance wind turbine blade recycling

A group of European wind and chemical industry partners aims to broaden the range of recycling options for composite wind blades.

Read MoreInaugural National Composites Week to recognize, promote and celebrate composites manufacturing

From Aug. 26-30, 2019, composites manufacturers are encouraged to use social media, traditional media and in-person events to shine a light on the industry.

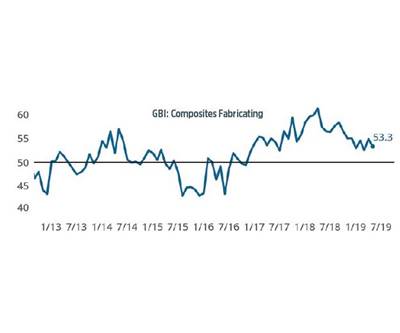

Read MoreIndex activity expands, led by production

The Composites Fabricating Index for May 2019 came in at 53.3, led higher by production activity.

Read MoreLightweight Manufacturing Centre opens in Scotland

The center, operated by the University of Strathclyde, is set up to develop lighter, more efficient components for automotive and aerospace companies.

Read MoreNatural fiber composites: What’s holding them back?

Natural fiber reinforcements have been available for some time, but factors such as compatibility with current processes and geographic availability continue to limit widespread use.

Read MoreNational Composites Centre purchases Coriolis C5 robotic gantry AFP

Developed for rate production of large, complex composite structures, C5 will be part of world’s most advanced, flexible dry-fiber deposition cell.

Read More