RTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

Evolving materials, manufacture for production-ready parts. ORPC’s RivGen hydrokinetic river turbines are designed to provide clean power to remote communities. In its latest design iteration, the struts (the yellow triangular structures) and foils (pictured in black, connected to the struts) are made from carbon- and glass fiber-reinforced polymer (CFRP and GFRP) dry braid and resin transfer molding (RTM) as a cost-effective, faster alternative to prepreg and autoclave cure. Photo Credit: ORPC, via Hawthorn Composites

Ocean Renewable Power Co. (ORPC, Portland, Maine, U.S.) develops hydroelectric energy solutions compatible with rivers and ocean tides. Founded in 2004, the company installed its first commercial RivGen Power System in 2019 in the village of Igiugig, Alaska. The RivGen system, rated at a power output of 40 kilowatts at 2.25 meters per second of river flow, is designed as an electric power solution for remote communities. Integrated with a community’s main grid, the RivGen system acts as reliable primary or backup power source and has the potential to reduce reliance on fossil fuel-based electricity.

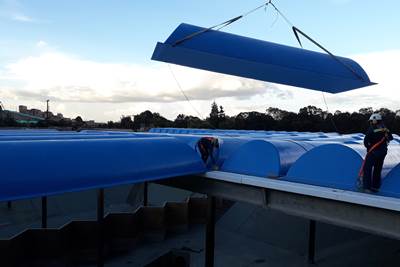

The RivGen system itself is modular, designed for easy transport and assembly, and when operational, is submerged completely underwater. Water flows perpendicular to the system’s curved foils, which are suspended by a series of triangular struts connected through their center to a steel shaft. This assembly sits on a deck between two long, blue modules reminiscent of catamaran hulls. The subsequent rotation of the shaft turns an underwater generator located on the submerged structure. This generator converts the rotational power into electricity, which is transmitted to shore via a submerged power cable.

Ryan Tyler, vice president of products and services at ORPC, explains that the first RivGen prototype was built in 2012, “and then for what we consider our current turbine iteration, that work really started after about 2015.”

As ORPC moved toward its production model, the company began to reevaluate the manufacturing methods and materials it had been using to build its prototypes. By the end of 2021, this included reevaluating how it built the system’s foils and struts.

The 18-foot-long foils in particular posed a design challenge. Tyler explains, “The RivGen gets its performance based on the hydrodynamic properties of the foils — they’re sort of like wings on an airplane.” The earliest subscale foil prototypes were simple in shape, and made from plastic or metal. “For the full-sized foils, the shape is a bit complex, and they’re also twisted, and they run 18 feet long. All combined, that can create some pretty big challenges, especially for some more traditional types of manufacturing. That’s one of the reasons that composites are appealing for us, the complex geometry.”

Ultimately, ORPC turned to composites for both the complex foils and the struts that attach them to the steel shaft. “Composite design is pretty complex,” Tyler adds. “Something we’ve certainly spent a lot of time on, especially over the last 5 or 6 years, is trying to improve our own internal capabilities in that regard.”

Matthew Barrington, mechanical engineer at ORPC, explains that the original composite design for the foils and struts was made from prepreg manufactured via hand layup and autoclave cure. However, “The materials are pretty expensive, and the process is time-consuming with a lot of man-hours,” he says. “Two factors to look at when you’re making foils are the price of the material, and then also the price of the finished part. And if there’s a big difference between those two, then maybe the process is too complicated or taking too many man-hours.”

The company decided to look into alternative composite options. In early 2022, ORPC put out a request for quotes and connected with Hawthorn Composites (Miamisburg, Ohio, U.S., a division of Spintech Holdings Inc.), a fabricator that specializes in use of dry fiber and resin transfer molding (RTM), primarily for defense aircraft components. Craig Jennings, CEO of Hawthorn Composites, explains that the company submitted a proposal for making the foils and struts faster and cheaper, using RTM and dry braided preforms provided by Hawthorn’s frequent supplier partner A&P Technology (Cincinnati, Ohio, U.S.).

Redesigning for dry braid, RTM

Over the next few months, Hawthorn and A&P Technology worked with ORPC on design iterations for the struts and foils, starting from test coupons.

The top goals for the parts, Barrington says, were durability, — the RivGen system has a design life of 25 years — stiffness and fatigue. The foils in particular “go through millions of cycles, almost into the billions, over their life, and need to be able to flex back and forth a lot of times, and they need to be stiff enough to keep their shape through pretty high loading,” he says. ORPC also wanted the geometry of the final part designs to match the original designs as closely as possible.

Ready for assembly. Hawthorn Composites manufactures foils (top, carbon fiber/epoxy) and struts (bottom, fiberglass/epoxy) for assembly into the RivGen system. Photo Credit: CW

A&P Technology provided material properties, which ORPC compared against the original prepreg properties used to design the prototype parts. ORPC then had flat coupon test panels made with several types of A&P braided material, which were tested at ORPC’s lab in Brunswick, Maine. After several rounds of testing, “we plugged the material data into our 3D models, and were then able to simulate the Hawthorn foils, and define the layup and number of plies,” Barrington explains. ANSA (Beta CAE, Root, Switzerland) and SolidWorks (Dassault Systèmes, Vélizy-Villacoublay, France) software were used for finite element analysis (FEA) modeling.

Next, Hawthorn began building test articles to help verify and optimize the design. Jennings notes that the foils posed more challenges in the design process than the relatively simple struts. “They have a thick, curved leading edge, and carry much more load over time,” he says. Due to the shape, there was more potential for wrinkling during layup or infusion, which Hawthorn had to figure out how to avoid. The foils are also hollow to reduce weight, necessitating each 18-foot part to be manufactured in two halves filled with foam in the middle.

“It was a planned learning process that took several iterations, and then once we tuned it, moved along pretty well,” Tyler says. Visual and ultrasonic testing were used on the earliest foil iterations, as well as samplings of foils that were built along the way.

Materials: Carbon fiber foils, fiberglass struts

After this iterative design and testing process, the foils Hawthorn builds today are made from carbon fiber composites and the struts from fiberglass. “Fiberglass is ideal because it’s less expensive, but for the foils, carbon fiber is the only material available today that can allow us to make our foils as small as possible and as hydrodynamically efficient as they are,” Barrington says. “You could use fiberglass but then you’d have to use a bigger foil, which would negatively impact the performance. Fiberglass works well for the struts because they don’t have as much loading and they can be thicker.”

Carbon and fiberglass braided fabrics. To manufacture the struts and foils, first, Hawthorn Composites cuts and kits fabrics at its Miamisburg, Ohio, facility. Photo Credit: CW

More specifically, the foils are made from a combination of custom-made, dry carbon fiber fabrics from A&P Technology, including unidirectional (UD) and braided fabrics, in ±45°, 0° and ±60° orientations, infused with industrial-grade Hexion Epon 862 epoxy supplied by Westlake (Stafford, Texas, U.S.). The foils are laid up with 17 plies per half, with a vacuum bag in the middle, connected at the parting line by a staggered lap joint. Tim Holtz, business development manager at Hawthorn Composites, notes that some of the plies include off-axis fiberglass tows to help facilitate resin infusion. Each strut is made from 36 plies of QISO-braided fiberglass fabric infused with Westlake epoxy.

Jennings explains that custom “thick-ply” fabrics from A&P Technology were used for both the foils and struts. The relative thickness means that fewer overall plies need to be laid up per part, “streamlining the layup process and enabling quicker progression of the parts throughout the manufacturing process. The improved build time facilitates faster deployment of ORPC’s RivGen technology in the field,” he says.

Process: RTM

CW had the chance to tour Hawthorn’s Miamisburg, Ohio facility while several ORPC struts and foils were being manufactured. According to Holtz, along with reducing material costs by switching from prepreg to dry fiber and liquid resin, the goal was to significantly cut down manufacturing time.

The process begins with cutting and kitting the fabrics needed for each part. Hawthorn expanded its Autometrix (Grass Valley, Calif., U.S.) cutting table to 24 × 6 feet in order to meet the requirements of the 18-foot foils.

Next, technicians lay up the kitted fabrics onto matched metal molds, which are designed by Hawthorn and manufactured by partners. Layup of the solid struts is relatively straightforward, Holtz explains, while the foils are more complex. Each hollow foil half is carefully laid up with a vacuum bag inserted inside, to be replaced with Sicomin (Châteauneuf les Martigues, France) foam after infusion.

After layup is completed and molds are closed, the parts are transferred to Hawthorn’s oven room, which houses six industrial ovens of various sizes, the largest being 13 × 13 × 40 feet. RTM infusion of the epoxy is performed in the oven for more than 2 hours, with heat and vacuum applied.

Once parts are infused and cooled, they are extracted from the molds and go through several final finishing steps. Foam is inserted into the hollow foils.

Strut layup. The struts, which do not need to be as lightweight as the foils, are laid up primarily with braided glass fiber fabric (top image). After molds close, both the struts and foils are infused with epoxy under heat and vacuum bag in an industrial oven (bottom). Photo Credit: Hawthorn Composites

Ultimately, the foils will be attached to the struts during assembly, and the struts to the rest of the RivGen system. To ease this process, 45 holes need to be drilled per strut, and six holes are drilled into each foil, which are then fitted with fiberglass composite bushings where the foil will be attached to metal plates.

For the first iterations, Hawthorn drilled all of these holes by hand, which takes up to 8 hours per strut. To move into production of the parts, Hawthorn acquired a ShopBot Tools (Durham, N.C., U.S.) router specifically to speed this process. The ShopBot router can be programmed by Hawthorn’s technicians in about 20 minutes, and then can operate hands-free, taking 2 hours or less per part.

Once all steps are complete, the finished foils and struts are sent to ORPC in Maine or Quebec for assembly with the rest of the RivGen system.

Finishing touches. To speed up finishing of the struts, an automated, hands-free ShopBot router was acquired by Hawthorn to drill holes into each part (top image). Holes are drilled into the foils by hand due to their size, and painted to finish (bottom). Photo Credit: CW (top image), Hawthorn Composites (bottom)

According to Jennings, compared to the previous hand-laid prepreg design, the new struts reduced manufacturing costs by 20%, and the revised foils reduced costs by 35% and cycle time by 70%. Holtz says one of the largest time-saving factors is during the layup process — layup of thicker, dry braided fabrics is much quicker than the thinner prepregs previously used. Much of the cost savings is due to use of lower cost raw materials and the ability with braid to use fewer overall layers than are needed for a prepreg version.

“Hawthorn uses relatively less expensive raw materials — dry fiber and liquid resin — and higher quality tooling to make the layup process quicker,” Tyler affirms. “This type of process requires larger overhead costs for the tooling, but in the end you still get more cost-effective parts that are made faster, with the same quality as prepreg parts because of their tooling and internal vacuum process.”

Expanding production of RivGen systems, developing tidal systems

Since 2022, Hawthorn has delivered about six shipsets of six foils and six struts each. ORPC has installed multiple units, some of which have Hawthorn foils and struts on them, in Alaska and Maine in the U.S., and in Manitoba, Canada. The first units in South America shipped to Chile in December 2023.

What’s next for ORPC? “A big focus is continuing to expand the market for the RivGen and getting more units installed,” Tyler says. “We’ll also of course continue efforts to reduce costs and improve performance.” This includes R&D initiatives such as the ongoing Crimson project, which is looking at the use of recycled materials within the RivGen design and manufacturing process.

Longer-term, the company plans to roll out two larger tidal power systems, called TidGen. The company completed testing of a single-turbine tidal device in 2023 at its Cobscook, Maine test site, and plans to validate a full-size, four-turbine system in 2024 to 2025. “The RivGen is targeted towards remote communities [and installation in rivers], whereas this tidal unit is geared toward remote, coastal communities as well as grid-connected tidal applications,” Tyler says.

The TidGen system “is essentially two RivGens connected together, using the same turbine design but doubled,” Tyler explains. As expected, the power output is also therefore double, roughly 80 kilowatts at 2.25 meters per second of water flow. As of the end of 2023, the design has been through initial small-scale testing and the full-scale version is in the final design stages.

The company is also in early stages of developing a larger, megawatt-scale system that, Tyler notes, will likely require very different foils and potentially a different manufacturing process. “One of the benefits of our systems is that they are able to share components across the systems, including the composites that make up both the RivGen and TidGen systems,” he adds.

Related Content

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MorePultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreThe next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreRead Next

Braided preforms and resin infusion for next-generation aerocomposites

Spintech shows significant cost and labor savings using its Smart Tooling, dry fiber preforms and RTM/VARTM technology on aircraft wing and inlet duct demonstrators.

Read MoreFoiling motoryacht impresses in carbon fiber/epoxy

A project is underway to build a faster, lighter, hybrid-electric motorboat with foils and hull fabricated from carbon fiber and epoxy.

Read MoreLarge composite covers protect a lot of water

A massive concrete water storage facility in Bogotá, Colombia, gets a much-needed makeover with the resin transfer molding of 840 large composite domes that keep the water potable.

Read More

.jpg;width=70;height=70;mode=crop)