Modular, upgradeable, automated composites manufacturing equipment

CAMX 2024: Mikrosam highlights its filament winding automation, AFP and ATL, modular prepreg slitting and rewinding machine, and towpreg production lines for productivity and reduced costs.

Share

Mikrosam (Prilep, Macedonia) is a producer of equipment and automation for several composites manufacturing processes, including: filament winding automation, automated fiber placement (AFP) and automated tape laying (ATL), and in-house modular prepreg slitting systems. With a strong focus on innovation and customization, the company provides customized solutions to meet the needs of its clients, aiming to enhance productivity and reduce production costs.

Mikrosam produces automated lines for composite pressure vessels and high-value products. These lines ensure a lower total cost of ownership, high availability and productivity, with increased throughput and reduced cost per part:

- Multi-spindle high-performance automation

- Patented automatic cut and restart system, exchangeable resin bath

- TCON: Top-level automation and manufacturing historian with SCADA integration.

Mikrosam also introduces a gantry-based multi-axis handling system for composite parts. Gantry handling is crucial in multi-spindle winding, especially for handling tanks and parts exceeding 1,500 L, where robotic handling cannot be used. It is ideal for heavy loads, long travel distances or small workspaces.

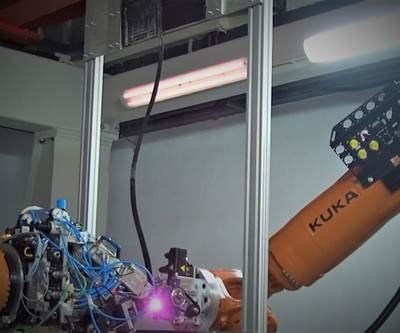

Mikrosam further highlights its AFP and ATL solutions, designed for flexibility, ease of use and scale, which enable users to start with an initial setup that can support business growth. Solutions include multi-material AFP and ATL heads, technology with a head exchange system and the capability for thermoplastics.

Mikrosam offers scalable machines for slitting composite prepregs to different widths and form factors, combined with an inspection system for traceability and detecting errors. The return on investment (ROI) with Mikrosam’s slitting machines is said to be 12 to 18 months. Further improvements and modularity of the system make it well suited for the growing use of slit prepregs.

The company’s customized solution for in-house towpreg production is said to reduce the total production cost, resolve many logistics-related questions and provide higher process and material quality control. The company says that users can expect accurate calibration of towpreg resin content, cost savings and the ability to produce a range of towpreg widths.

Related Content

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Related Content

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreRead Next

Filament winders specialized for composites hydrogen vessel production

JEC World 2024: A pressure vessel for HydroExceed manufactured via a recently delivered multi-spindle filament winder displays Mikrosam’s expertise in filament winding equipment.

Read MoreMikrosam automates thermoplastic composites with toolless multi-robot placement system

Mikrosam (Prilep, Macedonia) introduces an automated process for fabrication of thermoplastic composites without the use of molds or tools.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More