Must-have capabilities in a large-format additive manufacturing machine

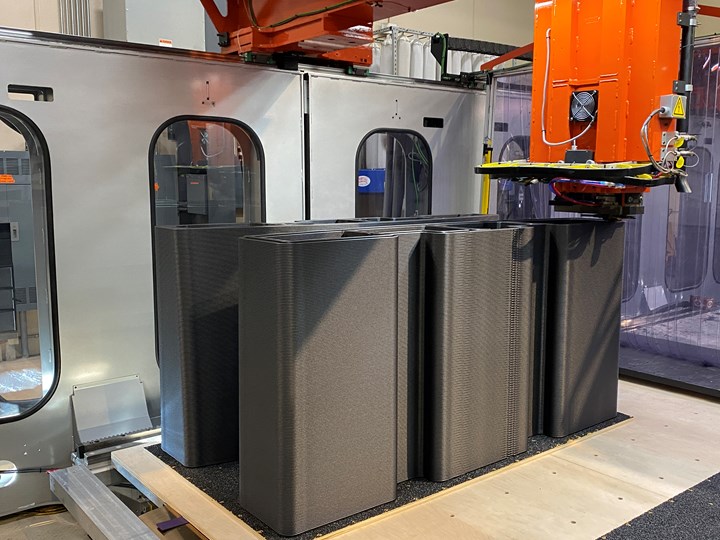

Thermwood’s Large-Scale Additive Manufacturing (LSAM) system comes equipped with many features that make fabrication of large fiber-reinforced polymer parts and structures fast, efficient and accurate.

Share

In this Digital Demo, CNC specialist Thermwood outlines 21 features of its Large-Scale Additive Manufacturing (LSAM) machine that help make it a good solution for the production of fiber-reinforced thermoplastic molds, tools, patterns, fixtures and finished parts.

The Digital Demo introduces and explains each feature, including, for example, the ability to print and trim on the same machine, Thermwood’s patented polymer pump and its compression wheel technology. Thermwood has grown to become the top supplier of large-format FDM systems in part because of the depth, breadth, capabilities of the LSAM line. This makes it easy to find a machine that aligns with your manufacturing needs. To learn more about the features and functions of the Thermwood LSAM line, watch this Digital Demo and then visit Thermwood at…

For more information on this and other Thermwood products, follow them online on Facebook, Twitter and LinkedIn.