Share

Proterra Catalyst battery-electric buses already have logged more than 4 million miles of zero-emission and — no small benefit — foul-fume-free service in public and commercial transit duty. Behind that green success is a structural design by Proterra Inc. (Burlinghame, CA, US) with TPI Composites Inc. (Warren, RI, US), in which all loads are supported solely by a monocoque composite structure. Minus the conventional steel frame, the buses are lightweight enough to offer operators a nominal range of 350 miles on a single charge.

Composites technology enables performance goals

“A transit bus can log hundreds of miles each day for 12 years up to 20 years, so we needed high strength, low weight and durability,” says Joshua Stewart, Proterra director of customer engineering. “The composites technology enables those goals.”

Catalyst boasts an acceleration from 0 to 20 mph in 4.5 seconds (an important asset for a bus merging into traffic); a curb weight of 26,000-33,000 lb (11,793-14,969 kg), claimed to be the lightest in its class; and a climb gradeability of 15.5%, or 8°. (Gradeability refers to the percent of slope, or the steepest incline, the vehicle can climb from a standing start.) Further, the composites design offers unmatched corrosion resistance.

Stewart notes that another substantial benefit of composites is safety in a collision. Automotive composite pioneer Gary Lownsdale, now owner of consulting company TransTech International Inc. (Loudon, TN, US), tells us how it works: “Though the damage mechanisms comparing metals and composites are complex, in general, we can say that metals deform in a linear fashion and pass the energy wave through to the next structure, causing serial failure (breakage). Composites, on the other hand, deform in a nonlinear fashion.” Advantageously, they can be designed to deform predictably and then fail in a specific mode, which enables the designer to tailor the energy absorption via selective use of the matrix. Lowsdale suggests one way to look at this is to compare force vs. deflection curves for metals and composites. With metals, there is a straight line (linear curve) until the material’s ultimate tensile strength or yield strength is reached. Then there is a sharp drop off as the material fails and energy is released. This curve is roughly the same at both high and low strain rates. “With composites,” he notes, “the material’s curve continues to rise well above that for metals and then gradually tapers off as failure begins and energy is released.” The area under each curve is the amount of energy that can be absorbed in a crash. And if one is laid over the other, the composite’s curve is much larger, indicating that the composite can absorb much more energy in a crash and that it can do this at much higher strains and at much faster rates. “The ability to absorb more energy at a given force and over a given distance,” Lownsdale concludes, “is a big advantage of composites.”

Manufactured by low-emission SCRIMP

To establish material and process parameters, the design team conducted extensive finite element analysis (FEA), using ANSYS (Canonsburg, PA, US) simulation software for the body structure, in addition to sample validation testing. E-glass fibers in stitched noncrimp fabric (NCF) and unidirectional (UD) carbon fiber NCF materials, in a vinyl ester resin closed infusion molding process, were selected to best meet mechanical requirements and environmental conditions, such as weather and ultraviolet (UV) light.

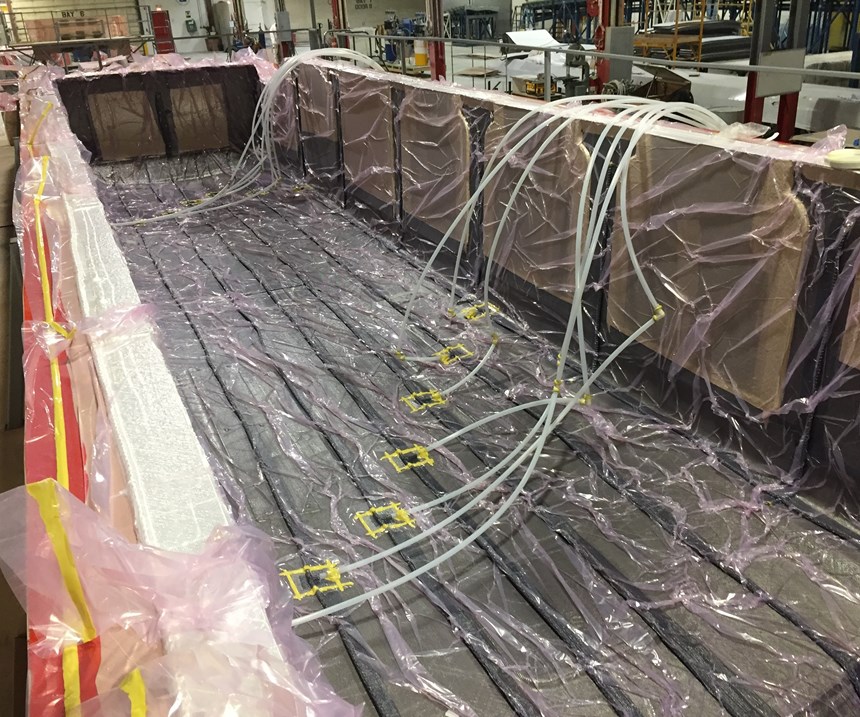

TPI manufactures the bus bodies using the Seeman Composites Resin Infusion Molding Process (SCRIMP), a customized upgrade of vacuum-assisted resin infusion developed for making high-quality, repeatable composite parts with nearly zero VOC emissions. TPI engineering manager Brian Lucchesi says TPI has been producing large structural composite components with this method for more than 25 years. He notes that tests have verified its workplace safety, noting that “VOC emissions of 0.2 to 0.6% from TPI’s SCRIMP process have been observed and confirmed by the Rhode Island Department of Environmental Management.”

TPI also manufactures all its own tooling, including multi-piece composite molds supported by a structural steel framework.

The bus is built in four basic sections using the same materials and manufacturing process, in a mix of solid laminates and sandwich structures with a balsa wood core. The bus body consists of the upper body from the roof down to the lower edge of the windows, which includes the entire windshield and rear window geometries; and the lower body from the lower window line down to the floor, which includes all structural chassis geometries for vehicle subsystem attachments (see Fig. 2).

The roof consists of one upper fiberglass structural sandwich molding down to the window line, and another for the lower (ceiling) geometry.

Manufacture generally proceeds as follows: First down in the mold is a gel-coat layer to produce a smooth, appealing exterior. Dry fabrics are then manually arranged in the mold: Triaxial (0°, ±45°) fiberglass reinforcements provide longitudinal and torsional stiffness for the main global plies. Unidirectional (UD) carbon fiber NCF strengthens window frames and the A-pillars that attach the roofline to the lower body and surround the windshield. Carbon fiber, with its high stiffness properties, reduces window and door opening displacements, thereby minimizing the kind of distortion that could lead to fracturing of the glass. Quadriaxial (0°, 90°, ±45°) quasi-isotropic fiberglass material is used where high strength and stiffness are especially critical, notably where suspension components interface, where mirrors and lights and other exterior elements are connected, and in areas subject to high compression — for example, where airbags interface with the body and at the major drive-axle connection.

The layup is vacuum bagged, infused with a catalyzed vinyl ester resin system and cured at room temperature.

Interior components and attachments

Interior composite panels in wheel well boxes (which provide storage areas for electronic equipment), structural composite floor components, metallic plates and inserts, and other interior components are bonded into roof and body primary sub-assemblies before they are bonded together.

Bus doors are still aluminum; however, some of Proterra’s suppliers have composites versions in the works, Stewart says, adding, “we hope to be the first to have them.”

Doors and other interior components are attached using Proterra’s proprietary composite mounting brackets, adding an extra strength-to-weight advantage. The brackets are attached either by molding stainless steel inserts into the laminate, or by bonding.

For attaching the doors, hat brackets are bonded onto the adjacent body, with stud plates embedded into the brackets. The door structure is mounted to the stud plates. “This is not only convenient, it is a dimensional aid for correct door positioning every time; there’s no guesswork in the install,” Stewart says.

Bumpers currently are also primarily aluminum structures with reaction injection molded (RIM) plastic covers, he adds. Bumpers are attached to the body by bolted hat brackets.

Methyl methacrylate (MMA) adhesive is used for all bonding processes. The cured sections of the roof and body are adhesively bonded together to complete those sub-assemblies and the sub-assemblies are then adhesively joined for a permanent bond to create the finished product.

Better and less expensive than

More than 140 of the buses, a mix of Catalyst FC, XR and E2 35- and 40-ft models, were on the road by year-end 2017 in communities across the US from Washington state to Florida. That number is expected to double in 2018. “We’re expanding our production capabilities to meet existing sales and projected demand,” says Stewart.

In addition to the emissions advantages, and the high mileage between charges afforded by the lightweight composite bus body, the Proterra/TPI design also reaps financial benefits. Factoring in fuel and maintenance cost savings over the lifetime of a vehicle, Proterra calculates its buses save transit agencies US$448,000 during a 12-year service life compared to diesel alternatives (about $2.36/mile compared to US$2.83/mile).

Related Content

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreJEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreWatch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More