Photo Credit: SpaceX

On April 12, 1961, Soviet Cosmonaut Yuri Gagarin was launched aboard a rocket in Russia and became the first human to reach space. He orbited the earth in a flight that lasted 108 minutes. Several weeks later, on May 5, astronaut Alan Shepard became the first American to reach space in a 15-minute flight aboard a Mercury capsule. Although the “space race” between the USSR and the U.S. had technically begun a few years earlier, the stakes suddenly became much higher with manned space flight.

Eight years later, the U.S. Apollo program delivered astronauts to the surface of the moon and returned them to Earth safely, arguably making the U.S. the “winner” of this first space race. A series of lunar missions followed soon after, prior to the Apollo program’s completion in 1972. Since then, the focus on space has centered around satellite, telescope and probe launches, as well as orbiting scientific habitats, including Skylab, Mir and the International Space Station (ISS). Similarly, the Space Shuttle program served to support many cargo deployments and the establishment of the ISS. Composites have played a leading role in the structures of space vehicles for close to 50 years.

Is space tourism a viable business? Can the technology, including the use of composites, get us closer to successfully returning to the moon and beyond?

On July 11 of this year, a Virgin Galactic (Mojave, Calif., U.S.) White Knight Two composites-intensive airplane ferried the VSS Unity SpaceShipTwo to an altitude of 45,000 feet, where the smaller vehicle’s rockets ignited and powered the craft to an altitude 53.5 miles above sea level. The crew of four, which included Virgin Galactic founder Sir Richard Branson and three other employees, experienced several minutes of weightlessness before pilots successfully returned the spacecraft to the launch site in the New Mexico desert.

Nine days later, less than 250 miles away in west Texas, a Blue Origin (Kent, Wash., U.S.) New Shepard reusable rocket, named after Alan Shepard, carried a capsule with four humans to an altitude 66.5 miles above sea level where they also experienced the weightlessness of space. The 11-minute mission, which was fully autonomous and without pilots, was the first crewed mission for the rocket. The passengers included Blue Origin (and Amazon) founder Jeff Bezos, his brother Mark, Oliver Daemon from the Netherlands (at 18, the youngest person to go to space) and Mary Wallace “Wally” Funk, who at 82, is considered the oldest person to travel to space, surpassing John Glenn, who was 77 when he flew on the Space Shuttle in 1988. Funk has a long lineage in aviation and the space program going back to the Mercury years, fulfilling a lifelong dream to be an astronaut.

Both events in July drew a lot of attention and press coverage (aided by remote broadcasts transmitted live by satellite, thanks to space technology), but they certainly beg the question: Are these endeavors just the pursuit of two billionaires with big egos, or are Virgin Galactic and Blue Origin part of a new space race bringing the experience of flying above the magical Kármán Line — the internationally recognized boundary of space — to a multitude of people? And are their achievements significant, given that the USSR and NASA attained at least as much in 1961? Branson and Bezos both are pursuing a strategy of selling seats on future missions to make space more accessible, although at prices seemingly affordable only to millionaires and fellow billionaires. While Virgin Galactic remains focused on space tourism, Blue Origin is also developing the much larger New Glenn rocket (named for NASA astronaut John Glenn) for delivering payloads to near-Earth and geosynchronous orbit.

Meanwhile, fellow billionaire Elon Musk’s space ambitions continue apace at SpaceX. Following the May 2020 launch for NASA of the Crew Dragon above a reusable Falcon 9 rocket, SpaceX carried NASA astronauts for extended missions to the ISS in November 2020 and April 2021, and is scheduled to do so again this October. The Dragon platform has also made at least 20 cargo trips over several years. Musk has made it clear that the goal for SpaceX is to deliver humans and supplies to the moon, and eventually to Mars.

These privately developed spacecraft benefit greatly from decades of publicly funded space initiatives, and the combination of computing power and advanced controls are reducing per-launch costs thanks to the use of reusable hardware. Is space tourism a viable business? I’m not quite sure that business model is sustainable at current price points. Can the technology, including the use of composites, get us closer to successfully returning to the moon and beyond? Of that prospect I am more positive, especially if the incentives between government objectives and the private enterprises can be well aligned to serve the needs of society and investors.

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MoreRead Next

Virgin Orbit automates composites machining processes for LauncherOne rockets

Part of the company’s larger strategy for reducing cycle times and labor costs on its composite-intensive rockets, a customized machine center from Multiax America solves composite machining challenges.

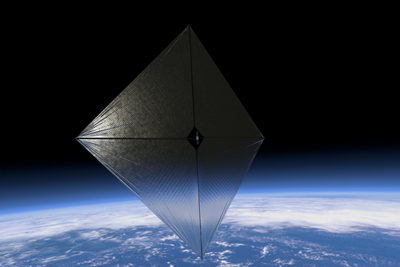

Read MoreNASA develops advanced composite solar sail system

The ACS3 mission expects to demonstrate the successful deployment of the composite boom solar sail in low-Earth orbit to guide the design of future, larger-scale composite solar sail systems.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More