A return to JEC World

CW editor-in-chief Scott Francis reflects on the ways in which the composites industry has changed and also stayed the same based on observations from this year’s JEC World.

Source | CW

It’s been five years since I last attended JEC, a result impacted by the infamous COVID-19 pandemic and a career path change with CW’s parent company, Gardner Business Media, around the same time. It’s true that everyone has their own pandemic story: mine began when I stepped off the plane in Paris in 2020 and received a text that JEC had been canceled. After that, the trade show didn’t return until 2022, and the years leading up to it held new responsibilities, learning about other areas of manufacturing and a hope to one day return to the CW brand.

Things came full circle for me at this year’s JEC World. Aside from just being excited to be back, the time away has provided an interesting perspective on how the industry has evolved during the last few years. For starters, many of the trends that seemed to be driving the composites industry in 2020 are still being talked about. After all, for so many of the markets that composites touch, the road to qualification takes a great deal of time and countless iterations.

Take trends in the aerospace industry, for example. While the world continues to hope for the announcement of a new commercial aircraft program, both Airbus and Boeing seem to be in a bit of a holding pattern. Setbacks in aircraft production due to COVID-19 and issues with the Boeing 737 Max program have stalled the declaration of a much-anticipated new mid-market airplane (NMA) program. Nevertheless, research continues into these areas with Tier suppliers poised for the next big program when it happens.

Research into the use of thermoplastics in aircraft production continues to be a big topic of discussion. Five years ago, conversations primarily surrounded such programs as the Airbus Wing of Tomorrow and the Multifunctional Fuselage Demonstrator (MFFD). Those projects are ongoing today. There were at least five demonstrators exploring the use of thermoplastic composites in aerospace structures on display this year at JEC World.

Arguably one of the largest areas of innovation in aerospace are advanced air mobility solutions. Numerous prototypes for flying cars, air taxis and eVTOLs are driving research into lightweight materials. The use of adhesives and bonding technologies, including ultrasonic and induction welding, to provide uniform stress distribution and to eliminate the need for fasteners, are playing an important role in overall weight savings, and could influence the trends we see in other aircraft development.

In the energy sector, pressure vessels and hydrogen storage solutions continue to be a focus and show promise as the next big growth area in the composites industry. Meanwhile, the ramifications of what high-rate production for the hydrogen market will mean for the carbon fiber supply chain was a topic of speculation.

In addition, sustainability solutions ranging from the use of recycled, reclaimed and bio-based materials to process efficiencies and energy saving technologies continue to be explored in all sectors. With the 2024 Summer Olympics in Paris looming large, the trade show floor featured many examples of the use of recycled or reclaimed materials in the sporting goods and marine sectors. And while sustainability was indeed a large focus at this year’s JEC World, the messaging felt a bit more grounded, reflecting a general expectation from OEMs and consumers that sustainable materials, technologies and processes and life cycle analysis (LCA) are an integral aspect of composite part design and production.

It was good to be back at JEC World. While there were no earth-shattering announcements this year, it was exciting to see how far some of the familiar programs and trends have progressed. It was also good to see the work being done, innovations being developed and the continued advancement in our industry.

Related Content

Revisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

Read MoreAs 2023 begins, a look back at trending CW topics in 2022

With 2022 now behind us, CW’s editor-in-chief Jeff Sloan takes a look at the CW stories last year that received the most reader attention.

Read MoreUp, not out: The next chapter of CompositesWorld

I have been editor-in-chief of CompositesWorld for 17 years, which translates into a lot of editorials. This will be my last as I become publisher of CW. We welcome Scott Francis back to the brand to take my place.

Read MoreThe real value of CompositesWorld

Will CW editor-in-chief Jeff Sloan soon be replaced by ChatGPT? Probably not before he retires, but it’s fun to consider the possibility.

Read MoreRead Next

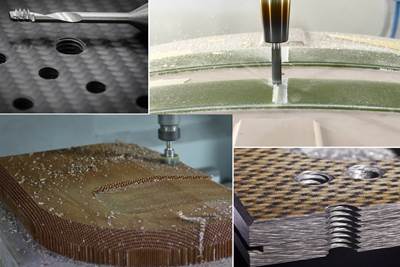

Optimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MoreWho's ready for the Olympics?

With the 2024 Summer Olympics in Paris, this year’s JEC World is bound to be abuzz with talk of this year’s event — from the use of composites in sporting equipment to the roles they play in AAM.

Read MoreJEC announces three JEC Startup Booster 2024 winners

Out of the 20 startups, Zila BioWorks, TechnoCarbon Technologies and BioHalo were recognized for broader collaboration opportunities.

Read More