Abrasive machining methods for composites

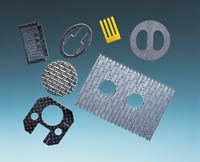

Cutting, routing and drilling are important post-processing steps for cured composite parts.

Engineers devote considerable time and resources to proper composite design, material selection and fabrication, to achieve a perfect, finished product out of the mold. But in most cases the demolded part has to be trimmed, cut or joined to another composite or metallic part, presenting the manufacturer with a different set of challenges. Although composite parts can be designed with integral connectors, more often than not, mechanical fasteners are selected for highly stressed connections or joints that require periodic disassembly. In addition to flash trimming and part routing for smooth edges, a single aircraft often requires many thousands of drilled holes in various composite parts.

"Holes serve as areas for stress concentration and can have a detrimental effect on the strength, stiffness and reliability of the composite by disrupting the fiber load path," says Lynn Klett of the Metals and Ceramics division at Oak Ridge National Laboratory (Oak Ridge, Tenn., U.S.A.), who is currently studying the effects of different machining methods on composites. "The method for making the hole can itself damage the composite."

By far, the most common methods used for machining composites are abrasive, as opposed to non-abrasive (see the "Nonabrasive Alternatives" sidebar on p. 36). A considerable number of manufacturers supply a wide range of machine tools, drill motors and part holding fixtures to the composites industry. Over time, tool manufacturers have developed a variety of approaches for dealing with the unique issues presented by composite parts.

Because the high-strength fibers in composites don't break easily, they tend to be pulled by the cutting tool, leading to microcracking and delamination along the cut. In the case of aramid, the tough fibers are very hard to shear and result in fuzziness along the cut or machined surface. And, overheating at the drilling or cutting site can heat the resin above its glass transition temperature (Tg) and locally damage the cured laminate. When fluid is used to cool the work site, the fibers can absorb moisture, also degrading the laminate properties.

In addition, the tools themselves are put to the test when cutting composite materials. The heterogeneous combination of fiber and matrix resin means that a cutting tool encounters varying resistance due to the interlayered hard abrasive fibers and softer resin, which puts stress on the tool drive mechanism. Fibers, whether carbon, glass, aramid or metal, are abrasive and can lead to rapid tool wear.

HPC takes a look at how different types of tools can address these challenges, and how end-users are adapting them to best effect.

Carbide a cost-effective consideration

Composites manufacturers have the choice of cutting and drilling tools made from various materials, including high-strength steel, solid carbide and industrial diamond. Carbide is usually the material of choice for most applications, because it has the strength and durability to handle composite materials and is cost-competitive for high-production shops.

"A carbide tool will actually give you a more precise and cleaner cut than diamond," says Starlite Industries Inc.'s (Rosemont, Pa., U.S.A.) Jay Rosenbluth. "It does wear out fairly quickly because of the abrasive nature of the composite material, but lasts longer than steel."

Carbide, which was originally called carbaloy, was developed and patented in the 1920s by both General Electric and Krupp in Germany, and is itself a composite material, combining abrasive tungsten carbide particles and metallic cobalt binder. Traditionally, the powdered materials are mixed with solvents and paraffin wax, and then pressed into the cylindrical shape of the drill bit or mill or insert. The shape is then pre-sintered in an inert atmosphere at about 1,093°C/2,000°F to form an intermediate called "green carbide." At this stage the insert can be easily machined with standard grinding tools to form the angular cutting surfaces. The machined shape is then sintered again, at 2,760°C/5,000°F, to create the finished tool. Today, thanks to advances in CNC machining capability, most cutting toolmakers skip the green carbide stage and purchase sintered stock from carbide manufacturers, then machine the shapes to their own specifications. More exotic carbide-like ceramic-based compounds, including a compound called cermet that incorporates titanium in the matrix, are also available.

"There's a bit of witchcraft to making carbide," says International Carbide Corp.'s (Yelm, Wash., U.S.A.) Bruce Mackey. Many different grades of tungsten carbide are available, and manufacturers customize their recipes by adding metals like vanadium, and varying the percentages of tungsten and cobalt, to alter wear resistance, shock resistance and tensile strength. More tungsten means better wear resistance, but the trade-off is higher brittleness, says Onsrud Cutter LP's (Libertyville, Ill., U.S.A.) application specialist Thomas Cornwell. A higher percentage of cobalt binder improves shock resistance and resists cracking. Typically, a carbide insert drill bit or router bit has a transverse rupture strength -- essen-tially bending strength -- of 350 to 450 ksi, much higher than steel and nearly the same as the tensile strength of most composite reinforcing fibers. The material also can be coated to increase surface hardness and protect the carbide matrix, as well as increase lubricity for better chip removal. Typical coatings incorporate titanium or zirconium nitride.

Cutting geometries

Tool geometry, which refers to the angles and shapes of the cutting edges, was originally developed to cut metals and wood, and early efforts using these tools for composites caused problems. Cutting tools for metalworking were designed with neutral or even negative "rake" (i.e., the angle of the cutting face in relation to the work piece), to scrape and heat the metal to create plastic flow and efficient cutting. This design worked against composites, however, causing excessive heat and tending to push the fibers to the front of the cutting face, so that excessive pressure was needed to shear them and penetrate the part. A positive rake is preferred for composite materials, because the fibers shear more easily at that angle and a large amount of material chips can be efficiently removed with much lower generation of heat. Each manufacturer's exact rake angles and cutting edge geometries are proprietary and often patented.

"The analogy is shoveling snow," says Cornwell. "If you hold your shovel straight up, perpendicular to the snow surface [a neutral rake] it takes a lot of strength to push the snow from that position and the snow just piles up in front of your shovel. It is much more efficient to lower your shovel to an acute angle [positive rake] and get under the snow and push it out of the way."

Both the rotation speed of the spindle and the "feed rate" or the speed at which the tool moves through or across the part are important for a precise cut that penetrates the material without overheating. "A high chip feed rate is how heat is dissipated and the ideal chip form in composites is dry and powdery like confectioner's sugar," says Mackey. "If the spindle rotation speed is too high, and the chips aren't shoveled away fast enough, too much heat will be generated and you run the risk of melting the resin and damaging the tool as well as the part."

Through an iterative design and testing process, a number of tool manufacturers have developed carbide tools optimized for composites that take all of these issues into account. Starlite has manufactured carbide router bits, drill bits, trim saws and countersinking tools specifically targeted for aerospace composites since 1945, Rosenbluth points out. The company also makes a range of diamond tools (described below). It buys raw carbide stock, and then CNC machines its proprietary cutting designs.

One of Starlite's specialties is drill bits for aramid laminates. According to Rosenbluth, aramid fiber is the hardest to cut, much more so than carbon or glass. The company makes two tools for aramid: its Brad Point drill (or Forstner bit) has three intersecting cutting edges and spiral flutes at an approximate 35° angle for chip removal. Its patented shearbore drill for aramid has a single flute that produces a two-sided shearing action, allowing each fiber to be cut individually and lessening drill pressure requirements -- and thus heat. "Aramid fiber is a real challenge," he says. "It's very tough to break, but these types of tools produce high shear forces that minimize material delamination."

For precision drilling typical of aerospace parts, where hole size is critical for proper fastener fit and function, Rosenbluth points out that rigidity is more important than rotation speed. The part must be fixtured or clamped tightly to prevent movement. If a handheld drill will be used, he recommends a bushing inside a frame placed over the hole, which keeps the tool vertical and prevents any side movement, which can risk enlarging the hole.

Starlite often prototypes new tools to customer-generated specs and typically tests new tool designs at customer facilities, which in turn helps foster engineering improvements. Cost-effectiveness is enhanced by the company's program whereby customers can send back tools for resharpening, without having to purchase entirely new tools. The Boeing Co. (Chicago, Ill., U.S.A.) is one of Starlite's aerospace customers, and uses a wide variety of tools at several of its aerospace facilities.

Onsrud Cutter produces tools for a variety of industries, including composites. Cornwell agrees that carbide is the most cost-effective approach for routing composites. The company produces carbide router bits, primarily for deflashing parts or producing a smooth profiled edge for secondary processing, such as bonding. Onsrud has some measure of control over its carbide tools' material characteristics, since its sister company Bohlerit GmbH (Kapfenberg, Austria) produces and sells carbide material. Onsrud buys the sintered stock and machines its designs.

The company recently introduced three new router bits, each suited to a specific composite material. The Un-Ruffer bit is similar to a traditional fiberglass "burr" tool and is cut with spiral flutes in both directions, essentially creating a diamond pattern of multiple cutting points that cut small chips. Intended for use in sandwich panel applications, the bit provides a finer edge finish than a burr and reduces the risk of delaminating the skins, says Cornwell.

The carbon router, or CG-style bit, features multiple deep flute geometry and what Cornwell calls "up/down compression spirals." These dual-action flutes direct chips toward the center of the cut while presenting more cutting surfaces to ensure a clean cut. The FMR tool is designed for aramids, with larger, more open flutes and a modified rake. Many major airframe manufacturers and job shops in the aerospace industry are using Onsrud's router bits, says Cornwell.

International Carbide has developed some unique drilling products for composites, including the Hole-O-Magic cutting tool, which is essentially a carbide drill bit, bushing and driver/coupler in one device, for producing consistent, repeatable holes for fiberglass or carbon thermoset composites. The company's products are designed with positive rake for efficient fiber shearing, to avoid the "crumbling" of the resin that can result under too much compression.

The specific application and the required production rate are important factors in cutting tool choices. Mackey cites the case of a customer who was using a diamond router to smooth the inside of a fiberglass composite bus window frame, with a total trim length of approximately five feet, in about five minutes. With a carbide router designed with a positive rake, the job time was reduced to just over one minute. While the $50 (USD) diamond router bit lasted about three weeks, it required a 0.5-hp motor. The $15 carbide router bit lasted about eight hours, requiring a motor one third as large and much lighter in weight. Gaining three times the productivity was in this case enough for the fabricator to switch to carbide, despite the fact that the tool wear rate was faster, says Mackey.

The motors that drive the tools can be either electric or pneumatic and are sold separately by a number of motor manufacturers. Andrews Tool Co. Inc. (Arlington, Texas, U.S.A.) makes pneumatic drill motors exclusively for aerospace customers, including Boeing, Lockheed Martin and Northrop Grumman. Company president George Andrews believes that pneumatic motors, driven by compressed air, are a better solution, because of the possibility for carbon fibers to short out and burn up an electrical motor when drilling carbon fiber composites, despite dust collection measures. All of Andrews' equipment has controlled power feed mechanisms, which means the tool advances automatically under controlled air pressure, without any input from the operator. This ensures that undue pressure isn't put on the tool to force it through and "blow out" the underside of the panel, says Andrews. The drill motors are all equipped with onboard vacuum systems, which collect the dust generated by the drilling operation.

Are diamonds a fabricator's best friend?

Diamond, the world's hardest substance, is a more expensive yet higher performance alternative to carbide tools. Diamond tools offer much longer life than carbide -- in some cases, hundreds of times longer. The diamonds are either synthetic, industrial polycrystalline diamond (PCD) material, produced in a proprietary high-temperature process by several manufacturers, including De Beers, Diamond Innovations (formerly part of General Electric) and Sumitomo Electric, or natural diamond grit.

A diamond tool is created by adhering a thin (less than 1-mm/0.04-inch) layer of diamonds to the substrate. The trick is the attachment, and several methods have been developed. The most common and least expensive is electroplating, in which a metal stock shape is submerged in a nickel solution that contains diamond grit -- natural or synthetic -- in suspension, causing the diamond particles to adhere to the metal surface. According to Starlite's Rosenbluth, as this type of tool is used, the diamonds gradually lose adhesion and fall out, so it's best suited to low-production rate applications. A higher-performance method is braze bonding, in which diamond grit is brazed or soldered to the underlying metal. The diamonds become part of the tool surface, with the diamonds held by a metallic alloy to the tool body. These tools can withstand higher rotation speeds and heat during the grinding or cutting process, and the diamonds stay embedded longer.

PCD tools are made with segments of polycrystalline diamond that has been pressed under extremely high heat and pressure into a carbide substrate. PCD manufacturers sell "blanks" or segments of this material, which tool manufacturers then braze onto a carbide tool body to form a cutting lip or edge. The tool works like a carbide tool but with a flat cutting plane and typically straight flutes for chip removal.

A more innovative method is chemical vapor deposition (CVD), in which a thin film of crystalline diamond, just a few angstroms thick, is deposited directly on a tool body in a microwave plasma assisted process. CVD tools tend to have more geometry and cutting edges, rather than the flat, straight surfaces of a PCD tool.

An issue with diamond cutting and drilling is that, while the tool has a longer life, it can generate higher heat depending on tool speed and may require coolant. Some manufacturers recommend liquid or air coolants, but liquid coolants can damage the composite part by infiltrating the fibers or affecting the surface of the composite part, requiring cleanup and surface preparation prior to painting. For that reason, most diamond drills are run dry, but contact time must be monitored to keep temperatures as low as possible, and the dust is typically collected.

Besides long life, diamond tools also offer dimensional stability. Unlike carbide bits, which wear and erode over time and become smaller in outer diameter, a diamond drill or router bit diameter remains more consistent, since only microscopic grit is being worn off. Because diamond tools work primarily by grinding rather than cutting and shearing, they typically have flat edges (neutral rake) and straight, rather than spiral, flutes. This can cause problems when cutting or machining tougher aramid fiber laminates, because shearing is difficult, so fuzziness can result.

Each fabricator must make the call as to whether diamond's higher cost is justified for each specific application. Automotive composites manufacturer MacLean Quality Composites (West Jordan, Utah, U.S.A.) has used both carbide and diamond bits and reports that, while both offer advantageous features, diamond bits prove most cost-effective when a two-phase strategy is followed. MacLean technicians had observed that very coarse-grit diamond bits tended to tear the composite, while finer bits tended to load up, or clog, with carbon dust. Therefore milling or drilling typically begins with a coarse bit, for speed, but is finished with a finer grit bit for smoothness, depending on the customer's specifications. Finer diamonds and a really clean surface require coolant, while coarser cuts can be dry cut. To mitigate diamond's greater cost (custom 0.25-inch diamond bits with pilots cost in excess of $50 each), MacLean also takes steps to optimize the useful life of each bit. When routing demolded part edges with a diamond bit, for instance, the CNC machine can be programmed to intermittently use a different part of the bit, or cycling the bit up and down in a "wavy" pattern, so the point of contact with the composite surface is constantly changed. This minimizes heating, makes use of the entire tool and ensures even tool wear for cost-effectiveness. R&D manager Randy Smith notes, "Our bits are always custom ordered, so lead time is part of the equation in choosing a vendor. We try to keep it to one to two weeks."

Starlite's diamond products include router bits, countersinks, and saws in both electroplated (Magnicon Bond) and brazed ("B" Bond) versions, as well as PCD countersinks. UKAM Industrial Superhard Tools (Valencia, Calif., U.S.A.) offers its proprietary Smart Cut diamond technology, which the company claims orients and aligns the diamonds in a more regular manner during electroplating, for longer tool life.

Carter Diamond Tool Corp. (Willoughby, Ohio, U.S.A.) has supplied a wide range of milling, grinding, drilling, routing and cutting tools since the 1920s. Both PCD and natural diamond tools are available in four basic styles or geometries, says president John Carter. The company will modify and redesign diamond tools for customers and offers a cost-effective reconditioning service for any tool as an alternative to purchase. Other diamond tool suppliers include Diamond Productions Canada Ltd. (Montreal, Quebec, Canada), Niagara Cutter (Amherst, N.Y., U.S.A.), National Diamond Laboratory (Los Angeles, Calif., U.S.A.), Cranden Diamond Products Ltd. (Cranbrook, Kent, U.K.), Diamix (Chassieu, France) and Diatrim Tools Ltd. (Montreal, Quebec, Canada).

CVD Diamond Corp. (London, Ontario, Canada) uses the chemical vapor deposition process to create end mills. An advantage of vapor deposition is that it can coat even steeply raked tools, similar in design to carbide tools. The thin coat (a few angstroms thick) wears more quickly than a PCD tool, although it lasts about 20 times longer than carbide, says CVD's president Joe Brennan. CVD produces diamond coated end mills from 1/64-inch to 1/2-inch diameter for trimming and cutting.

Waterjet methods

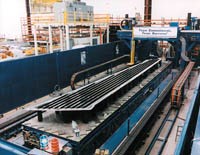

All of the "hot" methods described above generate friction and high heat, which have the potential for damaging composite laminates. In contrast, waterjet cutting is a low-temperature, controlled-erosion alternative that doesn't introduce any heat or heat-related stress to the material and is unaffected by the heterogeneity of composite materials, says Dr. Mohamed Hashish of Flow International Corp. (Kent, Wash., U.S.A.), the inventor of abrasive waterjet technology. Flow was started in 1974 by a group of Boeing engineers searching for an alternative cutting method, and the company is currently the only supplier of waterjet cutters for aerospace.

Waterjet cutting works with either a mechanically driven, direct-drive pump that pressurizes water in a small cylinder with a plunger, or with a hydraulically driven intensifier that pressurizes water in a larger cylinder. The intensifier pump is slightly more costly but requires less maintenance and is better suited to high production rates. A waterjet cell consists of a pump, computer controller, "manipulator" (two or multi-axis) that includes the jet orifice and a table/catcher for supporting the part and collecting the water and abrasive. For some applications, the water and abrasive is collected and recycled, but typically for composite cutting it is too difficult to remove the bits of fiber and resin from the abrasive.

In accordance with Bernoulli's Theorem, when the high-pressure water is forced through a very small-diameter orifice, the result is a high-velocity waterjet moving at more than 914 m/sec (3,000 ft/sec) but at nearly ambient pressure, says Hashish. To withstand the erosive effect of the high velocity, the orifice is made from low-wear diamond or sapphire. Abrasive garnet grit, which gives the water its cutting ability, is introduced by the vacuum effect of the stream in a mixing tube. A "focusing tube" typically made from special-grade tungsten carbide dictates the final diameter of the hole being drilled or the shape of the edge profile. Focusing tube diameter is usually 1 mm/0.040 inch, and as the carbide wears, the tube is periodically replaced.

Because the jet force is low, the part doesn't require extensive fixturing to hold the part in place. While high-velocity water alone will cause delamination of a composite laminate, water with abrasive typically will not. Flow's director of marketing Michael Ruppenthal says that the company developed a vacuum assist feature that adds the abrasive garnet upstream of the focusing tube, so that the part is never subjected to water alone. The amount and size of abrasive can be tailored for the type and thickness of the composite to achieve the fastest cut. According to Arnie Lytle of LAI-Southwest Inc. (Phoenix, Ariz., U.S.A.), a Flow customer who does custom cutting jobs for its clients, less than a second is needed to drill a hole through a 12.7 mm/0.5-inch thick carbon composite panel.

Besides the cold-cutting feature of the water stream, another advantage is that one jet can be used to cut or drill a wide range of materials and thicknesses -- there are no tools to change for higher productivity, says Ruppenthal. Plus, the technology can be easily automated.

Boeing has used waterjets for years, for its Boeing 777 tail parts. Aircraft manufacturer Raytheon is another Flow customer, and uses a waterjet to cut composite parts for its Premier 1 jet. LAI Companies (Westminster, Md., U.S.A.) is a waterjet job shop that uses numerous Flow systems for its custom cutting jobs.

"Composite design engineers often don't consider the mechanics of part cutting," concludes International Carbide's Mackey. "But the technology is pretty important to the ultimate success and profitability of the project."

Sidebar

Nonabrasive Alternatives

Nonabrasive methods for composites include laser beams, electrical discharge machining (EDM), ion beam and electron beam cutting, and microwave cutting. Laser cutting typically uses YAG (yttrium aluminum garnet) or CO2 lasers, which vaporize or melt the material to create the cut or hole. Carbon fiber is very difficult to melt, says Dave Woodward of Laser Applications Inc. East (Westminster, Md., U.S.A.), and thermal damage to the part can result in the heat-affected zone (HAZ) adjacent to the cut. Laser machining also causes aramid fibers to give off toxic gases, which makes working conditions hazardous. On the plus side, material loss is minimal because the cut area is very thin, virtually no setup or work fixturing is required and no tools are needed -- a technician simply shines the light beam on the work piece.

EDM requires the work piece to have an electrical resistivity of less than 100 ohm-cm (i.e., highly conductive). Thus it can't be used for fiberglass or most ceramic matrix composites. The tool and the work piece are connected to electrodes separated by a dielectric fluid. Electrical energy is converted to thermal energy, which removes material by melting and spalling. Because the melt zone can contain microcracks, EDM's use for composites is still being developed. EDM is used to cut polycrystalline diamond (PCD) materials that are used for abrasive machining.

Ion beam, electron beam and microwave cutting methods are typically only applied to thin sheet material and can't be applied to contoured surfaces that require machining to tight tolerances.

Related Content

Film adhesive enables high-temperature bonding

CAMX 2024: Aeroadhere FAE-350-1, Park Aerospace’s curing modified epoxy, offers high toughness with elevated temperature performance when used in primary and secondary aerospace structures.

Read MoreIPSA acquires bonding adhesives based on MMA technology

IPS Adhesives (IPSA) introduces a line of adhesives using acrylate and MMA technology from L&L Products for the bonding of dissimilar materials such as metals and composites.

Read MorePark Aerospace launches aerospace, MRO structural film adhesive

Aeroadhere FAE-350-1 is a curing epoxy formulation designed for composite, metal, honeycomb and hybrid applications.

Read MoreSyensqo introduces AeroPaste 1003 aerospace adhesive

Two-part room-temperature paste increases high-rate assembly and joining efficiencies when bonding metallic and composite parts.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More