Applying UV-curable powder coatings to composites

Keyland Polymer UV Powder reviews the features, benefits and applications of its UV-curable powder coatings in a composites manufacturing environment.

Keyland Polymer UV Powder (Cleveland, Ohio, U.S.), a developer, formulator and manufacturer of UV-curable powder coatings that instantly cure with UV light energy, in this Digital Demo reviews the benefits and application of UV powder coatings in a composites fabrication environment. UV powder coatings are a safe, solvent-free and energy-efficient coating system suitable for a variety of heat-sensitive substrates including composites, plastics and wood as well as traditional metals. This coat and cure Demo introduces UV-cured powder coatings and the advantages of the technology.

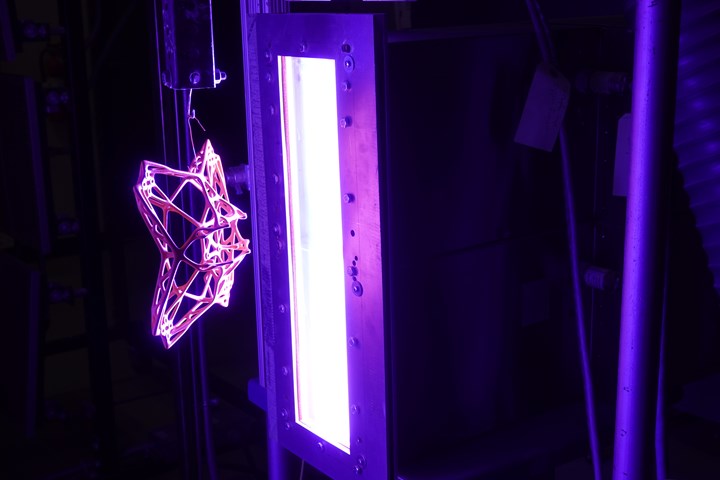

The presentation includes the use of UV-cured powder coatings integrated with HP MJF (multi-jet fusion) technology to produce a 3D printed drone body component. Keyland Polymer’s R&D chemist demonstrates the plasma pretreatment process used to prepare the surface, followed by UV-cured powder coating application and UV curing. The demo ends with an adhesion test of the finished drone body.

For more information on this and other Keyland Polymer products, visit kpuvpowder.com and follow them online LinkedIn and Facebook.