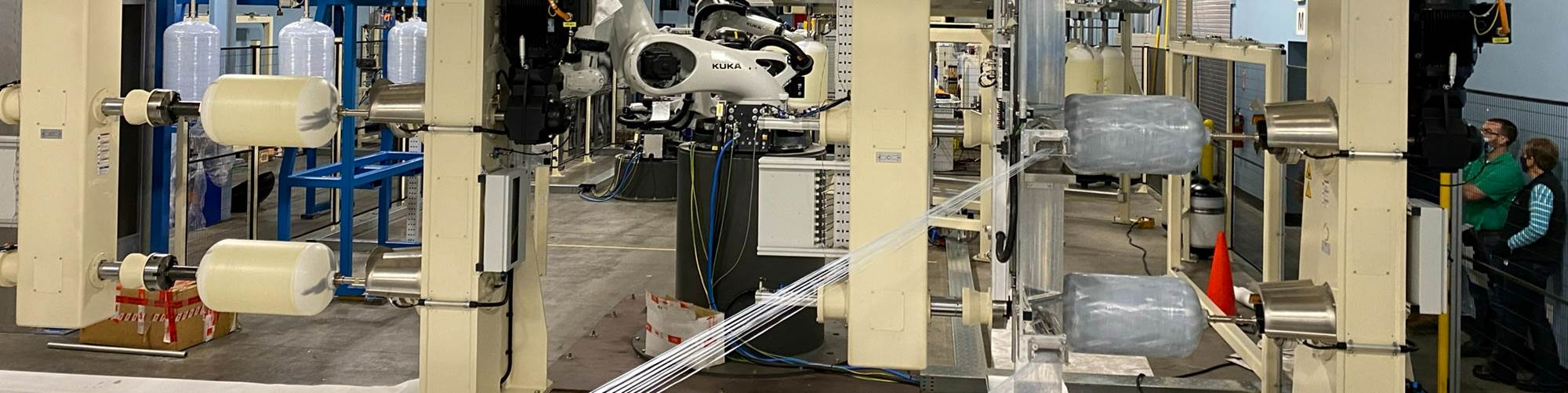

Pressurized well tank manufacturer Amtrol recently installed an automated filament winding line with in-process monitoring to produce its debut product line of composite-lined tanks. Pictured here, a KUKA robotic arm moves the polypropylene inner vessel along the system for filament winding. Photo Credit: Amtrol

Amtrol (West Warwick, R.I., U.S.) invented its first pre-pressurized well tanks in 1963. These tanks store water under pressure to reduce pump run time, decrease pump cycles and protect the overall system, Mike Giannantonio, general manager – cylinders and water systems at Worthington Industries (Columbus, Ohio, U.S.), says. Amtrol has run a successful business producing steel well tanks for nearly 60 years, but in recent years has invested in the technology to develop a new composite tank line, thanks to the composites experience and financial resources of Worthington Industries, which acquired Amtrol in 2017.

Filament-wound composite tank technology has been around for a few decades, but according to Alex Spires, senior project manager at Worthington Industries, this technology has evolved and gained adoption in the well tank market over time. Composite well tanks, he says, provide benefits to the market including reduced condensation, increased durability and weight savings.

With Worthington Industries, Amtrol’s new composite tank link includes tanks of various sizes, consisting of a polypropylene inner vessel and a thin glass fiber/epoxy exterior wrapping.

Over the last few years, Worthington Industries worked with Roth Composite Machinery (Steffenberg, Germany) to develop a filament winding system to meet Amtrol’s needs for an efficient, automated process to manufacture these relatively high-volume tanks in various sizes. Incorporated process monitoring capabilities were also important to ensure Amtrol’s market-recognized quality standards. Roth Composite Machinery was chosen after years of supplying filament winding systems for Worthington Industries’ European facilities, which manufacture higher performance composite tanks to store hydrogen and other high-pressure substances.

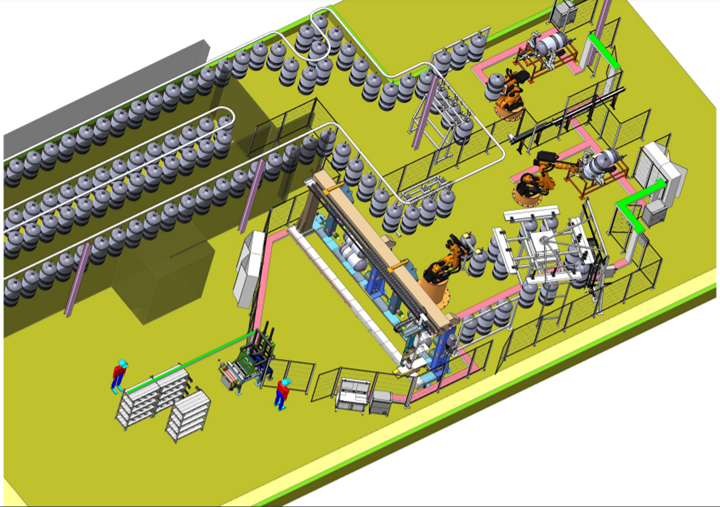

This overhead illustration shows various stations of Amtrol’s filament winding line. Controlled by two human operators, tanks are moved through testing, winding and curing stations via three robotic arms and conveyors. Photo Credit: Roth Composite Machinery

Automated filament winding line with in-process monitoring

The system, installed in late 2021, consists of a highly automated process located in a newly constructed, climate-controlled wing of the Amtrol facility.

For each tank, first a polypropylene inner vessel is manufactured separately. Each tank going through the system is serialized with an RFID tag to record information such as the operator who built the tank, the temperature at which it was cured, the number of windings, the ratio that the epoxy was mixed and leak test data. “It records all of that in a database that we keep with our quality systems. If there should ever be any issue in the field, we can check that RFID tag and go back to the production data to root out any issue. Additionally, the RFID tag allows for inventory tracking for both Amtrol and our customers,” Spires says.

Each polypropylene vessel is fitted with an RFID tag, pressurized and flame treated before winding. Photo Credit: Amtrol

Each polypropylene tank is fed by an Amtrol operator onto a conveyor system, where it travels to the first station of the Roth line, the liner input station. Here, a production shaft is inserted into each liner with a controlled torque setting. A robot places the liner onto a carousel. The carousel can hold up to four liners; once filled to capacity, it rotates 90º, at which point the liners are pressurized and flame treated (see video below). The carousel then rotates another 90º, where the surface-treated liners are pressure checked for leaks. If all pass, the carousel rotates an additional 90º and a robot moves the prepared vessels from the carousel to an automatic filament winding system.

The filament winding cell consists of Roth’s “twin” winding machine (see video below), which offers winding on one side while the other side automatically loads and unloads the vessels via a robot. Once the winding is complete for each vessel, the fiber is automatically cut and attached to the finished vessel. Then, the winding carriage is automatically moved to the other side of the winder and winding continues on the next vessel. Depending on the size of the vessel, winding times are around five minutes per vessel, and the twin system enables near continuous winding during production.

Spires notes, “The Roth winding equipment allows for the optimization of the glass overwrap winding patterns to provide optimal protection and a reduction of the overall amount of material on the tank.”

Roth Composite Machinery’s twin winding system winds two tanks at once (pictured right) while two more tanks await loading (left). Photo Credit: Roth Composite Machinery

As each vessel is completed, it is transferred via robot onto a temperature-controlled conveyor feeding it to the curing oven. The cured vessel exits the curing oven and is unloaded via robot into a test station where production shafts are removed, followed by final pressure and leak tests. If all tests are successful, the finished part is automatically moved from the production cell via conveyors to Amtrol’s packing and shipping area.

Amtrol Titan is the first composite tank well tank product line to be introduced by the company using the new automated production line. A second product lineup is expected to launch in late 2022. Photo Credit: Amtrol

According to Joe Jansen, national sales manager for Roth Composite Machinery, the system only requires one to two people to operate, compared to up to five to six people needed to run multiple manual filament winding systems. He also says the Roth automated cell is able to outproduce that of three separate, manual filament winding machines.

Jody McKinley, director of engineering at Amtrol, notes, “The quality and flexibility of the Roth winding equipment is second to none and allows for future growth opportunities of our company through adding new products and reducing the need for additional human capital due to the automated nature of the work cell.”

Following 2021 installation, Amtrol’s new Amtrol Titan tank line launched in summer 2022. A second, higher performance composite tank brand called Amtrol Lift is expected to launch later this year.

Related Content

Syensqo becomes new Solvay specialty materials company

Syensqo represents what was Solvay Composite Materials, focused on delivering disruptive material technologies and supporting growing customer needs.

Read MorePartners recycle A350 composite production waste into adjustable-length rods for MFFD

Herone, Spiral RTC, Teijin Carbon Europe and Collins Aerospace Almere recycle A350 thermoplastic composite clips/cleats waste into rods for the all-thermoplastic composite Multifunctional Fuselage Demonstrator’s crown.

Read MoreDawn Aerospace reusable rocket-powered aircraft flies twice in one day

Eighth and ninth flights of composites-intensive Mk-II Aurora reach an altitude of 63,000 feet, demonstrates same-day reusability capability for rocket-powered systems.

Read MoreTPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

Read MoreRead Next

Increasing demand for composite driveshafts leads to automated production

California-based fabricator ACPT Inc. worked with machine suppliers to build an innovative semi-automated production line featuring an automated filament winder.

Read MoreFilament winding, reinvented

Robots and digital technology deliver speed plus larger, more complex parts, while generative 3D winding obviates mandrels and waste for automotive applications.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;width=70;height=70;mode=crop)