Big machines, small tolerances

An examination of the lengths Janicki Industries (Sedro-Woolley, Wash.) goes to ensure dimensional precision in its massive CNC-machining operations.

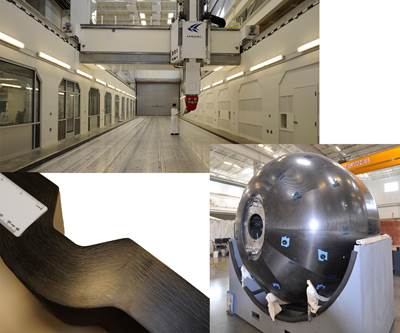

To accommodate the ever-increasing size of composite parts and the tools they require, Janicki Industries (Sedro-Woolley, Wash.) installed twin CNC mills, #5 and #6, in its Hamilton, Wash., facility. Among the largest in the world, the 100-ft by 20-ft by 8-ft (30.5m by 6m by 2m) machines were integrated into the facility as it was built. Specially designed reinforced concrete floors were poured to support the CNC machine gantries. The building was erected around them.

Massive filtration systems were developed to efficiently remove cutting debris and dust on large projects. Because the mills ride on 120-ft/36.6m steel rails, a temperature-induced change in dimensions can be problematic. (The linear CTE for steel at room temperature averages roughly 6x10-6 per 1°F (12x10-6 per 1°C), which produces a length change of 9 mils/0.2 mm per degree in a 120-ft/37m long rail.) For that reason, the temperature of the overall facility is held to within ±5°F/±3°C of the set point, and the CNC mill rooms are kept within ±1°F/±0.6°C of the set point.

CNC mill operations manager Eric Friesen claims that accuracy is what differentiates Janicki. “Despite the many CNC mill compensation systems available in the industry, we continue to write our own,” he points out. “The compensation systems you can buy simply do not work well on mills of this size and complexity.” Those systems assume certain mechanical accuracies in the machine, but Janicki prefers to measure and account for possible error instead. Friesen credits this attention to detail to Dr. John Weller, who runs the Automation and Mechatronics department at Janicki Industries. “He and his team of engineers have translated a 5-axis CNC mill into a huge mathematical problem, and then developed proprietary software to solve it with four- and five-decimal-place accuracy.”

The mill, as it glides on the rails, forms the x-axis, the carriage moves back and forth across the bridge in the y-axis, the mast moves up and down on the z-axis and the machine head “wrist” articulates and rotates, making up the final two axes. Compensation for inaccuracies is developed by “clocking in” the CNC machine.

“We mount a laser tracker in the head of the machine spindle and track its movement, using multiple lasers triangulating on its position as it moves through its volumetric envelope,” Weller explains. “We then use that data and our proprietary algorithms to solve a massive nonlinear system of simultaneous equations with millions of unknown coefficients. The hardware and software in modern computers make this possible and relatively easy. We have a program that takes the measurements automatically in a few hours, coordinating the movement and communication of the laser equipment and the mill. Then the math is solved on a PC in the controller in a few minutes and, presto! … we have a dead-accurate CNC mill in five full degrees of freedom to around ±0.002 inches. This is an astonishing feat for machines that are large enough to produce tooling for wind turbine blades or wings on commercial aircraft.”

Another example of this accuracy is geometric tolerancing of holes. For Lockheed Martin’s F-35 parts, the accuracy of the hole centerline had to be within a 0.007-inch/0.178 mm diameter cylinder (on the scale of human hair). Over a period of more than two years, Janicki claims it has drilled more than 500,000 holes in F-35 components within this tolerance without a miss. During HPC’s tour, Friesen showed a machined structure that had to meet a surface flatness and roundness of profile tolerance of ±5 mils (0.005 inch/0.127 mm) — the thickness of a sheet of paper. “When you get this low in surface deviation,” he notes, “you have to blow the dust off the surface before you take measurements or it throws you off. Right now, the degree of accuracy of our mills is bumping up against our ability to measure it. So we are as accurate as can be measured.”

Why such attention to accuracy? CEO Peter Janicki replies, “In the end, our customers get accurate tools that produce accurate parts.” Accurate parts cascade benefits throughout the program. A reduction in hand sanding and finishing saves much time and cost during assembly. “It also results in superior cosmetic surfaces,” he adds, pointing out that “the more someone sands and polishes on a tool, the further away it gets from the original intent of the CAD model, modifying subtle feature lines and other details.”

Related Content

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreComposites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Read MoreAchieving composites innovation through collaboration

Stephen Heinz, vice president of R&I for Syensqo delivered an inspirational keynote at SAMPE 2024, highlighting the significant role of composite materials in emerging technologies and encouraging broader collaboration within the manufacturing community.

Read MoreNCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreRead Next

Janicki Industries: Breaking the mold

Once known only as a toolmaker, Janicki offers unique precision, production capability and problem solving as it pioneers leading-edge composites technology.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)