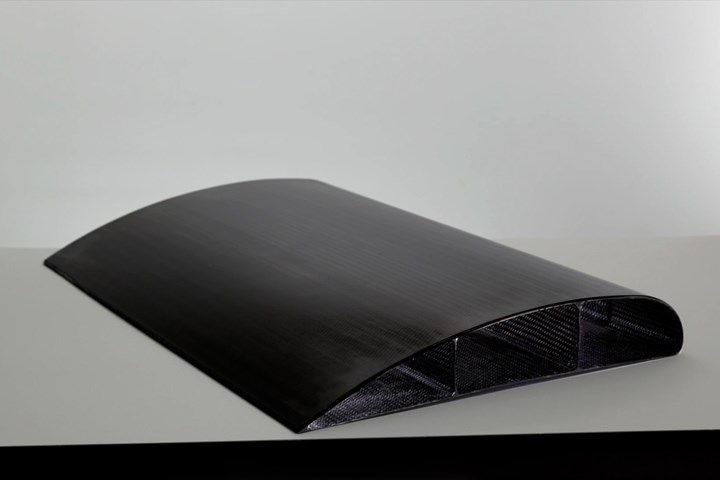

Spintech Holdings Inc. and its fabrication division Hawthorn Composites are using demonstrator components like this subscale tactical UAV wing to test and validate the use of infusion and preform technologies for more cost-effective aerospace and defense components. Photo Credit, all images: Spintech Holdings Inc.

Prepreg and autoclave cure have been the state of the art for aerospace and defense composite components for many years. Spintech Holdings Inc. (Xenia, Ohio, U.S.) and its fabrication division Hawthorn Composites (Xenia) are seeking to demonstrate that more cost-effective, less labor-intensive aerocomposite parts can be manufactured through the use of existing technologies — such as resin infusion and braided dry fiber preforms — in new ways.

Spintech originally spun out of Cornerstone Research Group (Miamisburg, Ohio, U.S.), with a focus on development of its innovative Smart Tooling shape memory polymer (SMP) tooling technology, which consists of reformable bladders, cauls or mandrels that can be reused for up to 100 production cycles. (For an in-depth explanation of Smart Tooling, watch Spintech’s digital demo). For the first few years after the company was formed in 2010, Spintech was funded primarily by Spirit AeroSystems (Wichita, Kan., U.S.), which allowed the company to scale up its technology for the possible manufacture of a single-aisle commercial aircraft fuselage with co-cured frames, stringers and skin.

In 2015, Spintech expanded to the broader aerospace market and in 2016, pivoted the process for making its Smart Tooling technology. “We went from an RTM [resin transfer molding] process that required a dedicated metal mold set to fabricate the Smart Tool, to being able to make them with VARTM [vacuum-assisted resin transfer molding] and to use the same mold set to reform the Smart Tools between cycles,” says Craig Jennings, president and CEO of Spintech Holdings Inc. “That eliminated about 40% of the capital cost to deploy Smart Tooling, so it really opened us up to a much broader market from a cost affordability perspective. We’ve been growing ever since.”

Beyond Smart Tooling, Spintech has also branched out into the manufacture of end-use components, a move solidified by the recent creation of its fabrication division, Hawthorn Composites, as well as partnerships with A&P Technology (Cincinnati, Ohio, U.S.) for the supply of braided products, and the University of Dayton Research Institute (UDRI, Dayton, Ohio, U.S.) for the development and supply of fiber preforms manufactured using the tailored fiber placement or technical embroidery process.

“Resin infusion isn’t new, but it’s the technology that the aerospace industry is adopting in a new way right now because they’re able to achieve big dollar reductions in composite parts with the same or even better properties.”

In the last few years, Spintech has demonstrated that RTM and VARTM processes, combined with Smart Tooling and dry fiber preforms manufactured using automated techniques, can be used for more cost-competitive end-use components in aerospace, defense and other markets.

“Using dry carbon fiber overbraid or tailored fiber preforms and resin infusion, we can drive down the cost of the materials significantly as well as the labor requirements, and be able to deliver the same quality at the same weight or even less in some cases when compared to prepreg, autoclave-cured parts. We think this is really where the market’s going over the next decade,” Jennings says. “We’re listening to our customers, and we’re positioning this division to take advantage of where the market is going and where our customers are going.”

To date, Spintech has demonstrated the cost-effectiveness of RTM and VARTM for various components, including, most recently, aircraft wings and inlet ducts.

Tactical UAV wing: Demonstrating positive-pressure RTM

Step 1. Smart Tools are wrapped with dry carbon fiber sleeves.

For years, Spintech has delivered Smart Tooling solutions for prepreg-based, autoclave-cured wings and control surfaces for small aircraft and unmanned aerial vehicles (UAV). Given the high cost of prepreg and autoclave cure, the company recognized that this was one application that could reap the advantages of combining RTM with Smart Tooling and braided preforms. To prove out this technology and process, Spintech recently built a small-scale tactical UAV wing demonstrator based on the designs used for full-scale customer projects. This demonstrator would also be the appropriate scale and complexity of a control surface for larger aircraft.

Step 2. Within the bottom half of the RTM tool, layers of QISO fabric and wrapped Smart Tools are placed into alignment.

To make the wing, first, two layers of A&P’s QISO quasi-isotropic braided triaxial fabric are laid into the bottom half of the RTM tool to form the lower wingskin. Three Smart Tools are wrapped in braided dry carbon fiber sleeves supplied by A&P Technology, and secured in their proper alignment on top of the QISO fabric layers. To create the trailing edge of the wing, an A&P-supplied net-shaped noodle preform, which is a braided cord with a triangular cross-section, is placed into the tool. “The lower and upper skins come together on that net-shaped noodle geometry,

Step 3. Custom “noodle” preforms are placed within the gaps between Smart Tools and along the trailing edge of the part.

which greatly simplifies and reduces the touch time for lamination, because we’re not having to roll our own noodles or put a bunch of individual carbon tows in there [to make the trailing edge shape],” says Tom Margraf, president of Spintech Holdings Inc. “We’ve got one continuous product that we just cut to length and drop in.” The QISO fabric in the bottom half of the tool is cut long enough that the excess is folded over the noodle area, and then the two top skin layers are brought over the aligned Smart Tools and trailing edge to complete the layup. The upper mold half is then closed over the lower mold half and sealed and bolted together. Attached next are intermediate seal plates, which contain holes so that a cavity runs all the way through the three Smart Tools. Vacuum bags are inserted through the Smart Tool cavities and sealed to the intermediate seal plates. This is followed by adding pressure plates to seal the mold.

Step 4. The RTM tool is closed and sealed.

Once the RTM tool is closed and sealed, vacuum is pulled, which, Margraf says, “gives us a sealed cavity where the dry fiber preform is now contained. By creating that sealed environment, it also allows us to apply positive pressure on the inside of the Smart Tools. That’s a really unique thing that no other solution in the market can do.”

For the wing demonstrator, 75 psi of pressure is applied inside the Smart Tools. During the RTM process, the Smart Tools are in their hot, elastic state and the internal cavity pressure creates a semi-rigid wall to inject the resin against. “As long as we maintain a 20-psi pressure differential such that the inside of the Smart Tool is always 20 psi ahead of the RTM pressure, we are guaranteed that the Smart Tool is in its proper position and that we’re getting good compaction on the laminate,” Margraf says.

Step 5. Vacuum bags are pulled through the Smart Tools and pressurized.

He adds, “The Smart Tools are designed to be undersized by the composite laminate bulk factor so they’re slightly smaller than the actual final inside moldline part definition. We do that to actually lower the force requirement for RTM.”

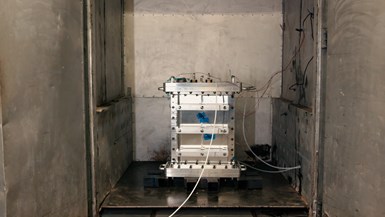

The infusion process takes place inside an oven, where the resin temperature within the infusion vessel is elevated to 125°F, and the part temperature is heated to 176°F. After infusion, temperature is ramped up to 250°F for part cure (Smart Tools are said to be compatible with cure temperatures up to 375°F), and once the dry fiber preform is fully wetted out, the resin inlet within the tool is closed, allowing the 75-psi internal cavity pressure to fully consolidate the laminate and expel excess resin.

“We can create a low-pressure RTM process with autoclave-like fiber volumes,” Margraf says. “Because the laminate is not initially debulked, the resin is going to flow and permeate that dry fiber preform much more easily than a traditional RTM process with matched-metal tooling.” Internally, the Spintech team calls this the “reverse autoclave effect.”

Step 6. The part is infused at elevated temperature within Hawthorn’s industrial-scale oven.

System cost savings come from the use of an oven instead of an autoclave, and the use of a lower-pressure RTM system. “We don’t need to go to 200 or 400 psi on the RTM system; most of our parts are infused at 50 psi positive pressure or less. We’re using significantly lower-cost capital, not just by not using an autoclave, but by using a lower-pressure RTM system as well,” Margraf says.

Step 7. The final part is extracted from the tool.

“What we’re finding is that the material savings alone is probably about a third of what it would be to buy prepreg to make the same part, and then there’s also significant labor savings,” Jennings adds. “Overall, the savings on something like this is easily in the 20-50% range on the total cost of the part.”

Step 8. The Smart Tools can then be reformed for further use.

This technology can be used for other general aviation components, as well. In late 2020 and early 2021, Spintech used RTM to demonstrate a lower-cost method for manufacture of a multi-cavity general aviation tank. According to Margraf, fabrication of tanks with prepreg costs about $30,000 per tank. Converting to RTM with Smart Tooling and braided preforms reduced the cost to about $10,000 per tank. “We were roughly one-third of the cost going with this approach versus the prepreg approach, and it’s a structurally equivalent part that is actually about 15% lighter weight than the prepreg part, because we were able to use a continuous braid instead of discontinuous layers of prepreg laminated and joined together,” he says. This approach also reduced production time from about a week to less than a day.

VARTM for commercializing more cost-effective inlet ducts

Spintech also has demonstrated VARTM for components where the inner moldline is most important, starting with a tactical UAV inlet duct which is based, like the wing demonstrator, on prepreg/autoclave designs that the company was already making. According to Margraf, Hawthorn first manufactured five inlet duct parts for its customer, using carbon fiber prepreg laid up on a Smart Tool with a barrier release and cured in an autoclave. However, Spintech knew that switching to a braided preform with resin infusion would save labor and material costs, and wanted to find out exactly how much the savings would be. “At our own expense, we then went through and actually manufactured structurally equivalent braided parts, using VARTM, and then analyzed the cost savings associated with that conversion from prepreg to braided infusion,” he says.

The preform for the duct, Margraf explains, is pre-manufactured to the proper geometry on a braiding machine at A&P Technology’s Cincinnati facility. Once delivered to Hawthorn, the preform is hand-applied to the mandrel. “It’s hand layup, but it still offers significant time savings because we’re applying one full braid layer that covers the entire wetted area in one preformed sleeve. We pull on and locate the one layer in about five minutes, whereas the equivalent work to do that with a prepreg laminate layer took in excess of two hours because you’ve got potentially dozens of separate pieces of prepreg to get the same structural equivalency as one 12k braid layer,” he says.

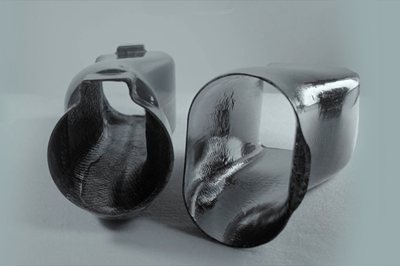

A finished inlet duct demonstrator (right) sits next to its corresponding Smart Tool (left).

The customer looked at using a multi-piece aluminum mandrel versus a Smart Tooling solution, but the capital savings on the tooling alone was a 46% reduction, from $75,000 to $40,000. There is also a 67% reduction in touch time to produce the part with the conversion from prepreg to dry fiber braid and infusion. Overall, cost to the customer would be reduced by almost 50% per part, Margraf says.

On Feb. 1, Spintech announced that Hawthorn has been awarded a manufacturing contract from Kratos Defense & Security Solutions Inc. (San Diego, Calif, U.S.), to provide 12 inlet ducts for the XQ-58A Valkyrie unmanned combat aerial vehicle, using Smart Tooling, VARTM and braided preforms.

“Ultimately, this technology is transitioning to multiple different customers and multiple different markets,” Margraf says. “From general aviation tanks, to large tactical UAV components, to eventually commercial aircraft components.”

The future of aerocomposites

The Spintech team believes this technology is the way forward for many aerospace and defense components. With existing customers already reporting 20-50% cost reductions over traditional processes, the goal for larger-scale acceptance certainly seems within reach.

“As you consider what’s cutting-edge for aerospace manufacturing, resin infusion isn’t new, but it’s the technology that the aerospace industry is adopting in a new way right now because they’re able to achieve big dollar reductions in composite parts with the same or even better properties,” Jennings says. “The cutting-edge part is the automation. We now have the ability to do it with automated methods like braided preforms and tailored fiber placement that have yet to be widely adopted. The automation, in combination with lower cost dry fiber and resin, makes all the difference.”

Related Content

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreRead Next

Braided preforms meet phase-change tooling

A program from the U.S. Air Force Research Laboratory adopts automated braiding and phase-change tooling for a complex geometry unmanned aircraft part.

Read MoreHawthorn Composites awarded structural inlet duct manufacturing contract

Manufacture of inlet ducts for Kratos unmanned combat aerial vehicle involves an automated dry fiber overbraiding process, VARTM infusion and oven cure.

Read MoreSpintech awarded two U.S. STTR program contracts

Spintech partners with UDRI, an eVTOL OEM and Aurora Flight Sciences to explore manufacturing methods and materials for optimized eVTOL aircraft components and production.

Read More

.jpg;width=70;height=70;mode=crop)