Build-to-print: Done Better

It’s hard to measure the transforming effect that unmanned aerial vehicles (UAVs) have had on modern warfare and security activities. Growing demand for these “drones” — for surveillance, aerial photographs and attack duties — has led to a phenomenal proliferation

It’s hard to measure the transforming effect that unmanned aerial vehicles (UAVs) have had on modern warfare and security activities. Growing demand for these “drones” — for surveillance, aerial photographs and attack duties — has led to a phenomenal proliferation of composites-intensive designs and concepts from a global supplier base. One of the many players in the U.S. UAV market is Insitu Inc. (Bingen, Wash., a subsidiary of Boeing Integrated Defense Systems Military Aircraft), which, with Boeing, developed the small (10-ft/3m wingspan) and successful ScanEagle Small Tactical Unmanned Aircraft System (UAS) for intelligence, surveillance and reconnaissance (see “Learn More,” p. 37). First flown in 2002, the ScanEagle has logged more than 10,000 combat hours and is considered an important tool for U.S. Marines and Navy personnel.

Because ScanEagle systems are in demand, Insitu works with a number of subcontractors to meet rate production. One of these is Cobham Composite Products (Cobham, San Diego, Calif.), which became part of Cobham plc when SPARTA Inc. was purchased in June 2008. “We are joining a superb company with an established record of success in the composite production business,” says Paul Oppenheim, Cobham’s VP and general manager. Cobham (and SPARTA) have worked closely with major defense OEMs to design, develop and implement composite manufacturing solutions for more than 25 years, adds Joel Zuieback, director of business development. Cobham has put this accumulated experience to work in the production of the ScanEagle’s complex winglets, using a combination of well-established manufacturing processes, including hand layup, bladder molding, and assembly and integration, all within a lean manufacturing cell.

Scanning the project parameters

The ScanEagle winglet — the vertical control surface at the aircraft’s outer wingtip — is a hollow symmetrical airfoil approximately 10 inches/254 mm high, about 6-inches/152-mm deep at the root, and tapers to 4 inches/102 mm at the tip, with a thickness of about 1 inch/25 mm. A servo-actuated, composite rudder is attached to the trailing edge of the winglet with an elastomeric hinge. A plastic fitting, injection molded to minimize cost, is bonded to the root end of the winglet and provides the attachment for the winglet to the ScanEagle wing.

The ScanEagle’s winglets must be robust because they are an integral component of the craft’s “skyhook” retrieval system, which involves flying the drone into a vertical cable. The cable slides along the wing leading edge to a hook at the wingtip, arresting flight. The winglet often takes the brunt of the load as the craft swings around the cable after capture.

“We produce Insitu’s designed winglets within our AS9100-certifed production facility,” says Zuieback. “We developed and qualified all of the controlled processes and procedures for rate production.

“Our system supports all of Insitu’s monthly delivery needs, which have averaged between 125 and 175 parts per month in one of four configurations to meet mission needs,” he notes. Cobham also produces winglets to meet Insitu’s ongoing spare-parts requirements.

To meet rate requirements, Cobham developed a bladder molding process, using a two-piece metal mold that is heated in a platen press, producing a winglet in a one-step process. While it’s a mature process for making hollow parts, the company has worked continuously to optimize its efficiency. Higher throughput has been achieved, in part, through a number of work-area changes, application of automation, and tooling improvements: “If we save a few minutes on each step by making things flow better, they add up,” he notes. “The thread that runs through our processes is finding ways to do things leaner and more efficiently.”

Designing the production process

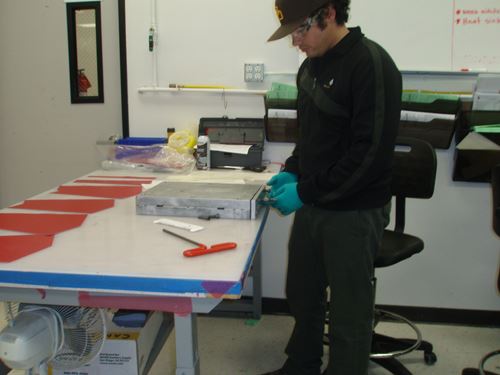

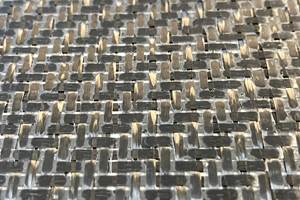

Cobham employs FiberSIM software from VISTAGY Inc. (Waltham, Mass.) to develop ply architecture and optimize material usage. The software works from CAD model information to produce a draping analysis of prepreg materials used in curved parts to minimize fiber distortion and maximize reinforcement properties to meet design requirements — in essence, this step involves translating the curved model into the most efficient flat ply shapes. About once a week, an automated CNC flat table cutter manufactured by American GFM Corp. (Chesapeake, Va.) rapidly cuts the proprietary 250°F-/121°C-cure glass/epoxy prepreg material into the required shapes, with no manual cutting. Technicians kit the materials for the following week’s shifts, and place the kits in the freezer. The kits required for the next day’s shifts are taken from the freezer the night before, to allow sufficient time for the materials to become drapable.Cobham created the aluminum clamshell tools for the winglet parts and designed and now produces its own inflatable silicone bladders inhouse. Multiple tool sets are used to maintain a continuous cycle of layup and cure. That is, while one tool is in the press and undergoing cure, the second is available for simultaneous layup of the next winglet. Further, the tools were designed to enable layup of the entire part, both the hollow airfoil and the monolithic trailing edge rudder, eliminating post-mold joining. Zuieback explains that more tooling improvements are in the works: “We’re developing a new tool with molded-in detent features to really simplify the post-cure finishing processes.”

According to Zuieback, the production area has been designed and organized so that technicians don’t have to walk away to pick up supplies or materials; the layup tables are located close to the presses, and materials and supplies are close at hand and ergonomically placed, measurably decreasing layup time for these relatively small parts. “We are now set up to handle current production, short-term ramps and long-term rate increases,” he says.

To make a winglet part, a tool is loaded with the pre-cut, kitted prepreg materials above and below the deflated silicone bladder to create the hollow airfoil. The bladder emerges from the underside of the winglet root and is connected to a hose that runs through a port machined at the tool parting line. Prepreg and hinge material also is placed in the mold for the winglet rudder. When the mold is loaded and closed, it is placed into one of Cobham’s four, 24-inch/610-mm heated platen presses built by laboratory press specialist Carver Inc. (Wabash, Ind.). The bladder is then inflated with shop air; as it expands it compresses the airfoil layup against the sides of the mold to ensure good consolidation. At this point, one of several in-process inspections takes place to ensure that the tool is completely closed. Says Zuieback, “This simple in-process inspection with a feeler gauge improves yield and reduces rework.” The press platen is then engaged against the tool and the cure cycle is initiated — parts take about one hour to cure given the prepreg’s fast-cure characteristics. Parts are demolded hot as soon as the tools are removed from the presses to avoid any coefficient of thermal expansion (CTE) issues as the aluminum tool cools down. The bladder is deflated and pulled out through the bottom of the part. Any flash is cleaned and all parts are inspected for defects.

At this point, batch trimming and finishing steps are undertaken in Cobham’s production machine shop. The company has designed and implemented a vacuum chuck system for its CNC machining center. The chuck securely holds each winglet part in place while all cutouts are routed and trimmed in a single operation — not only saving operator time, but also diminishing the risk of damage to the part during conventional re-fixturing, explains Zuieback. Then, the injection molded plastic fitting, manufactured by R.S. Alberts (Montoursville, Pa.), is bonded into the inboard, machined cutout using a proprietary epoxy adhesive; the fitting slides into the outboard Scan-Eagle wing for mounting the winglet.

Parts are painted, weighed, and then inspected a final time to check for fairness; a very smooth, aerodynamic finish is required because the part is a key flight component. Tracking weight data helps confirm part consistency, ensuring that Cobham won’t inadvertently deliver parts that could negatively affect the aircraft’s flight characteristics. The final production activity is installation of hardware components that enable a small servo actuator to control the rudder. Finished parts are shipped to an intermediate processor who outfits the winglets with required electronics.

“Lean” leads to new contracts

The process streamlining and lean initiatives employed for winglet production have enabled Cobham to produce winglets more cost-effectively while meeting its customers’ schedule requirements, a real plus in the current economy. In turn, Insitu has awarded additional part contracts to Cobham, including the ScanEagle’s nose sensor housing, a more geometrically complex, carbon/epoxy part. Concludes Zuieback, “We constantly explore ways to improve — mature manufacturing strategies can be made more efficient with good planning, good people and lean methods.”Related Content

Resins, additives, adhesives and 3D printing solutions

CAMX 2023: Arkema’s broad portfolio of products for composites fabricators aim to enhance performance, durability and sustainability.

Read MoreAdhesives, material solutions promote end market versatility

CAMX 2023: Rudolph Bros. and Co. highlights its role as a prominent specialty chemical distributor and solutions provider with a display of high-performance adhesives, sealants, materials and more from well-known manufacturers.

Read MoreHenkel releases digital tool for end-to-end product transparency

Quick and comprehensive carbon footprint reporting for about 58,000 of Henkel’s adhesives, sealants and functional coatings has been certified by TÜV Rheinland.

Read MorePontacol thermoplastic adhesive films are well-suited for composite preforms

Copolyester- and copolyamide-based adhesive films eliminate the need for sewing threads or binders when stacking laminates while improving the final part’s mechanical properties.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More