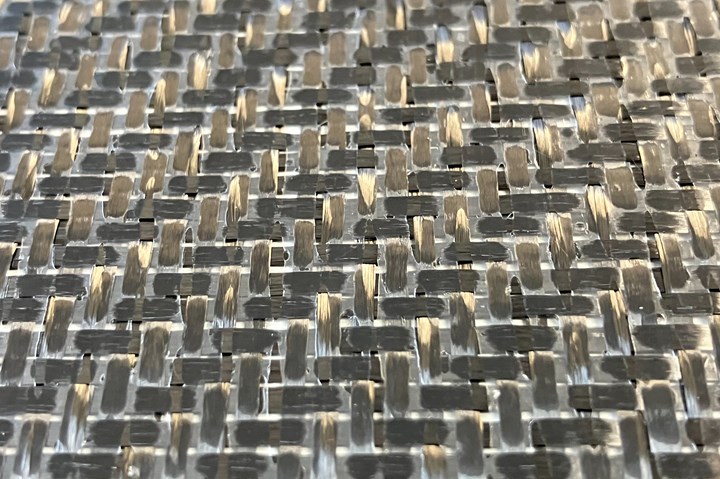

Pontacol thermoplastic adhesive films are well-suited for composite preforms

Copolyester- and copolyamide-based adhesive films eliminate the need for sewing threads or binders when stacking laminates while improving the final part’s mechanical properties.

Pontacol (Schmitten, Switzerland) highlights its thermoplastic adhesive films, ideally suited for the production of preforms and/or to improve the mechanical properties of finished composite parts.

The copolyester- and copolyamide-based adhesive films support the production of fiber-reinforced duromer composite components. Individual fibers/layers are laminated with the slit adhesive film, creating a fixation of the dry fiber fabrics or scrims, which Pontacol says ensures a specified fiber orientation for further manufacturing.

With minimal use of materials, an easy-to-use adhesive film eliminates the need for sewing threads or binders in liquid or powder form. The coated fiber cuts can then be reliably stacked into 2D preforms and, due to their thermoplastic properties, connected to one another by temperature or formed into 3D components. The produced preform is suitable for all common resin infusion processes. The resin (e.g., epoxy resin 1500 mPas) is introduced by vacuum or pressure (RTM).

The properties of the adhesive films, which are tailored to the matrix properties, enable an optimal bond between duromer and thermoplastic. In addition to the advantages of simple and efficient production of preforms, the mechanical properties of fiber--reinforced composites are also enhanced. In particular, the service life and susceptibility to damage are said to be improved through increased impact strength and the components can withstand higher mechanical loads.

Related Content

-

Film adhesive enables high-temperature bonding

CAMX 2024: Aeroadhere FAE-350-1, Park Aerospace’s curing modified epoxy, offers high toughness with elevated temperature performance when used in primary and secondary aerospace structures.

-

Park Aerospace launches aerospace, MRO structural film adhesive

Aeroadhere FAE-350-1 is a curing epoxy formulation designed for composite, metal, honeycomb and hybrid applications.

-

Henkel receives Airbus qualification for European aerospace manufacturing facility

The adhesive company’s Montornès, Spain, plant has been approved as a standard and raw materials supplier for various Airbus platforms, adding to its work in lightweighting, fuel efficiency and automation.