Powered by light weight vs. motors and batteries

CFRP specialist Uchida has developed the C-FREX exoskeleton, enabling mobility for people with spinal cord injuries. Replacing metal frame elements and powered motors with a novel, lightweight design, C-FREX uses CFRP and its elastic properties to help wearers walk more naturally without moving their legs. Source for all images | Uchida Carbon Composite Technology

The development and use of exoskeletons is growing. Dozens of manufacturers worldwide are developing/producing models, with at least five approved by the Federal Drug Administration (FDA, Washington, D.C., U.S.) to rehabilitate patients with neuromuscular conditions such as spinal cord injury and paralysis due to stroke. However, challenges remain. Engineers not only struggle with how to reduce cost — e.g., $60,000-$150,000 for powered lower limb models that enable walking — but also with how to supply sufficient power, ensure joint flexibility, decrease weight and make exoskeletons easier to customize and thus easier for wearers to adapt to.

Among the companies developing exoskeletons is Uchida Carbon Composite Technology (Saitama, Japan). Its product, C-FREX, is worn by and supports the lower body of patients who cannot walk independently. “It also changes the center-of-gravity movement of the upper body into a force that kicks the foot forward,” explains Katsuyuki Hara, technology development researcher and C-FREX developer at Uchida Carbon Composite Technology. “Thus, even patients who cannot actively move their lower body can perform walking rehabilitation without moving their legs. This counteracts the attenuation, or weakening, of their lower body muscles.”

The C-FREX bipedal (by means of two legs) walker was designed to help people with spinal cord injuries maintain their physical abilities, says Hara. “Our goal is to enable them to move around much like a healthy person without using any outside motorized power.”

C-FREX does empower its wearer, though not by using heavy motors or battery packs. Instead, it exploits the strength, stiffness and light weight of carbon fiber-reinforced plastic (CFRP) components — C-FREX weighs roughly 8 kilograms compared to powered models that weigh 20-24 kilograms. Most exoskeletons also use metallic components. “Having a long expertise in CFRP, we thought to apply it to specific parts of the device to reduce weight and activate elastic energy,” says Hara. CFRP’s elastic potential energy, discussed in more detail below, is key to the C-FREX design and well understood by Uchida, thanks to decades of working with a wide range of composite structures.

Expertise in CFRP

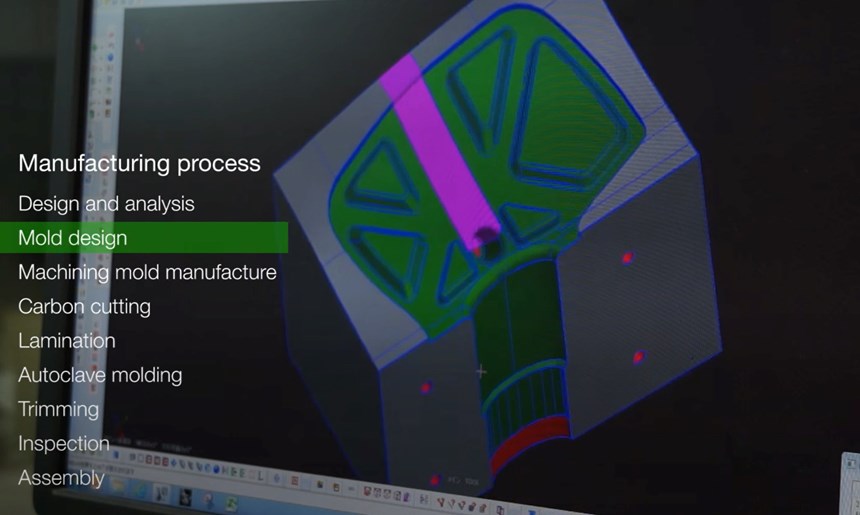

Uchida Carbon Composite Technology was founded as Uchida Kougei, making glass fiber-reinforced plastic (GFRP) mannequins for department stores in 1968. In 1980, the company began producing aerodynamic racing cowls for a leading Japanese motorcycle manufacturer. The customer later requested prototypes made using CFRP, which led to Uchida becoming an official partner of Honda Racing Corp. (HRC, Saitama, Japan).

Uchida then expanded into CFRP automotive parts, and then into aerospace by 1991. The company installed its first autoclave in 1999. By 2003, it had installed two more autoclaves and a second cleanroom. It built a new factory in 2007 and by 2014 was a supplier and/or development partner for companies including Volkswagen-Audi (Wolfsburg, Germay), AgustaWestland (now Leonardo, Rome, Italy) and IHI Aerospace (Tokyo, Japan).

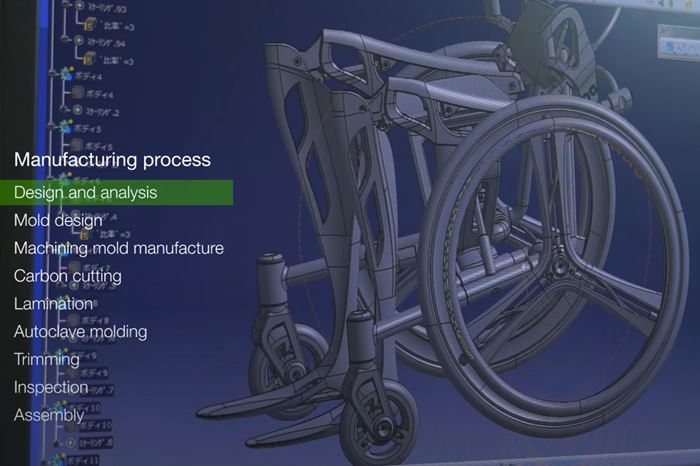

Five years ago, Uchida began development of C-FREX with Dr. Noritaka Kawashima at the Research Institute of the National Rehabilitation Center for Persons with Disabilities (NRCD, Saitama, Japan) and industrial designer Tetsuya Konishi of exiii Inc. (Tokyo, Japan). “We started in 2015 with a wheelchair and walking braces using CFRP and developed this into an integrated mobility device,” says Hara. The C-FREX Lightweight Composite Bipedal Walker won the 2016 JEC Innovation Award in the Better Living category. Uchida has continued to develop and refine the design, adopting a variety of materials.

Using CFRP’s stiffness and elastic properties

The C-FREX team began with an ARGO (advanced reciprocating gait orthosis) structure, a powerless orthotic device developed in the 1990s. The first reciprocating gait orthosis (RGO) devices were introduced in the 1960s. They join two knee–ankle–foot orthoses to a trunk corset, coupling the hip joints with cables in tension so that forces from extending one leg are transmitted to the other leg, assisting hip flexion when stepping forward. Numerous variations were developed, with the advanced reciprocating gait orthosis (ARGO) employing a single push-pull cable system in the pelvic section to assist walking performance.

Alhough the C-FREX frame’s structure allows the wearer to swing one leg forward using his/her upper body, like most ARGO devices, Uchida devised a shape which would make this process easier. “It is derived from an archery bow,” Hara explains. “We sought to meet user needs through a more sophisticated design not seen in other equipment.”

High-performance archery bows use CFRP to lighten and stiffen the riser (the midsection containing the grip) while making the upper and lower limbs more flexible, and thus able to bend more when the bowstring is extended. This increases the energy transferred to the arrow when the bowstring is released. C-FREX similarly uses CFRP to lighten and strengthen the exoskeleton frame while making the footplates more elastic. As with most RGO and ARGO devices, forearm crutches are still used in conjuction with C-FREX to provide balance during walking.

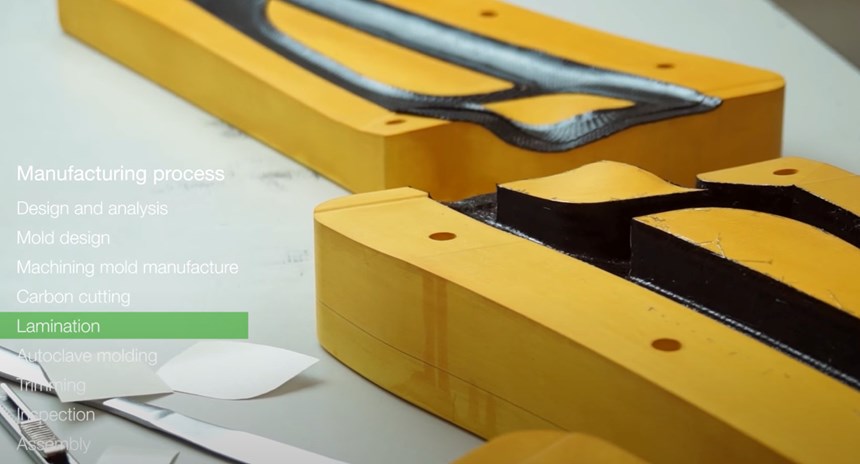

“The C-FREX design addresses the heaviness and weakness of current equipment,” says Hara. “It uses carbon material at the thigh in order to transmit power with a more natural movement, while the elasticity of the CFRP material also makes it easier to deliver the foot. We activate the elastic energy using the spring in the foot's CFRP plate to get a forward thrust that previous polycarbonate plastics could not produce.” Polycarbonate has been used on other, more conventional RGO and orthotic devices due to its toughness and ability to be reshaped. Uchida, however, has used its know-how in processing autoclave-cured prepreg to create thin CFRP shapes that are tailored, depending on location, for strength, stiffness and elastic properties.

“From 2017 to 2018, we developed knee joint flexion using an extension mechanism,” he continues. “Because the knee joint is fixedin conventional equipment, it is difficult to preserve sufficient clearance between the foot and the floor, which restricts movement and becomes a physical burden.” The knee joint is fixed because C-FREX users are patients with spinal cord injury and complete paralysis; they cannot stand. The fixed joint provides stability to stand. The C-FREX knee joint, however, can bend and stretch as it aligns to the walking cycle, notes Hara, which allows the stiff-legged walking mechanism characteristic of RGO and ARGO devices, but with an improved, more natural, less physically stressful gait.

Fig. 1. 3D printed CFRP

Parts comprising the knee joint and supporting the thighs (top) were switched from prepreg to 3D printed continuous carbon fiber-reinforced nylon using a Mark Two desktop printer from Markforged (bottom).

This knee is 3D printed with continuous carbon fiber-reinforced nylon using a Markforged (Watertown, Mass., U.S.) printer and uses metal components to complete the joint mechanism. Parts supporting the thighs were also 3D printed. “These were switched away from prepreg because they need to be tailored long or short to suit each user,” Hara explains. “The lower leg sockets and footplates, however, do not change much and thus can remain in prepreg.” C-FREX prototypes have used W-3101-A/Q-1120E 3K plain-weave carbon fiber/epoxy prepreg from Teijin Ltd. (Chiyoda-ku, Tokyo, Japan).

In addition to the CFRP and metal components, a system of cables and cams connects the knee of one leg through the hip joint, around the back and down to the hip and knee joints of the other leg. This patent-pending, original design modulates knee joint movement to achieve coordinated hip-knee motion. C-FREX components are assembled using adhesive bonding or mechanical fasteners.

Novel design for daily life, future mobility

Fig. 2. Wheelchair convertible

C-FREX can be used as a wheelchair by bending the knees and connecting it to a dedicated wheelchair unit. The user can dock and undock from the chair, aiding mobility in everyday activities, helping to counteract typical weakening of lower limb muscles.

C-FREX is also wheelchair convertible. “It can be used as a wheelchair by bending the knees of the main frame structure and connecting it to a dedicated wheelchair unit,” Hara explains. "Our goal is to provide an opportunity to walk for persons with Spinal cord injury."

He notes that the wheelchair provides mobility while C-FREX is a rehabilitation tool to preserve remaining nerve, muscle and circulatory function and improve overall health. Hara gives an example, “The user gets on the C-FREX wheelchair and goes to the hospital, then undocks from the wheelchair to use C-FREX for rehabilitation. Once finished, the user returns to the C-FREX wheelchair to go shopping and return home, etc. We are developing a device that can be incorporated into the activities of daily life.”

Uchida has continued to develop C-FREX, improving the knee function to lock and unlock with proper mechanical control. It has also better integrated the joints with the exoskeleton, again with the goal of making walking easier, notes Hara. Uchida exhibited C-FREX at the international REHACARE 2019 event (Sep 18-21, Düsseldorf, Germany) and the Consumer Electronics Show CES 2020 (Jan 7-10, Las Vegas, Nev., U.S.), with good response. Having already shown good results in testing at Japan’s National Rehabilitation Center for Persons with Disabilities, C-FREX is currently in gait testing; durability testing will be completed later this year. Uchida then plans to make C-FREX commercially available first in Japan, and then will consider European and U.S. markets. Though its price is still being finalized, Hara notes it will cost much less than powered exoskeletons currently on the market.

Related Content

Precision blades support industrial fiber cutting needs

CAMX 2024: Machine knives and industrial razor blades supplier American Cutting Edge offers composites manufacturers staple and custom cutting options.

Read MoreAerospace manufacturer meets increased demand with Plataine

Plataine’s AI-based solution, incorporated into the composite aerostructure manufacturer’s cutting and kitting operations, increased production throughput, material use, improved quality and reduced errors.

Read MoreInnoptus Solar Team uses Jetcam software to optimize production of solar vehicle

The world title-holding, Belgium racing team is producing its tenth composites-intensive solar car using Jetcam Expert nesting software.

Read MoreCompcut features ACS, PCR composite cutting technologies

Advanced plate saw and precision router provide precise, fast and efficient cutting of composite test specimens.

Read MoreRead Next

CFRP: Opportunities in orthopedics

Carbon fiber has a niche, but can it secure a larger piece of a high-growth pie?

Read MoreComposites in exoskeletons

Wearable robotics need strength, stiffness and lightweight and are forecast at a CAGR of 40-50%. Will composites play a role or be left behind?

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More