CAMX 2016 Show Report

The 3rd annual joint ACMA/SAMPE-sponsored trade event comes to Anaheim with an exhibition and conference program attractive to professionals across the composites world.

- Wind/Energy

- Cutting/Kitting

- Sustainability

- Automotive

- IACMI

- Sheet Molding Compound

- Pultrusion

- Defense

- Carbon Fibers

- Biomaterials

- Out of Autoclave

- Workforce Development

- NDI

- Machining/Drilling

- Materials

- Glass Fibers

- Fabrics/Preforms

- Pressure Vessels

- Adhesives

- ATL/AFP

- Weaving

- Consumer

- Processes

- Epoxies

- Resins

- Thermoplastics

- Aerospace

- Natural Fibers

- Mass Transit

- Reinforcements

- Markets

- Marine

- Injection/Overmolding

- Autoclave

- Construction

- Hi-Temp Resins

- Compression Molding

- Additive Manufacturing

- Prepregs

- Nanomaterials

- RTM

- Curing

- Infusion

- BMI

- Core

- Filament Winding

Share

In three short years, the Composites and Advanced Materials Expo (CAMX) has evolved into the largest composites event in North America, the composites industry’s largest market. CAMX officially kicked off on Sept. 27 with a General Session that featured three creative and visionary keynote speakers who have applied composites in new and compelling ways that promise to change how we think about communication, transportation and architecture. About 1,700 showgoers filled the hall to hear testimony of composites’ high utility as a problem-solving material.

Visionaries frame new futures

First up was Daniel Preston, CEO and CTO of Luminati Aerospace (Calverton, NY, US), a new company dedicated to bringing Internet connectivity to all areas of the world. He and his team are developing, among many products and technologies, high-altitude, long-endurance (HALE) unmanned vehicles that will harvest energy from wind and sun to stay aloft. These vehicles will be constructed by automated layup methods, using carbon fiber composites supplied by Hexcel (Stamford, CT, US).

Due to a scheduling conflict, Preston could not attend CAMX in person, but appeared via video. He commented on his early success as a student (college at age 12, graduated in his teens) and in business (sold his first business and “retired” in his 20s), and how that led, eventually, to the HALE effort, which was prompted by a “large dot-com” that was seeking to provide Internet access to underserved regions around the world. The result is the V0-Substrata, a solar- and wind-powered, pilot-optional, composite aircraft that, Luminati hopes, will be doing HALE-based work soon.

Next up was Gregory Haye, general manager at Local Motors (Knoxville, TN, US), who is overseeing his company’s development of vehicles built from advanced materials via large-format additive manufacturing methods, with a goal of reducing negative impact on the environment.

Haye walked session attendees through the implications of Local Motors’ “strive for less” mantra, the goal of which is to rethink the motor vehicle design-and-development paradigm. Or, as Haye put it, “The vehicle as we know it must die.” Haye emphasized Local Motors’ desire to condense the vehicle development process with digital-based tools that enable fast toolmaking and direct manufacturing — processes done via additive manufacturing technology; specifically, Cincinnati Inc.’s (Cincinnati, OH, US) Big Area Additive Manufacturing (BAAM) machine, which uses a chopped carbon fiber-reinforced ABS. Haye also discussed Local Motors’ work developing — in only three months — Olli, a composites-intensive, multi-passenger, autonomous mini-bus designed for urban mass-transit.

Wrapping up was Greg Lynn, owner of Greg Lynn FORM (Los Angeles, CA, US). At the forefront of fresh, functional and unusual structural design with composite materials, Lynn is one of the

10 most influential architects living today, according to Forbes magazine (see photo and caption).

Like Preston and Haye, Lynn is highly motivated to build new paradigms, based on the application of composites. In architecture, he noted, composites offer moldability and adaptability not possible with steel and aluminum. As a result, curved weight-bearing structures have become possible, bringing new dynamism to home and building design. The challenge, he said, is that many architects and designers are stuck in a paradigm that relies on legacy materials, and they are trying to adapt composites to fit into that mindset. “If you think about composite beams like you think about steel beams, it’s a mistake,” he said, adding, “In fact, if you think about composite beams at all, you’re lost.”

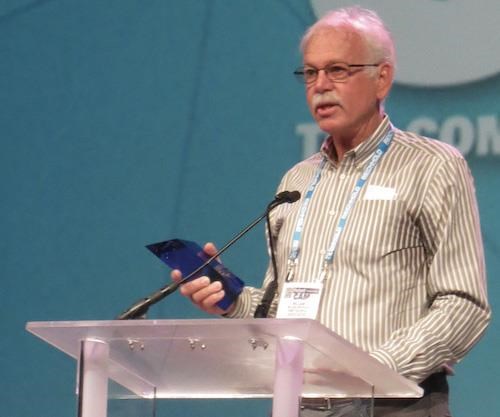

SAMPE distinguished service

Composites industry veteran Scott Beckwith received Society for the Advancement of Material and Process Engineering (SAMPE) inaugural Distinguished Service Award. The bequest came as a “complete and total surprise” to Beckwith, who said that he was overwhelmed by the honor.

Beckwith owns his own consulting firm, BTG Composites Inc. (Taylorsville, UT, US), and has been SAMPE’s technical director since 1998, making him the longest serving person on SAMPE’s executive board.

He says he joined SAMPE in 1974 when he got a job at Hercules in Salt Lake City, UT, US. Beckwith’s boss was a past-president of SAMPE and suggested Beckwith get involved. “Membership was just $26 a year, and I thought that was a pretty good deal,” he says. “Before I knew it, I was writing papers and giving presentations.” And he hasn’t looked back.

Looking to composites’ future, Beckwith is cautiously optimistic about growth and technical development. What he hopes to see more of, however, is technological cross-pollination, particularly between aerospace and automotive, the latter of which has substantial cycle time, quality and process-control problems to solve: “I am hoping that, as they meet those challenges and find solutions, the aerospace industry will adapt some of the same technology.” He also points to workforce development — particularly among high school and young college students — as vital to the composites industry’s expansion and maturation, and he is glad to see SAMPE and ACMA both heavily involved in education and training.

CAMX Awards

The winners of the annual Combined Strength, Unsurpassed Innovation CAMX Awards were announced at the CAMX 2016 General Session, and the prize-winning products hail from the fast-developing automotive and the architectural end-markets. The winner in the Combined Strength category was the “Multi- Material Decklid Concept,” submitted by Continental Structural Plastics (CSP, Auburn Hills, MI, US). The decklid, featuring a trademarked TCA Ultra Lite sheet molding compound (SMC) outer and a carbon fiber resin transfer molded (RTM) inner, weighs only 5.5 kg, representing a 13% weight savings over a similar aluminum decklid. When he received the award, CSP’s R&D director Mike Siwajek acknowledged that the material and process technologies in the decklid are not, technically, new, but emphasized that they have been combined in new ways to meet unique challenges. “By marrying all these technologies and making something old new again,” he contended, “we have a chance to really make an impact in the automotive industry.”

In the Unsurpassed Innovation category, the CAMX Award winner was “Fire-Resistant FRP Façade Cladding System for High-Rise Building,” submitted by Kreysler & Associates (American Canyon, CA, US). The cladding system, applied to the recent San Francisco Museum of Modern Art (SFMOMA, San Francisco, CA) expansion, marks the largest architectural use of fiber-reinforced plastic (FRP), to date, in a US building project. It required more than 700 panels, some as large as 1.5m wide by 9m long, totaling 7804m2 on a contoured 10-story façade, and was the first composite system to pass rigorous fire regulation testing for use above the fourth story.

Company president Bill Kreysler accepted the award but was quick to acknowledge his employees, who share the honor by having helped make the SFMOMA façade a reality. Kreysler also implored the audience to help accelerate composites development and application by getting involved with either ACMA or SAMPE. “You will make this organization stronger if you volunteer,” he said. “I always felt like I got more than I gave.”

Awards for Composites Excellence

ACMA also made its ACE (Awards for Composites Excellence) presentations in the pavilion by the same name on the CAMX show floor. ACE has recognized outstanding achievement and innovation in the categories of design, manufacturing and market growth/product development for more than 20 years. That tradition continued with the following announcements.

The winner in the Design category, Most Creative Application, was “Pultruded FRP Replaces Aluminum for the Silver Flow,” submitted by Strongwell (Bristol, VA, US), for an eye-catching car show display created for Mercedes. In the Manufacturing category, Material and Process Innovation, Oak Ridge National Laboratory (ORNL, Knoxville, TN, US) was selected for its “3D Printing of High-Temperature Thermoplastic Molds.” Elsewhere in the same category, T Plates Global LLC (Oceanside, CA, US) was a winner for Most Creative Application for its customizable thermoplastic sandwich core. Thermoplastic injection molded cells have an open architecture with strength in compression and shear and are welded (on one or both sides) to a 25-g/m2 nonwoven glass veil with random chopped fibers, suitable for large-area applications, such as wind turbine blades.

In the Manufacturing category, Equipment and Tooling Innovation, “Innovative Robotized Preform Cell Providing 3D Stacking and Control” was the winner, submitted by Composite Alliance Corp. (Dallas, TX, US). And finally, in the Market Growth category, Infinite Possibility for Market Growth, the winner is the “2017 Honda Ridgeline Weatherable SMC Truck Bed,” submitted by Ashland Performance Materials(Columbus, OH, US).

OOA innovation

In manufacturing and processing technologies, two technical presentations and a panel session featured out-of-autoclave (OOA) innovations — a relatively new trend with potential for aerospace-quality parts at lower cost. Demonstration of an inflatable, collapsible pressure intensifier for out-of-autoclave composite processing using BMI prepreg won an Outstanding Technical Paper Award. Steven Scarborough of ILC Dover (Frederica, DE, US) was the primary author and presenter; Steve Slaughter and Jason Varnum of Scaled Composites LLC (Mojave, CA, US) were co-authors.

ILC originally built the pressure intensifier for the US Department of Homeland Security as a 5.18m-diameter inflatable pressure tunnel for containing breathable air while sealed against poisonous gasses. Slaughter said he sees it, instead, as a big oven for curing composites. Scaled Composites has built all its aircraft without an autoclave — including the all-composite Voyager, which flew around the world nonstop in 1984, and SpaceShipOne, which won the Ansari XPRIZE in 2004.

Scaled fabricated 40.6-cm by 50.8-cm composite panels for cure at 15 psig pressure inside the pressure intensifier, using Toray T400-800 carbon fiber, with Solvay’s Cycom 5250-4HT BMI prepreg and AGY 6781 S2 fiberglass, with 5250-4 BMI prepreg systems. BMI resin was selected because it is more difficult to process by OOA than epoxy. The project produced an aerospace-grade laminate, i.e., <1% voids. Proposed applications include in-field aircraft repair and manufacture of wind blades.

Kara Storage, Air Force Research Laboratory (Wright-Patterson AFB, OH, US), moderated a Featured Session panel that considered OOA applications and their potential impact on growth. Panelists were Jim Martin (Globe Machine Manufacturing Co., Tacoma, WA, US); Randy Johnsen (Solvay Specialty Polymers, Tempe, AZ, US);

Doug Decker (Northrop Grumman, Falls Church, VA, US); Sean Johnson (TenCate Advanced Composites, Morgan Hill, CA, US); and Timotei Centea (M.C. Gill Composites Center, University of Southern California, San Diego, CA, US). Panelists agreed that new material systems need to be developed with good out-life and stability for OOA, and suitable for nondestructive inspection. Solvay and other suppliers are working on new resins and other materials targeted for OOA. OOA processes are seen as enablers for bonded structures, but some panelists suggested they might not be ready for large-aircraft manufacture.

Pilar Lopez (Airbus, Toulouse, France) presented her work in bonding primary and secondary structures on OOA bonded repairs for the A350 XWB. With a goal of certified OOA structural bonding repair solutions, she researched co-bonding possibilities using either dedicated repair materials or original product materials, with repair work done in portable cleanrooms or portable inflatable tent hangars. Two material grades have been qualified, and tests have shown that bonded repairs can be successful.

Bio-resin market growing

Sicomin Epoxy Systems (Marseille, France) presented its range of epoxy resins with a bio-based carbon content, ranging from 28-51%, which can be used in hand lamination, infusion, pultrusion/filament winding and HP-RTM processes. Sports equipment providers, from skis to surfboards, are pushing for bio-based products, says Sicomin’s export manager Marc Denjean. Sicomin’s bio-resin GreenPoxy33, for example, is being used to mold French ski manufacturer ZAG’s extra-light touring skis. And while several European companies have worked with the company to produce bio-friendly products, Marc Denjean says Sicomin also is seeing demand for the bio-resins in North American sports and leisure market.

Automotive crash analysis

Altair Engineering Inc. (Troy, MI, US) emphasized its tools and expertise for analyzing and optimizing composite structures. The company provides impact analysis for high-momentum events — bird strikes, crash impacts, drops and more — using its RADIOSS structural analysis solver. RADIOSS’ applications include not only crash safety, drop and blast, and hydrodynamic impact testing but also terminal ballistic fluid structural interaction, forming and composite mapping. Robert Yancey, Altair’s VP of aerospace, told CW that the company is using its 20-plus years of aerospace expe- rience to focus on automotive crash analysis to improve crashworthiness, safety and manufacturability of structural designs.

Polyamides for aircraft interiors

Solvay (Brussels, Belgium) announced at CAMX 2016 that its Ixef BM-1524 polyarylamide (PARA) is now qualified to the Boeing BMS 8-270 standard governing polyamides for aircraft interiors. This new listing expands opportunities for lightweighting through metal replacement for designers of aircraft interior components, and offers a more cost-effective, easily processed and structur- ally superior alternative to conventional plastics, such as poly- etherimide (PEI).

Armin Klesing, global business development manager for aerospace at Solvay’s Specialty Polymers business unit, says the newly listed product’s “unique mechanical and processing perfor- mance offers broader design latitudes for a wide range of aircraft interior components, which helped make its certification a priority for Boeing. Today, Ixef PARA is well-positioned to become the material of choice for commercial aircraft interior applications where cost-effective light-weighting is a key driver in polymer specification.”

A 50% glass-fiber reinforced, semi-crystalline, semi-aromatic polyamide, the natural-colored, halogen-free flame retardant (HFFR) polymer delivers metal-like strength and stiffness, making it an option for lightweight fasteners, attachments and brackets. Ixef BM-1524 PARA meets Federal Aviation Admin. (FAA) 60-second vertical burn requirements per 14 CFR 25.853 Appendix F, as well as toxic gas emission requirements under BSS7239 and ABD0031.

Reichhold + Polynt

As CAMX commenced, resins suppliers Reichhold LLC2 (Research Triangle Park, NC, US) and Polynt Composites (Carpentersville, IL, US) were in the midst of consummating a 50/50 merger that will, when complete, mark a substantial change in the composites industry’s resin supply chain.

Dale M. MacDonald, VP commercial, North America, at Reichhold, told CW that the merger has been approved by American regulatory authorities, but that European Union authorities were still reviewing the deal. The hope, he said, is that it would be is that it would be approved by year’s end.

Until then, how the merged companies might present themselves to the market remains to be seen. MacDonald says it’s undecided what will become of the Reichhold and Polynt names post-merger, but he did point out that the former celebrates its 90th anniversary in 2017.

On the composites process side of the business, MacDonald said it’s business as usual. He noted that Reichhold is working right now, in cooperation with the Institute for Advanced Composites Manufacturing Innovation (IACMI, Knoxville, TN, US), to apply its Advalite vinyl hybrid monomer-free resin to automotive struc- tures. It offers, he said, a cure time of 45-60 seconds and a Tg of 150°C, which makes it suitable for the electrophoretic (E-Coat) painting process.

Educational partnership

Composites One (Arlington Heights, IL, US) and Davis Applied Technology College (DATC, Kaysville, UT, US) announced an educational partnership designed to provide students with the skills needed for a successful career in the composites industry by helping students explore advanced composites, including prepreg, thermoplastics, out-of-autoclave processing and additive manufacturing.

Composites One president/COO Leon Garoufalis said, “With this new partnership, we can help prepare the next generation of composites professionals, as well as ensure that more of our industry’s existing workforce is educated on the latest composites technologies.”

“Where education and industry can come together with a common cause is always a productive partnership,” commented DATC president Michael Bouwhuis. “Together we will help to prepare highly skilled workers to preserve global competitiveness and economic opportunity within the composites industry. We will also ensure that there is a future workforce for this growing industry.”

Cure sensors

AvPro Inc. (Norman, OK, US) has partnered with TSI Technologies LLC (Wichita, KS, US) to develop the next generation of composite cure temperature sensors, called the ThermoPulse system. Consisting of an antenna with transmit and receive capabilities, an embeddable microwire temperature sensor and a reader box, which collects the antenna readings, the ThermoPulse in-situ measure- ment system allows for wireless monitoring of temperature from the interior of a composite part, bondline or repair.

Measuring just 0.25 mm by 32 mm, ThermoPulse sensors are small enough to be permanently embedded in fly-away parts. Studies with American and European companies showed no signifi- cant difference in mechanical properties between samples created with sensors and those without.

Throughout cure, the ThermoPulse Microwire supplies real-time temperature data to the controller, providing assurance and log records that performance-critical parts are actually reaching required temperatures.

On a similar subject, Christian Weimer, head of Domain Composite Materials & Process for Airbus Group Innovations (Munich, Germany), gave a presentation on Sept. 29, titled, “Increasing the Productivity of CFRP Production Processes.” Speaking mainly through the lens of increasing predictability and reliability, Weimer discussed current issues and future needs in composite aerostructures production. He then announced that Airbus has spun off a new subsidiary, InFactory Solutions (Ottobrunn, Germany), that will develop, qualify and deliver sensor systems, data analytics and engineering consulting services for more automated, connected and intelligent manufacturing.

InFactory’s first commercialization is a sensor for quality moni- toring during automated fiber placement (AFP) of composite structures that reduces inspection time by >95%. The sensor can be used on any AFP head (e.g., AFPT, Coriolis, Electroimpact, Fives, Ingersoll, MTorres) and is qualified per Airbus Process Spec (AIPS).

The system already is undergoing tests for A350 XWB production at the Airbus plant in Illescas, Spain. Sites in Germany, Airbus Group Helicopters in Donauworth and Premium Aerotec in Augsburg, will follow by year’s end.

Recycling collaboration

Connora Technologies (Hayward, CA, US) and Adesso Advanced Materials (Wuxi, Jiangsu Province, China and Monmouth Junction, NJ, US) revealed recent steps taken to advance their recyclable epoxy technology. Connora exhibited its Zero-landfill Manufacturing Project with Burton Snowboards (Burlington, VT, US) and the world’s first recyclable surfboard. The project involves not only recovering fiber but converting reclaimed thermoset epoxy into a thermoplastic, which is then reused in snowboard bindings and surfboard fins. Meanwhile, Adesso displayed printed circuit boards that are similarly recyclable, addressing a huge issue for the electronics industry, as well as programs with composite bicycle manufacturers and electric bus suppliers/operators.

COUNTERVAIL in a racket

Materials Sciences Corp. (MSC, Horsham, PA and Greenville, SC, US) and Wilson Sporting Goods (Chicago, IL, US) have entered into an exclusive agreement to explore and develop applications of MSC’s COUNTERVAIL vibration-damping composite technology. MSC exhibited the 2017 Serena Williams Blade SW 104 Autograph racket, which uses COUNTERVAIL to reduce vibration energy, helping players experience better control and less fatigue, without sacrificing light weight, stiffness or feel.

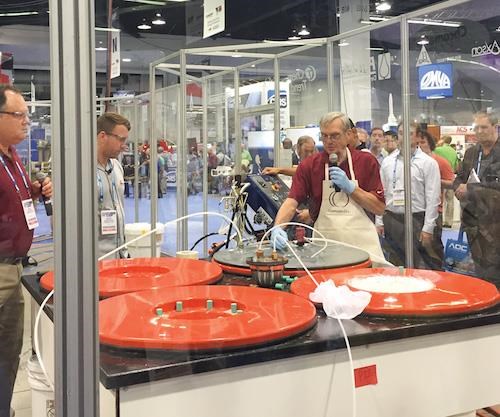

Exhibition quick takes

- Compotool (Monroe, WA, US) displayed high-temperature tooling materials and ceramic tooling board that can be vacuum bagged and autoclave cured, and reported significantly reduced manufacturing time.

- Dexmet Corp. (Wallingford, CT, US) had lightning strike foils thinned down to 0.001-0.002 inch from existing 0.003-0.005 inch.

- Evonik Foams Inc. - ROHACELL (Theodore, AL, US) showed off its PMI Triple F Rohacell foam cores for carbon composites — a closed cell, high- temperature-resistant structural material developed primarily for automotive products and found in some Lamborghini sports car models.

- McClean Anderson LLC (Schofield, WI, US) featured its new Pattern Master III entry-level software controls for axial and off-axial filament winding, for mass manufacturing of pipes.

- MISTRAS Group(Princeton Junction, NJ, US) showed NDI equip- ment for water-immersion or air-coupled, through-transmission inspection, plus passive acoustic emissions systems for infra- structure and aerospace.

- NDT Solutions (New Richmond, WI, US) partnered with a Tier 1 supplier to manufacture composite hat-section stringer- stiffeners for wingskins. NDT pulse-echo ultrasonic inspec- tion allows 100% inspection, in two passes, of the top, sides and radius of the composite cured stringer.

- Quatro Composites (Orange City, IA, US) featured QFORGE chopped carbon/PPS with 0.5-inch to 1-inch (12.7-25.4-mm) long fiber in a proprietary thermoplastics molding process, said to be 30-40% lighter than aluminum, but at a similar cost.

- Sigmatex (Benicia, CA, US), introduced 3D fabrics with no seams, joints or overlaps — a single-piece, woven fabric in x, y, z directions that can be custom-preformed by CAD design in fiber architecture for near-net shape by matched die molding, RTM or RIM. It has also added spread-tow fabrics for automotive and sporting goods. Also, recycled fabrics made from the waste streams of carbon fiber can be aligned with thermoplastics into new fabric. The result is said to be similar in level to virgin-grade fabric with thermoplastic blend. Main market is automotive.

Related Content

Sunreef Yachts completes 43-meter single-shot hull infusion project

Sunreef 43M Eco electric catamaran, with a composite surface of 1,700 square meters, is considered to have the world’s largest infused hull.

Read MoreEngine vane demonstrates potential for gapped, unidirectional dry fiber for infusion

GKN Aerospace and its partners developed an aircraft demonstrator component made with TeXtreme’s latest Gapped UD material, proving out a dry, infusible tape meant to compare in performance to UD prepreg.

Read MoreAmpliTex-constructed solar-powered ferry hits the Adriatic Sea

The Marservis PROeco is a mass transportation marine vessel using Bcomp natural fiber for interior parts in place of standard materials.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More