Composite-cored conductors: Holding the line

After a decade of incremental inroads, two different composite-cored electric power transmission products are connecting with those who specify for the grid.

Thermal sag is often responsible for causing grid outages on electrical transmission and distribution (T&D) lines. It happens when the current running through an electrical conductor cable exceeds the cable’s transmission capacity and overheats the wire. In a traditional bare Aluminum Conductor Steel Reinforced (ACSR) overhead conductor, the high coefficient of thermal expansion (CTE) of the aluminum wire-wrapped cable’s steel strength member or core (11.5 x 10-6/°C) causes it to elongate and sag at relatively low temperatures. As the cable sags, it has the potential to violate minimum ground clearance limits, which can cause electrical arcing, short circuits and cascading outages. Thermal sag conributed to the 2003 blackout on the U.S. East Coast and might have been a factor in the devastating July/August 2012 blackout in India. Utility companies are seeking solutions.

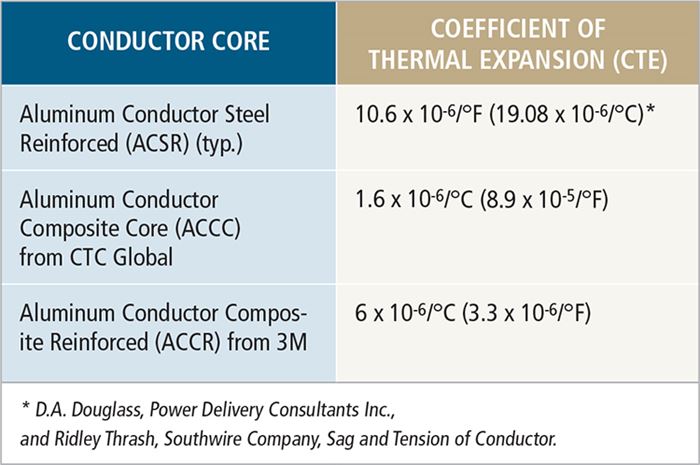

One solution is to install additional cable lines. But this is a costly option, involving not only more installation time and labor but also the need to secure new rights of way and the various permits from local regulatory agencies. A better option is to upgrade existing lines with High-Temperature Low-Sag (HTLS) conductors, which hold their shape better at higher temperatures because they exhibit much more favorable CTEs (see Fig. 1).

Two U.S. companies have developed HTLS conductors for this $1 billion-plus business — a subset of the overall electricity transmission market valued at about $50 billion — using load-bearing composite cores with substantially lower CTEs than traditional ACSRs. (Read more about HTLS technology in “Composites connect with the world of cabling,” under "Editor's Picks," at top right.) In each conductor, the uniquely fashioned composite core increases the amp capacity (the electricity capacity of the cable, measured in amperes — ampacity, for short) that the transmission line can carry before it begins to sag. Both companies have seen dramatic growth since they came on the market and utilities worldwide have discovered the value they offer.

Aluminum Composite Core Conductors

CTC Global in Irvine, Calif., has experienced exponential growth of its hybrid carbon/glass fiber Aluminum Composite Core Conductors (ACCCs) since its inception in 2002. The cable’s composite core has a CTE of 1.6 x 10-6/°C, a small fraction of the CTE seen in steel-cored cables, with correspondingly smaller potential for sag. Moreover, ACCCs can operate continuously at 356°F/180°C with peaks up to 392°F/200°C. In 2006 the company had installed eight ACCCs for field testing and had upgraded one 6.7-mile/10.8-km section of power line in Utah. Six years later, as of September 2012, the company had installed more than 9,200 miles/14,806 km of ACCC conductor wire in more than 220 projects worldwide — and it has many more orders in its pocket. One order alone, with American Electric Power (Columbus, Ohio), will provide 1,665 miles/2,680 km of ACCC wire for a 345-kV reconductoring project in Texas, involving about 555 miles/893 km of power line. (Note: The actual cable length in a power line can vary. The U.S., for example, typically uses alternating current, which generally requires three conductors per line, so 60 miles/96.6 km of conductors would be needed for a typical 20-mile/32.2-km power line.)

CTC’s director of technology Dave Bryant says CTC has installed projects in such varied locations as “mountain ranges in China, deserts in Qatar and even virtual war zones.” In 2009 the company installed 430 kcmil (218 mm2) ACCC conductors with diameters of 0.720 inch/18 mm to replace very old copper conductors in Nevada on a 20-mile/32-km, 69-kV line (Fig. 2) that runs from Reno to Carson City. (The abbreviation kcmil stands for thousand circular mil. A circular mil is the cross-sectional area of a cable with a diameter of 1 mil. One kcmil equals 0.5067 mm2.)

The line runs, by turns, through land managed by the U.S. Bureau of Land Management, privately owned property and environmentally sensitive areas. Installing new lines would have required lengthy permitting processes in all three cases. Instead, the use of lightweight ACCC HTLS conductors made it possible to upgrade the line on the existing right of way to accommodate capacity for emergency conditions. It’s a good thing, too. Two years later, winds exceeding 100 mph/260 kmh thrashed the area, and the following year a firestorm destroyed nearly 40 houses and burned to the ground several of the wooden H-frames that carry the cable. “The conductor fell to the ground during the fire, but, remarkably, it wasn’t damaged,” Bryant says. “So they were able to simply replace the H-frames, put the wire back in the air and re-energize the line very quickly.”

The company’s technology has remained basically the same since 2006. A hybrid carbon/glass fiber core is produced by pultruding carbon fibers with a glass fiber overlay in an epoxy matrix, through a dedicated steel die at temperatures as high as 500°F/260°C. The glass overlay creates a barrier between the carbon fiber and the aluminum conductor, preventing galvanic corrosion. Sufficient fibers are loaded onto supply reels to continuously produce the core, without any fiber splicing, in the length specified by the customer — typically in 2-mile/3-km sections.

CTC has multiple qualified suppliers for composite materials, but typically it uses carbon fibers from Toray Carbon Fibers America (Flower Mound, Texas) and boron-free E-glass fibers from Owens Corning (Toledo, Ohio), with a proprietary epoxy resin system. Bryant says 1 ft/305 mm of a 0.375-inch/9.5-mm diameter core uses about 0.10 lb/0.45 kg of fiberglass, carbon and resin. CTC’s 9,200 miles of cable required about 4,857,600 lb (2,203,368 kg) of composite material.

The core is wound on dedicated reels as it comes off the machine and is then rewound onto shipping reels. As it is rewound, the core is led through a series of pulleys to test its bending capabilities. The core reel is then sent to one of CTC’s 10 ISO-certified stranding partners and is helically overwound to CTC specifications with high-quality trapezoidal-shaped aluminum strands (trap wire, see Fig. 3a & 3b).

“The ACCC conductor has been type registered or approved for use and installed in 24 countries worldwide,” Bryant says, “and most recently in Russia.”

Aluminum Conductor Composite Reinforced cables

3M’s Electrical Markets Div. in Austin, Texas, also has seen widespread acceptance of its HTLS conductors. 3M’s Aluminum Conductor Composite Reinforced (ACCR) cable, which makes use of a metal-matrix composite core with a CTE half that of steel (6 x 10-6/°C), now has about 1,600 miles/2,575 km of conductors in some 13 countries, covering all continents except Australia and Antarctica, according to Kay Gehring, marketing manager for 3M’s Electrical Markets Div. The company is in the process of doubling its manufacturing capacity at its plant in Menomonie, Wis., in response to demand.

To date, 3M has manufactured a full line of trap wire in 267 to 1,622 kcmil (135 to 828 mm2), using its own materials. The process starts with an alumina ceramic oxide (Al2O3) powder that is made into a gel. The gel is extruded through spinnerets to form fibers that are then imbedded in high purity aluminum to make the core wires. Tens of thousands of fibers run continuously in axial (0°) orientation through the core wire. Based on the customer size/strength requirements, 7 to 19 core wires are stranded together in a conventional twisted cable, with an overwrap of continuous aluminum zirconium (Al-Zr) strands. Although the core wires can be operated at much higher temperatures, the Al-Zr strands permit continuous operation at 410°F/210°C with peaks up to 464°F/240°C.

In July 2012, EDP Escelsa (São Paulo, Brazil) selected ACCR cables as replacements on power lines that were sagging dangerously close to seasonally high water on the Rio Doce River in Linhares. EDP replaced conventional ACSR with ACCR conductors on the 3,012-ft/918m span. This doubled the 138-kV line’s ampacity and improved line clearance without new construction or the need to obtain new rights of way.

In another project, Georgia Power (Atlanta, Ga.), estimates that $15 million to $20 million was saved by using ACCR to upgrade 34 miles/54.7 km of 230-kV power transmission line that serves the nearby city of Savannah (see Fig. 4). Georgia Power knew there were some environmentally sensitive areas along the transmission line’s existing route where an attempt to acquire additional rights of way would be a practical impossibility. Gehring says “They used the biggest conductor, the 1,622-kcmil diameter trap wire,” and scheduled construction outages on the line only during low-demand periods — specifically 10 weeks in the fall and 10 weeks in the spring through 2011 and 2012.

Beyond acceptance

Composite-cored HTLS conductors have not only been accepted but also have established a rapidly growing presence in the overheating power market. So far, these new brands have conformed to standards for steel-core conductors. But industry leaders are working with ASTM, ANSI and others to create new standards specifically focused on HTLS conductors.

Related Content

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreSwedish parking garage to incorporate decommissioned wind blades

Architect Jonas Lloyd is working with Vattenfall to design the multistory building with a wind blade façade, targeting eco-friendly buildings and creative ways to remove blades from landfills.

Read MoreComposites reinvent infrastructure

Celebrating National Composites Week, CW shares ways in which composites continue to evolve the way we approach infrastructure projects.

Read MoreGatorbar, NEG, ExxonMobil join forces for composite rebar

ExxonMobil’s Materia Proxima polyolefin thermoset resin systems and glass fiber from NEG-US is used to produce GatorBar, an industry-leading, glass fiber-reinforced composite rebar (GFRP).

Read MoreRead Next

Composites connect with the world of cabling

Composite cables prove they can handle high tension - on land, over water and under the sea.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More