Composite flywheels: Finally picking up speed?

A wave of new composite flywheel developments for bus, rail, auto, heavy truck, construction equipment, and power grid support promises fuel savings, improved efficiency and reduced emissions — i.e. sustainability in the global quest for more energy.

Go-Ahead Group has outfitted six London buses with composite flywheels from Williams Hybrid Power, modified from reliable, performance systems used in Formula 1 racing.

SOURCE: (left) Go-Ahead Group, plc and (right) Williams Hybrid Power.

Composites in Flywheels

Flywheels have been used for thousands of years (e.g., in pottery wheels) and are still used in piston engines today. The basic design of a flywheel is a disk that rotates, sometimes at very high speeds, using conservation of energy to store surges from a power system and then release that power back as needed.

In the 1950s and 60s, flywheels were used on buses in Switzerland, but they were heavy, prone to explosive failure and had no way of compensating for the angular momentum that made turning difficult. Composites have played a large part in solving these issues.

In the 1960s, Urenco (Buckinghamshire, U.K.) developed a flywheel that used composite materials to make the disk, or rotor, much lighter and replaced stationary magnets with a magnetically loaded composite (MLC) made from glass fiber impregnated with magnetic powder. (See “Composite Flywheel: HEV racing dynamo” in Dec 2011 CT). The MLC eliminates eddy current losses, boosting storage efficiency to 97 percent, while carbon fiber has significantly increased rotor tensile strength.

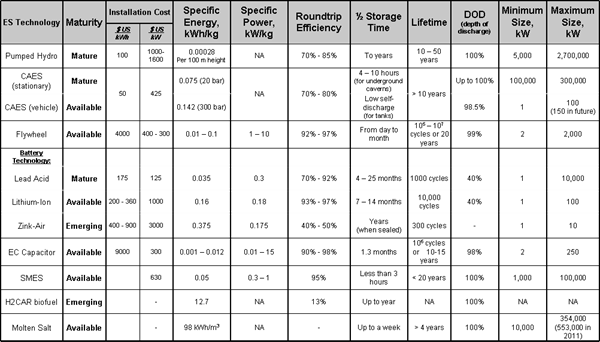

Energy Storage Systems Table by Ricardo plc

All-composite rotors — versus steel hub and composite overlay — offer lighter weight and reportedly improve safety. The lighter weight also improves energy storage, as POWERTHRU explains: “Kinetic energy is roughly equal to mass times velocity squared. So doubling mass doubles energy storage, but doubling the rotational speed quadruples energy storage.” Thus, today’s all-composite rotors allow faster rotational speed (40,000 to 60,000 rpm), which increases short-term energy storage capacity.

Composite construction has also helped ensure safety via optimized containment and rotor designs that are less prone to fail, but when they do, can be completely contained. Finally, gimbals are now used to counteract angular momentum effects. As the CT article describes, Urenco's composite flywheel technology was modified by the Williams Formula 1 motorsports team and then spun off as Williams Hybrid Power (WHP, Oxfordshire, U.K). Many other companies have also now entered the market.

Composite Flywheels in Use

There are two main forms of equipment: mobile systems for cars, trucks, construction equipment and light rail trams, and stationary units used to support mass transit rail systems and power grids.

Mobile Systems

For cars, trucks and construction equipment, the flywheel is typically coupled with a continuously variable transmission (CVT) or hybrid transmission by electrical cables. During braking, electricity is generated by an electric traction motor at the axles, which travels through the cables to charge the flywheel, spinning it up to 40,000 rpm or higher. Then, when the vehicle accelerates, the system works in reverse, so that less energy is needed from the combustion engine or from an electric/hybrid vehicle’s batteries. Energy/fuel savings can be as much as 40 percent, and CO2 emissions are also cut significantly. Thus, the more a vehicle stops and starts, the better its fuel efficiency, and, unlike a battery, a flywheel never loses its ability to charge and discharge energy.

Bus

For buses, WHP reports that a single flywheel, smaller than a spare tire, can reduce fuel costs by 15 to 40 percent, with an installation that is relatively easy and cost-effective. Flywheel bus programs and suppliers include:

- WHP won the 2013 Low Carbon Champion Award for its program with partner Go-Ahead Group (Newcastle upon Tyne, U.K. – for link, scroll down to Flywheel Buses) — which claims to be London’s largest bus operator with a fleet of 4,600 buses — to retrofit six buses with flywheel technology aimed at a 20 percent increase in fuel efficiency.

- GKN-Evo

- Flybus program: Ricardo, Torotrak, Optare

Auto and Truck

- Audi won the 24 Hours of Le Mans race in 2013 for the second consecutive year with the R18 e-tron quattro, supported by WHP flywheel energy storage technology. The hybrid racecar ran for 24 hours without any technical problems in difficult, wet conditions, demonstrating the robustness of its hybrid system. This adds to the one-two victory in the 2012 race, where the R18 e-tron quattro became the first ever hybrid vehicle to finish on the podium.

- Volvo is testing an experimental flywheel-based kinetic energy recovery system (KERS) on a turbocharged four-cylinder Volvo S60 that adds up to 80 horsepower, the same as adding two more cylinders, but with 25 percent better fuel economy for a car that accelerates to 100 km/hr (62 mph) in 5.5 seconds.

Construction Equipment

- Ricardo (Shoreham-by-Sea, West Sussex, U.K.) launched its TorqStor high-speed flywheel energy storage unit at the CONEXPO 2014 show in Las Vegas on March 4. In a 17-tonne production excavator, TorqStor stores and re-uses roughly half of the total potential energy currently wasted in arm/bucket descent, reducing fuel burned by 10 percent.

- Hatch (Mississauga, Ont., Canada) has teamed with Williams F1 to develop new products and services for current and potential mining, energy, infrastructure and industrial clients. In presentations, it lists energy savings for mining equipment and remote location wind-diesel power generation systems as key targets.

Light Rail and Trams

- Even using a low-speed, steel flywheel, Parry People Movers (Cradley Heath, U.K.) was able to downsize the liquid natural gas (LNG)/propane-fueled internal combustion engines (ICE) for propulsion in two railcars from 14 liters to 2.3 liters and added regenerative braking. As a result of this 2011 project, the 10 metric ton vehicle’s fuel economy was increased seven to eight times versus previous diesel propulsion, while reducing CO2 emissions by more than 300 percent.

- WHP and Alstom Transport (Saint Ouen, France) have signed an agreement to put flywheel energy storage systems onto Alstom Citadis trams by 2014 with a goal of 15 percent fuel savings.

Stationary Systems

These include lineside systems for mass transit rail networks and electrical grid support, the latter including power output smoothing for wind-diesel and other hybrid renewable energy-based systems. Flywheel energy storage devices reduce the amount of diesel fuel needed in hybrid systems when the wind or other renewable energy output falls. They also reduce charge-discharge cycles for batteries, enabling them to be used as long-term bulk storage, which is their strength. This prolongs battery life and improves the network’s transient response (i.e. decreases the number of seconds-long power outages) and fault-clearing capability (each power loss, or fault, must be cleared before power can be restored).

Mass Transit and Rail Lineside

The Williams F1/Advanced Engineering website has a great video showing how stationary flywheel systems work in this application. Williams claims energy savings of up to 30 percent are possible in a typical metro application and reduced voltage and power demands on the electrical network could enable more trains during peak demand as well as prevention of costly network upgrades or else downgrading network demands to meet same peak capacity. Other rail flywheel projects and suppliers:

- Pentadyne Power Corporation (Los Angeles, Calif. - POWERTHRU acquired production assets in 2010) supplied a 2.4MW lineside system using carbon composite flywheels for the Long Island Rail Road (LIRR) Hempstead Line. A previous demonstration flywheel system was successfully tested on the Far Rockaway line in 2002.

- Vycon (Cerritios, Calif.) announced in November 2012 its award of a $3.6 million contract by the Los Angeles County Metropolitan Transportation Authority (LACMTA) to install a flywheel energy recovery system at the Red Line Westlake/MacArthur Park Station. Another flywheel system is planned for the Gold Line in Highland Park. Vycon discusses both steel and composite rotors but does not detail its “proprietary” construction. It is interesting to note that LACMTA’s 2013 Sustainable Rail Plan describes the high maintenance of flywheel systems. This may very well be due to Vycon’s use of steel vs. purely composite in its rotors.

Power Grid Support

- Beacon Power, LLC (Tyngsboro, Mass., USA) has emerged from bankruptcy in 2012, and is now backed by a private investment firm. It claims to be the world leader in grid-scale flywheel energy storage systems with two 20 MW energy storage facilities in operation, the first at Stephentown, N.Y. and the second in Hazle Township, Pa.

- WHP has installed stationary flywheel systems on Fair Isle and the Isle of Eigg in Scotland.

- ABB (Zurich, Switzerland) offers converters for flywheel energy systems citing, “These benefits compared to a battery include not being constrained by such tight temperature limits, no development of a charge memory, no lifetime degradation of performance, manufactured from inert materials and precise calculation of remaining charge.”

Lifetime

According to WHP director Patrick Head, there are 500,000 composite centrifuge rotors (used for enriching uranium) that have been operating 24/7 for 20 years. (Note: a quick analysis of Urenco enrichment facilities estimates 575,000 centrifuges in operation by 2020.) According to an in-house strategy document, Urenco claims, “Another huge strength that Urenco has is their centrifuge technology that runs for 35 years while competitors have to replace their machines every 12 to 15 years.” Williams claims that initial investment costs for its stationary flywheel systems — which are capable of 7 to 10 million deep charge-discharge cycles — are much lower than competitive energy storage systems that have much shorter service lives, namely ultracapacitors (≈1 million cycles) and batteries (≈10,000 cycles).

Battery Enabler

In its December 2011 report, “An Assessment of Flywheel High Power Energy Storage Technology for Hybrid Vehicles,” Oak Ridge National Laboratory (ORNL, Oak Ridge, Tenn.) compares the performance of flywheels and batteries and concludes, “the most effective utilization of flywheels is in providing high power while . . . just enough energy storage to accomplish the power assist mission effectively. . . . flywheels could be effectively utilized in conjunction with and complementary to batteries . . . can extend the life of batteries by allowing their charge and discharge to be less demanding and can even allow the batteries to be downsized and made less expensive to purchase and maintain.”

The Market

The report “Advanced Energy Storage Systems Market by Technology . . . Global Trends & Forecast to 2018” by MarketsandMarkets.com — which includes flywheels as well as pumped hydro, compressed air, batteries and supercapacitors, and is also split by grid storage and transportation applications — estimates an annual growth in excess of 16 percent, from more than $4 billion in 2012 to nearly $10 billion by 2018. There are many other estimates that predict higher numbers. For example, battery supplier Eos Energy (New York, N.Y.) predicts a global opportunity of $16 billion by 2016 for batteries in electric vehicles alone. Other projections for power grid devices are in the $33 billion range.

An article by Paul Tullis on slate.com outlines six qualities that an ideal energy storage solution would have:

- Store a lot of energy in a small space;

- Be inexpensive;

- Lose less than a fifth of the energy during transfer in and out of storage;

- Last decades;

- Release stored energy quickly.

- Be safe to transport and non-toxic to dispose of, as well as made of raw materials that can be obtained without causing major environmental damage.

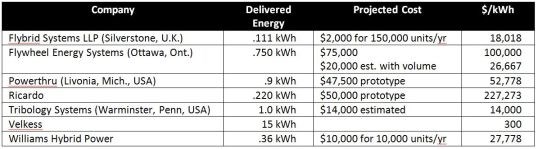

Flywheels actually deliver almost all of these, except for cost, which is still an issue. The table below shows projected cost figures given in the 2011 ORNL report with an additional line item for the Velkess flywheel, developed by Silicon Valley inventor, Bill Gray. He claims it can store electricity for $300,000/MWh, or what he says is about one-tenth the cost of comparable storage by Beacon Power. Gray says he reduced the cost of materials by using E-glass fiber instead of carbon fiber.

Interestingly, Boeing Research & Technology (Seattle, Wash., USA) showed a graph in a 2012 presentation targeting less than $100/kWh via a new proprietary fiber in the flywheel rotor material. Meanwhile, WHP’s Patrick Head says its materials cost $723.12 per unit and is targeting an annual production of 1,500 machines. However, it admits these small volumes keep unit cost high and for its next step in mass production a partner like GKN, Alstom or Siemens will be needed to achieve the necessary manufacturing efficiencies.

Will flywheels finally reach the tipping point? The market drivers for improved fuel efficiency, smart grids and more sustainable power networks are all supporting it, and the wave of players involved is mounting. Still, volume applications are needed. Perhaps if new lower cost composite rotors can indeed deliver performance and reliability, and manufacturing can be scaled sufficiently, flywheels will at last be able to deliver their energy potential en masse.

Other companies listed in the 2011 ORNL report:

- Active Power

- Caterpillar Flywheel UPS

- Powerware Flywheel UPS

- PCI (http://www.pciups.com/products.htm)

- CM Technololgy

- KST Rotary Solutions (http://kst-rs.com/index.htm)

- Precise Power Corporation (http://www.precisepwr.com)

- Flybrid Automotive Limited

- Flywheel Energy System Inc.

Related Content

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreMicrowave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More