Composite Piping On Hoover-Diana

EDO supplied a drain system for Hoover-Diana, a deep draft caisson vessel (DDCV) put into service in May 2000 by Exxon Mobil and British Petroleum. Hoover- Diana, located in the Gulf of Mexico’s East Breaks and Alaminos Canyon Blocks at a water depth of approximately 4,800 ft, is designated as a DDCV instead o

EDO supplied a drain system for Hoover-Diana, a deep draft caisson vessel (DDCV) put into service in May 2000 by Exxon Mobil and British Petroleum. Hoover- Diana, located in the Gulf of Mexico’s East Breaks and Alaminos Canyon Blocks at a water depth of approximately 4,800 ft, is designated as a DDCV instead of a spar vessel because it does not store oil, whereas a spar typically stores crude oil within its structure. Homogenously conductive resin was required to make the drain lines electrically conductive, because they run in and out of hazardous areas on Diana. EDO makes its own, proprietary conductive resin by adding carbon-based conductive material to its standard vinyl ester. Conductive resin is used for the fittings, flanges and joints as well as the pipe.

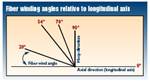

Working for Mustang Engineering (Houston, Texas, U.S.A.), EDO produced nearly 3 miles/4.6 km of FIBERBOND piping topside, along with over 2,000 fittings for Diana’s drain lines, fire ring main and seawater system. Piping for the Diana was manufactured using the standard 54° winding angle. Most of these assemblies were installed at Brown & Root’s Green Bayou fabrication facility near Houston. (Aker Maritime ASA, Oslo, Norway, designed the DDCV and Aker Rauma Offshore handled the hull fabrication work in the Aker Mantyluoto facility in Pori, Finland.)

On the Nansen and Boomvang rigs in the Gulf of Mexico, the fire ring mains run through hazardous areas, so both conductivity and fire endurance were specified, in keeping with U.S. Coast Guard regulations for the firewater piping systems. To meet these specifications, EDO is adding a proprietary fire-resistant additive to its standard resin and applying a conductive coating to the exterior of the pipe. Schmit explains that when both conductive and fire-resistant additives are mixed into resin, they tend to interact, causing the resin to lose physical and mechanical properties. “Our unique design kept both additives apart, thus avoiding the problem,” Schmit says. “In this case, we had a seawater-filled system, so our static electricity concern was external, not internal. In case of a fire, the exterior conductive coating simply burns away, leaving the fire-retardant structural cage.” The conductive coating is similar to the conductive resin that the company uses.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

.jpg;maxWidth=300;quality=90)