Proven Performance In A Chemical Line Installation

EDO Specialty Plastics (Baton Rouge, La., U.S.A.) filament winds composite pipe and fittings for offshore facilities platforms and rigs. Founded in 1973 as Specialty Plastics and acquired by EDO in 1998, the company manufactures industrial fiberglass piping systems for the chemical, petrochemical and pulp and

EDO Specialty Plastics (Baton Rouge, La., U.S.A.) filament winds composite pipe and fittings for offshore facilities platforms and rigs. Founded in 1973 as Specialty Plastics and acquired by EDO in 1998, the company manufactures industrial fiberglass piping systems for the chemical, petrochemical and pulp and paper industries in the Gulf Coast region of the U.S. While Mars was the first floating facility that it supplied, Kevin Schmit, manager of engineering, says the company has been doing other offshore systems since the 1970s. By 1991, the company’s trademarked FIBERBOND product line had been developed and customized for the offshore oil and gas market and the marine industry.

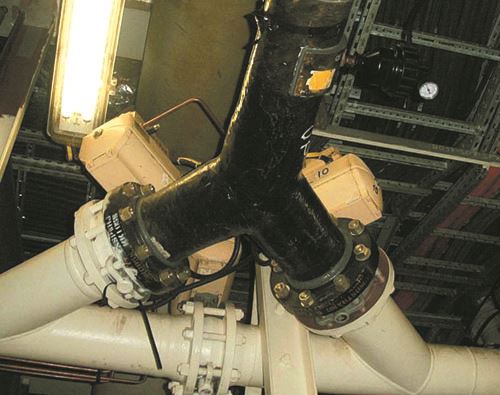

Schmit says applications include the following: wet and dry firewater systems — piping dedicated to fighting fire, either wet (continuously full of water) or dry (empty until needed); seawater systems (any piping that carries seawater, such as cooling water lines or water flood lines); ballast piping (water-filled piping installed below the deck that helps maintain rig stability); plus lines for freshwater and chemical service and for drainage. Pipe sizes are typically 2 inches/50 mm through 24 inches/610 mm, but the company has manufacturing capabilities for pipe up to 60 inches/1.5 m in diameter.

“The most common early application was column pipe,” Schmit says, describing this as a low-maintenance product as long as it is designed, manufactured and installed properly. “Once it gets through the commissioning process, any component has probably seen the most rigorous phase of its design life,” he points out. “It has sustained the abuse of installation and gone through the hydrotest, which pressurizes the entire system at 1.5 times its normal design rating to verify its integrity.”

Shell selected 10 inch/254 mm FIBERBOND for Mars’ fire ring main pipeline, the seawater-filled piping that circles the platform and is divided into sections via control valves. The ring main was installed at McDermott’s Louisiana facility. After the platform was in place offshore, Shell asked EDO to supply an additional 8 inch/203 mm chemical line, using the same support structure as the ring main. Since Mars was already in position, the new line had to be installed on a crowded platform that was positioned above the ocean surface. Sharing supports required the new pipe to span up to 20 feet/6.2m between supports, which imposed higher-than-normal stiffness requirements.

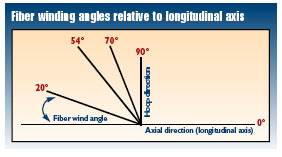

As Richard Lea, Specialty Plastics’ founder and now manager of special projects for EDO, explains, the classic 54° filament-winding angle is not necessarily the best fiber orientation for a long, unsupported span, which places more stress on the pipe in the axial direction. The span requirement mandated a stiffer bending modulus. Increasing the wall thickness of a normal 54° wind would have increased the bending strength, but would have exacted a penalty in more material and therefore greater weight. Using micro-mechanics and classical lamination theory, the company identified an improved winding pattern that minimized wall thickness while still allowing the 8 inch pipe to be installed adjacent to the 10 inch pipe, using the same supports. The result was a pipe design that called for multiple angles: ±20° and ±70°, instead of the traditional single 54° angle. Wall thickness of less than one-half inch (0.4375 inch/11.1 mm) was achieved using this fiber architecture.

A liner consisting of two layers of polyester surfacing veils from Precision Fabrics (Greensboro, N.C., U.S.A.) was placed on the mandrel, followed by two layers of 1.5 oz E-glass chopped-strand mat to act as a corrosion barrier between the liner and the filament-wound pipe structural cage. The liner and mat were both wet out by epoxy vinyl ester resin with fairly high elongation characteristics and high heat-distortion resistance (245°F/118°C). After compaction, the liner and corrosion-barrier layup was oven cured. Another layer of resin and mat was then applied as an interface between the corrosion barrier and the structural cage. Winding of E-glass roving then commenced at the specified angles. No special conductivity service was needed for the Mars application.

Schmit says he has lost count of the number of platforms that EDO has supplied since Mars. “We’re probably on over 50 platforms in the Gulf of Mexico alone,” he says, “Shell’s Ram-Powell and West Delta 143, Texaco’s Petronius, Chevron’s Genesis and Exxon Mobil’s Hoover- Diana, to name a few.” McDermott has installed EDO composite piping systems on Shell’s Ram-Powell, Ursa and Brutus, and Chevron’s Genesis. FIBERBOND piping also serves offshore in the Caribbean, the North Sea, west of Africa — on Exxon Mobil’s Zafiro floating production unit (FPU), located off the coast of Equatorial Guinea in Africa, for example — and along the Pacific Rim, including ballast lines in the concrete gravity substructure (CGS) of the Shell Philippines Exploration B.V. Malampaya in the Philippines. Projects in progress at this writing are the Brutus TLP for Shell, the Hibiscus platform for British Gas, and the Nansen and Boomvang spars for Kerr McGee.

Related Content

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreOptimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

Design Issues

Typical FRP pipe is reciprocally filament wound with a fiber angle of ±54.75° relative to the longitudinal (0°) axis. This architecture satisfies stress loads in both the circumferential (hoop) and longitudinal (axial) directions for most pipes and pressure vessels. It withstands the in-use pressure, ther

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)