Design Issues

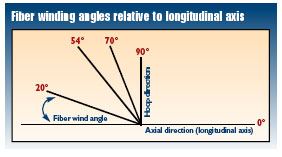

Typical FRP pipe is reciprocally filament wound with a fiber angle of ±54.75° relative to the longitudinal (0°) axis. This architecture satisfies stress loads in both the circumferential (hoop) and longitudinal (axial) directions for most pipes and pressure vessels. It withstands the in-use pressure, ther

Typical FRP pipe is reciprocally filament wound with a fiber angle of ±54.75° relative to the longitudinal (0°) axis. This architecture satisfies stress loads in both the circumferential (hoop) and longitudinal (axial) directions for most pipes and pressure vessels. It withstands the in-use pressure, thermal expansion and contraction, and the surge loads induced by thrust due to water pressure, as well as the normal bending and tensile loads that may occur during installation. All of these factors must be considered in the design of the overall piping system, which includes the pipe, fittings and supports such as the anchors, guides and hangars (typically steel) that hold the pipe in place. It is preferable to filament wind fittings, such as elbows, Ts, laterals, reducers, crosses and Ys, with the same materials used to construct the pipe itself. This ensures a high degree of stability and safety. Pipe manufacturers typically line pipes with the same resin as that used in the structural laminate of the pipe wall. A corrosion- resistant veil (a thin, nonwoven fibrous reinforcement) is often incorporated into the liner.

Fiberglass piping is usually joined by adhesive bonding or butt-welding. Adhesively bonded joints fall into two main types: straight-by-taper and taper-by-taper. Straight-by-taper means a slightly larger socket is integrally wound at one end of the pipe, and a mating “spigot” is shaved to a slightly smaller diameter to ensure a close fit. As the spigot is forced into the socket to a fixed stop point, all air is purged out of the joint and the resin adhesive ensures a good bond. For some larger diameter pipe, the taper-by-taper joint adhesively bonds mating male/female tapered ends, although some special tools can be required for tapering. Butt-welding or butt-and-strap methods use hand layup to join two pipe ends of the same diameter. The two ends are butted together and the joint is wrapped with resin-wet layers of chopped-strand mat and woven roving, the same materials that are used in the pipe itself. Both adhesive joining and buttwelding require trained personnel and proper surface preparation to achieve good results. A mechanical O-ring bell and spigot seal lock joint is a third option, sometimes employed for a long length of large-diameter pipe.

To join composite pipe to metallic pipe or equipment, a composite flange is either wound or bonded onto the pipe, then bolted to pumps, valves or other metal equipment on-site. Other, proprietary mechanical couplings are offered by manufacturers to mate composites with metallic fittings. But methods that require penetration of the composite pipe wall should be avoided, since breaking the fibers decreases the pipe’s performance properties.

In addition to its light weight and high strength-to-weight ratio, composite piping’s corrosion resistance is another big advantage. In contrast to steel pipe, which corrodes quickly when exposed to seawater, composites are virtually corrosion-free when made with chemical-resistant resins. For platform components such as column pipe (pipe that extends from the platform down below the water surface to supply seawater) and firewater systems, corrosion resistance means years of maintenance- free service. David H. DeMoss, systems design/application engineer with DSX Sepco Industries (New Orleans, La., U.S.A.), says, “We found that steel pipe was often severely corroded after just a couple of years’ service. We’ve installed over 10,000 composite column pipe applications, and several are more than 25 years old and still going strong.” According to DeMoss, DSX Sepco typically designs composite systems with a 40-year life for topside service. Column pipe applications last an average of 20 years, due to the stress on the system and the need to remove the pump every two years for service.

Fred Landry of J. Ray McDermott, a well-known offshore platform fabricator in Morgan City, La., says that, for fire pipe, composites are actually cheaper than the copper/nickel alloy that is typically used. Landry points out another advantage of composites — composite pipe can be fabricated in fewer pieces, with fewer connections, to fit unusually shaped and tight quarters, if necessary. Its lower modulus gives composite piping elasticity and flexibility in configurations that are not possible with rigid, higher-modulus steel. This feature can be a considerable asset for designers who are fitting miles of supply lines for multiple purposes into a limited space. Plus, bonded joints eliminate the need for steel welding, which is a potential fire source on platforms with flammable hydrocarbons.

It should be remembered, however, that composite pipes can be damaged by concentrated impact loading, which can happen if they are dropped or struck by heavy objects. For this reason, Landry typically installs composite pipe at the end of a job, to minimize the possibility of damage. “I constantly remind the customer that FRP is not steel and should not be handled as steel,” says Landry, adding that, because composite pipe flange connections have to be torqued to specific levels to avoid crushing, his people do not complete these installations. Instead, he has the pipe manufacturer’s personnel come to the yard to make the final connections and tie-ins.

The coefficient of thermal expansion (CTE) of fiberglass pipe is another issue, he says. When composite piping is suspended from steel hangers, the CTEs of the different materials must be factored in. The composite needs room to move, and a wear pad must be installed on the pipe’s outer surface to protect it from damage or crushing. The U.K.’s Health and Safety Executive (HSE) has reported at least one bonded composite pipe joint failure due to surge loading when the pipe filled with water. Therefore, the design of pipe supports as well as joints must also take surge loading into consideration. For example, T-joints can be strengthened by adding gussets.

Fire safety is a critical issue on offshore installations. Composite topside piping has proven its performance to regulators to the extent that it may carry water, in compliance with International Maritime Organization (IMO) Level 3 Fire Endurance standards, i.e., IMO Assembly Resolution A.753 (18) for water-filled plastic piping. The Level 3 resolution covers all polymeric materials, whether thermoset or thermoplastic, fiber-reinforced or un-reinforced. At this time, regulations do not allow the use of composite pipe for flammable liquids, such as hydrocarbons or diesel fuel, because the stringent Level 1 (rather than Level 3) standard is applied to this type of process piping. Knowledgeable industry insiders feel that IMO Level 1 compliance is currently beyond the practical economics of composite piping.

The offshore fire resistance of composites has been addressed and largely resolved by the use of phenolic resins, special fire-retardant additives and intumescent coatings (materials that swell and char when exposed to flame, protecting the underlying laminate). Phenolics, thermosetting resins based on phenol and formaldehyde chemistry, have high temperature and burn resistance and generate only small amounts of smoke and toxins during a fire. Additive materials such as antimony trioxide, bromine, chlorine, borate and phosphorus improve a resin’s fire resistance. Intumescents can successfully insulate the inner structural layers of a host product even when subjected to hydrocarbon and jet fire temperatures approaching 1830°F/1000°C. (Jet fire refers to the most severe fire scenario on a platform, the release of a flammable material under high pressure.)

Fiberglass piping is non-conductive (i.e., an insulator) and therefore does not provide a path to earth for static electricity. Conductivity is a complex issue that the industry has been hesitant to deal with, says Philip Medlicott of Trevor Jee Associates (Tunbridge Wells, Kent, U.K.), a composite consultant to the oil industry. Medlicott is responsible for drafting ISO 14692 (see "Regulations" below). “The proposed standard provides a practical, performance based approach for addressing static electricity issues in fiberglass piping applications,” Medlicott states, noting that it “is also applicable to non-piping applications.” He adds that IMO Resolution A.753 (18) has created the impression that static grounding is unique to composite piping systems, but it is not. “In fact, the issue is relevant whenever there are electrically isolated conductive components located in hazardous areas,” he says.

When the fluid inside a pipe has conductivity of more than 10,000 pico siemens per meter (pS/m) — as is the case for seawater and crude oil — pipe conductivity is generally not required. Even in this case, however, some debate exists about whether or not conductivity should be required in a hazardous area; for example, where a flammable atmosphere might be present or a pipe puncture could release flammable substances. The ISO 14692 standard recommends a risk assessment based on evaluation of other specific conditions. This is contrary to the prescriptive approach of IMO A.753 (18) typically specified, which recommends that “regardless of the fluid being conveyed, plastic pipes should be electrically conductive if the piping passes through a hazardous area.”

To make FRP pipe conductive, conductive carbon fiber can be added to its glass fiber reinforcements or carbon powder can be added to its resin systems. For example, Ameron International (Houston, Texas, U.S.A.) winds carbon fiber tow in with the fiberglass, spaced so that it forms a grid pattern. The company maintains that conductivity through the wall is ensured by the intersection of the carbon strands as one layer lies on top of the previous layer. The carbon fibers contact each other and provide through-the-wall conductivity as well as end-to-end conductivity. Since the carbon is stiffer and stronger than glass fiber, the hybrid design also improves the structural performance of pipe.

Related Content

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreComposites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

-Imping.Flame%20Fire%20Test.jpg;width=860)