Photo Credit: Getty Images

Windows, whether in homes or commercial buildings, are a notorious source of energy inefficiency, letting too much heat indoors in the summer, or too much heat outdoors in the winter. This inefficiency has been tolerated for centuries because of the benefits windows convey to humans: access to sunlight, a view of the world outside and a strong design aesthetic. In short, windows are here to stay.

Given the architectural permanence of windows, emphasis has been placed over the past several decades on making them more insulative and efficient. This has been done with a variety of materials and designs. Double-pane glass, for example, first developed in the early 1900s but not widely used until the 1980s, added an insulative layer of air (between the panes) to window systems. The application of aluminum and vinyl to window frames, the advent of UV-blocking films and the addition of a third pane also increased efficiency.

In the window manufacturing industry, one of the largest efforts to increase window efficiency has revolved around use of advanced materials to thermally segregate the exterior window frame structure from the interior window frame structure, thereby minimizing energy transfer through the window system.

Quietly and doggedly pursuing this challenge for the past couple of decades is an array of increasingly complex extruded or pultruded profiles designed to integrate fiber-reinforced composite gaskets into the space directly below the glass and between the structures comprising the exterior and interior frames. These “thermal breaks” are leading window systems into a new era in energy efficiency.

Measuring, regulating window efficiency

Windows provide myriad opportunities for heat loss or gain in a building or home. Thermal energy outside or inside the window can be readily transmitted through the window system in one of three ways, says Bill Blazek, market team manager at Technoform (Twinsburg, Ohio, U.S.), a manufacturer of thermal breaks. Convection, which is air circulation in the cavity, accounts for about 35% of the energy flow. Conduction, which is energy flow through solid materials, accounts for about 50% of transmission. Finally, radiation occurs from a warmer surface to a colder surface and accounts for about 15% of the energy flow. Because of this, the quality of window design and materials of construction have substantial impact on the overall energy efficiency of a window.

Over the last 20 years or so, as concerns about global climate change and energy efficiency have grown, government regulators have increasingly targeted improved window energy efficiency as a tool to help moderate energy consumption in homes, offices buildings and other structures. As a result, every new construction or renovation project undertaken provides an opportunity to incrementally increase window — and, by extension, building — energy efficiency.

Each country approaches this challenge differently. In the U.S., a window’s ability to resist thermal transfer is characterized by the U-factor, measured as Btu/hr-ft2°F. In Europe, efficiency is characterized by a similar term, the U-value, measured as W/m2K. In both regions, the smaller the U-factor/value, the better. The measure of a window’s performance under direct sunlight is characterized by the solar heat gain coefficient (SHGC), the values of which can range from 0.0-1.0; again, the lower the better.

There is a complex network of building codes that govern and regulate window energy efficiency around the world. Leading the way is the International Building Code (IBC) and the International Residential Code (IRC), which are administered by the International Code Council (ICC). However, each country and, in the U.S., each state, also develops its own codes that may depart from the ICC specifications. Further, although regulations vary from country to country, European efficiency standards, guided by aggressive energy conservation and greenhouse gas mitigation goals, are more strict than those in the U.S. For example, in Finland, one of the more strict EU countries, the U-value requirement is 1.0, which converts to a U-factor in the U.S. of 0.18.

In the U.S., conversely, energy efficiency standards are defined by region. There are four regions, each covering a west-to-east swath of the country: northern, north-central, south-central, southern. In the northern region, the U-factor standard is 0.27-0.30. In the north-central and south-central regions, it’s 0.30, and in the southern region it’s 0.40. These standards, using the European U-value, range from 1.5-2.3.

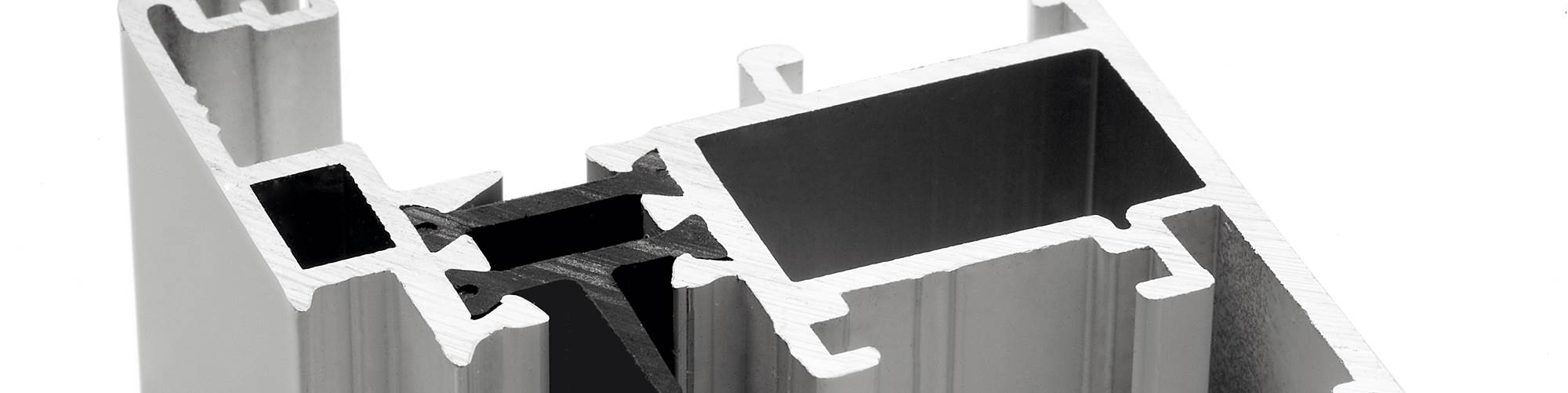

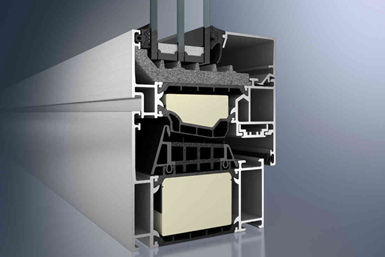

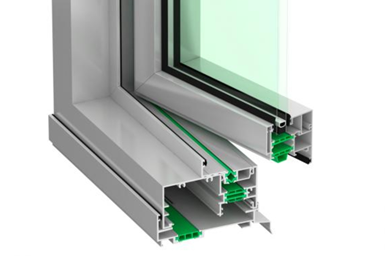

This cutaway of a Schüco aluminum window frame shows the series of polyamide/glass fiber (black) and foam (white) thermal breaks that segregate the exterior of the frame (left) from the interior of the frame (right), to minimize energy transfer and maximize efficiency. Note also that this is a three-pane window. Photo Credit: Schüco

A thermal break is born

David DeSutter, VP of engineering and project services at window and curtain wall manufacturer EFCO (Joplin, Mo., U.S.), says there is a global predilection for aluminum-framed windows, particularly in commercial construction. Aluminum is relatively inexpensive to acquire and to extrude, and because it is readily paintable, it can meet a variety of color requirements. Further, DeSutter says, the thickness of aluminum frames can be easily adjusted to meet a variety of architectural needs — for example, to emphasize or de-emphasize the frame, thereby emphasizing or de-emphasizing the glass in the window itself. One of the things aluminum also does particularly well is conduct energy. “Aluminum is one of the best thermal conductors on the planet,” he says. “It has a lot of great properties, but thermal efficiency is not one of them.”

As noted, multi-pane glass and other technologies do an effective job mitigating energy loss inside an aluminum-framed window, but there still exists a challenge to mitigate energy loss around the aluminum frame. One way to do that, says DeSutter, is to fully segregate the exterior and interior sections of the aluminum frame with the insertion of a highly insulative polymeric material to minimize energy transfer around it.

This insulative gap, or a thermal break, says DeSutter, is typically made with polyamide and is either extruded, with multi-directional glass fiber reinforcement, or (less commonly) pultruded, with continuous glass fiber reinforcement. Blazek, at Technoform, which extrudes thermal breaks for EFCO, says polyamide is frequently the material of choice for thermal breaks because its CTE is similar to aluminum’s, it has good thermal and structural characteristics, reliable quality, enables precision parts with tight tolerances and it’s readily recyclable. He adds that glass fiber loading in a thermal break typically ranges from 25-40%, depending on structural requirements.

In its most basic design, a thermal break comprises a tubular profile with a hollow center. EFCO’s first thermal breaks, developed a decade ago, were about 12 millimeters wide and 5 millimeters thick, but today, says DeSutter, thermal break width at EFCO can span more than 25 millimeters; Blazek says Technoform can produce thermal breaks that are even wider still. Much of this evolution in thermal break design at EFCO has been driven by increasingly stricter U.S. building codes. DeSutter notes that for many years, the U.S. U-factor standard was 0.45, but as it was gradually reduced to the 0.27-0.40 range in effect today, EFCO was compelled to adopt more complex thermal break designs. “I know it doesn’t seem like a big change going from 0.33 to 0.31 in window efficiency, but I can tell you it is a very big deal,” DeSutter says.

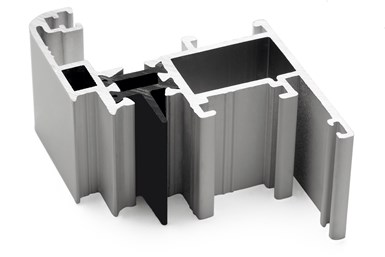

Technoform provides a variety of thermal break designs to window manufacturers. Shown here is a slice of one of the company’s extruded polyamide/glass fiber thermal breaks (black) between two aluminum frame structures. Photo Credit: Technoform

Driving thermal break design

The use of extrusion versus pultrusion to fabricate a thermal break comes down to the value and benefit of the type of fiber reinforcement — discontinuous (multi-directional) with extrusion and continuous with pultrusion. DeSutter says EFCO’s thermal breaks are extruded and feature discontinuous fiber-reinforced polyamide 66, which meets the strength and thermal performance requirements the company seeks.

At Technoform, which extrudes EFCO’s polyamide 66/glass thermal breaks, Blazek says thermal break design is influenced by a variety of factors: “The size and complexity of the thermal break is very system dependent and is chosen based on desired level of thermal performance, thermal transmittance — also known as the U-value — structural requirements, other system design characteristics such as window type, hardware, glass makeup, the function of the part within the system and overall system cost targets.”

Naturally, as thermal break design complexity increases, so does cost, says Blazek: “The associated costs are often offset with the value it brings to the system and long-term energy savings, health benefits to the building and its occupants. The design and tooling challenges are overcome through our global network and extensive resources to constantly innovate and develop the right solution to meet any challenge.” Blazek adds that for many projects in North America, value engineering (despite the emphasis on “value”) often leads to the acceptance of lower cost/lower performing systems. “The greatest hindrance to the adoption of advanced thermal break material is the focus of the North American market on short-term costs instead of the long-term value associated with building energy efficient, healthy structures,” Blazek says.

What might a more advanced thermal break look like? In Europe, more stringent thermal efficiency requirements have prompted development of highly complex, multi-chambered thermal breaks. For example, window manufacturers Schüco (Bielefeld, Germany) — for which Technoform also supplies thermal breaks — and Thermeco (Victoria, Australia) showcase fixed and opening window systems that feature multiple thermal breaks, with each break designed to fit into a specific space in the frame. Further, such breaks often feature multiple chambers that enhance insulation.

One question is if and how pultrusion might become an option for thermal break fabrication. Composites fabricator Exel Composites (Vantaa, Finland) specializes in the manufacture of composite parts and structures for a variety of end markets, including residential and commercial building and infrastructure applications. Gert De Roover, group segment owner building and infrastructure at Exel, says extrusion of polyamide/glass fiber profiles, with polyurethane foam sometimes added for additional insulation, is the standard material and process combination for window thermal break manufacturing. He acknowledges, however, that as window systems become more complex and as frames widen, demand for thermal breaks that also provide structural properties likely will increase.

European building codes dictate stringent standards for window energy efficiency, which is driving development and use of more complex thermal break designs, including pultruded structures. U.S. standards lag behind EU standards, but are likely to become more strict in the next several years. Shown here is a window from Australia-based Thermeco, with thermal breaks shown in green. Photo Credit: Thermeco

For example, says De Roover, Exel has developed a line of pultruded glass fiber/polyester door blades and lintels that provide insulative and structural properties. Such attributes could become appealing in window system — particularly given the wide use of aluminum frames. “There [in blades and lintels] you see the benefits in the thermal insulation, together with the structural integrity of the material,” he says. “Blades and lintels have a certain span and certain stiffness of importance, and pultrusion allows us to meet those requirements.”

Some manufacturers of custom window systems, especially for residential applications, are already turning to pultruded thermal breaks. For example, U.S.-based window manufacturer Arcadia Custom specifically calls out use of pultrusion in its thermal break systems. And polyurethane (PU) resin supplier Covestro (Pittsburgh, Pa., U.S.) is targeting its Baydur PU toward pultrusion of window thermal breaks specifically for the Chinese market.

Evolving thermal breaks into the future

Regardless of the process, Technoform’s Blazek says the U.S. construction industry should expect to see a trend toward increasing design complexity in thermal breaks in the next few years. “The building codes are progressing at a slow and steady pace allowing for incremental system development,” he says. “In the U.S., several areas of the country are leading the way such as California and New York. In California, Title 24 has been the catalyst to encourage innovation and improve system thermal performance. In New York, NYC Local Law 97 and WA State HB1257 will strongly push existing building retrofits to avoid fines for exceeding carbon, energy emission limits. This starts in 2024 with the worst buildings, expanding to cover significantly more by 2030.”

Further, he says, the 2020 National Energy Code for Canada for Buildings (NECB) is nearing publication and will include very aggressive U-factor changes. Similarly, the U.S. government is moving more aggressively to encourage the adoption of more energy-efficient systems with the Energy Act of 2020, which is included as part of the COVID-19 relief and appropriations package that passed the U.S. Congress in December 2020. Globally, says Blazek, the 2024 International Building Code (IBC), 2024 International Energy Conservation Code (IECC) and the ASHRAE 90.1 and 189.1/International Green Construction Code all have strong initiatives to advance codes for more energy-efficient systems. Blazek concludes: “I would expect this evolution in the U.S. to continue with slight market shifts toward long-term energy efficiency and healthy building practices, increased adoption and enforcement of codes requiring improved energy efficiency and performance.”

Related Content

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreEuropean boatbuilders lead quest to build recyclable composite boats

Marine industry constituents are looking to take composite use one step further with the production of tough and recyclable recreational boats. Some are using new infusible thermoplastic resins.

Read MoreMetal AM advances in composite tooling, Part 2

Toolmakers and molders continue to realize the benefits of additive versus conventional/subtractive manufacturing of molds and mold components.

Read MoreBio-based, fire-resistant composites become mainstream

Projects use Duplicor prepreg panels with highest Euroclass B fire performance without fire retardants for reduced weight, CO2 footprint in sustainable yet affordable roofs, high-rise façades and modular housing.

Read MoreRead Next

Innovative tooling, automation enable new line of composite window wells

Moldmaker and automation specialist Commercial Tool Group provided RockWell with custom compression molds and robotics to enable high-volume, low-cost production.

Read MoreFiberglass composites improve infrastructure efficiency and sustainability

Gert de Roover, building, construction and infrastructure manager at Exel Composites, explains why composite materials contribute to the drive for greener buildings.

Read MoreUshering in a new era for windows … and more

Superlative stiffness and thermal efficiency could make this highly glass-filled pultruded polyurethane insert a construction industry go-to material of choice.

Read More