Composites enable micro air vehicle

Real-time sensing capability makes slow-flight VTOL MAV a "man replacement."

Design Results:

- Lightweight composites minimize vehicle weight.

- Low-cost tools, economical material choices keep costs down, enabling designers to meet "consumable" design goal.

- Solid-state battery becomes the vehicle's structural member, further reducing weight by eliminating stiffening members.

Unmanned aerial vehicles (UAVs) are multiplying and evolving at an incredibly high rate. A noted aerospace research and consulting firm, The Teal Group (Fairfax, Va.), pegs 2008 worldwide expenditure for UAVs at $3.4 billion (USD) and says it's the most dynamic sector of the aerospace market. The explosive growth encompasses systems large and small, including "micro" air vehicle (MAV) concepts less than 1 ft/305 mm in length.

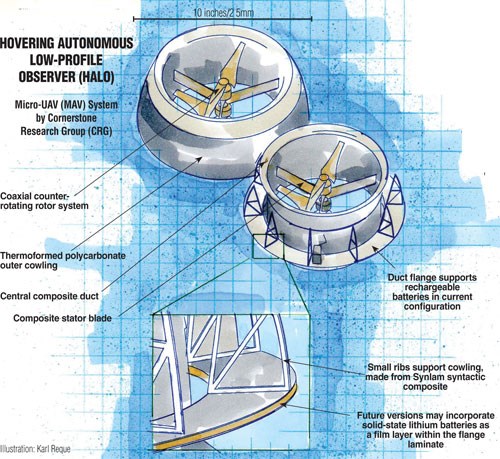

MAVs have generated interest in many sectors, both military and civilian, because of a shift in war fighting and policing strategy. Instead of putting soldiers or law enforcement personnel in harm's way, the new trend is to field an unmanned surveillance device, essentially a "man replacement" that can be considered a consumable, says Ernie Havens, chief engineer at Cornerstone Research Group (CRG, Dayton, Ohio). The company has developed a unique vertical takeoff and landing (VTOL) MAV system termed HALO, for Hovering Autonomous Low-profile Observer. HALO is designed to provide real-time sensing and surveillance in both outdoor and indoor environments and eventually could be deployed from an airplane in intelligent "swarms." Originally developed for the U.S. Air Force, CRG's MAV HALO concept is now available for commercial applications. "It's a new — and very affordable — concept that allows access to areas like urban conflicts or areas that are unsafe for people, such as search and rescue situations," says Havens.

Integrated design minimizes weight and cost

CRG's 10-inch/25-mm diameter HALO is a big departure from more typical winged unmanned vehicle designs. "The idea here was not to create a vehicle with wings that would circle over a target but rather something that could enter and exit buildings, avoid obstacles or quietly surveil an area or an enemy," says Chris Hemmelgarn, CRG's Aerosystems business area manager. That meant a slow-flight vehicle, with the ability to quietly hover, ascend and descend while recording and transmitting video or other data — something more akin to a helicopter. The company started with a "clean sheet" approach to meet its client's requirements, which, in addition to the capabilities previously mentioned, included minimal weight, long loiter (extended, uninterrupted flight time), adequate payload capacity (with the ability to switch out payloads) and, because it had to be expendable, low cost. Whether or not CRG would meet all of these priorities hinged on development of an efficient propulsion system, which presented a big hurdle, says Hemmelgarn. Further, the concept meant that slow-flight aerodynamic problems had to be solved to create sufficient lift and to maximize propulsive efficiency at low speeds.For the propulsion unit, Hemmelgarn's team devised a coaxial counter-rotating rotor system inside a cylindrical fan case or duct. A solid shaft that supports a two-bladed rotor would be enclosed by a second, hollow shaft that would support a similar two-bladed rotor above the first, rotating in the opposite direction. The coaxial shaft, in turn, would be supported by three solid arms or stators to center it within the circular duct. Small electric motors mounted on the coaxial shaft would power each rotor. The upper rotor would be equipped with a tiny swash plate, like that used in a full-scale helicopter, so that it could act as a cyclic and be feathered for directional control.

Power would have to be supplied by batteries, which would drive the small electric motors. The design team elected to distribute the batteries in the shape of a flat ring around the lower circumference of the duct, essentially forming a flange or shelf, to give the vehicle as low a center of gravity as possible for greatest stability. Payloads, including cameras or sensors, could be attached on top of the battery ring or flange — making sure that loads would be balanced to maintain the vehicle's stability, says Hemmelgarn. To protect the duct, batteries and payloads, the team envisioned an easily removable outer aerodynamic shell or cowl around the entire vehicle, supported by small, lightweight ribs attached to the battery ring.

"Aerodynamic analysis, rotor blade design, drive system selection, battery selection and the design of the main structural components were all performed simultaneously to achieve the project design goals," notes Hemmelgarn. "Obviously, composites were our first choices for the HALO's components to reduce overall system weight."

Composite materials make goals attainable

Lightweight yet affordable materials were the key to meeting the project's strict weight and payload goals. The central duct is a thin-walled cylinder, hand layed using an off-the-shelf plain-weave carbon/epoxy prepreg and unidirectional carbon/epoxy prepreg, cured at low temperature on a low-cost tool. Injection-molded composite material is used for the rotors; the coaxial shaft and bearings are metal; and the stator arms are also carbon/epoxy prepreg, adhesively bonded to the duct's inner surface.Batteries, the "power weight groups," tend to be heavy and can be deal killers in MAV design. To cut weight, Hemmelgarn says, it was important to make the battery do double duty as a structural member. CRG chose to place rechargeable lithium polymer batteries in a ring around the outside of the duct, basically resting on a flat flange laminated to the lower edge of the duct. By having the batteries, in effect, become the MAV's main structural member, no additional structural supports were needed. In addition, the current design gives the battery ring enough strength to support the required payload instruments, he adds.

For future iterations of the HALO vehicle, Hemmelgarn reports that a state-of-the-art, thin-film, rechargeable solid-state lithium battery layer may be employed as part of the stator and duct structure. The solid-state battery concept would be robust enough to be embedded within the composite laminate of the flange, he says. "Any shear loads transmitted from the duct could be safely transferred through the solid state battery via the composite facesheets without affecting battery performance," explains Hemmelgarn. "Configuring the battery this way would give 30 minutes greater endurance and a lighter overall vehicle weight."

The small ribs bonded to the battery ring (see drawing, top left) that support the outer cowling are made from CRG's trademarked Synlam high-performance syntactic composite material — a prefabricated sandwich sheet, featuring syntactic foam core faced with thin carbon/cyanate ester prepreg in a novel layup. While the rib material is as light as traditional foam-cored sandwich panels, Synlam offers a significantly higher specific stiffness than traditional cored sandwich constructions, says the company, and is reportedly much lighter than a monolithic composite. To make the fine ribs, the material is waterjet cut and adhesively bonded to the battery ring. Finally, the outer cowling is made by thermoforming thin polycarbonate sheets. The polycarbonate provides sufficient toughness to survive bumps and scrapes at relatively low cost and weight.

An autonomous control system is currently being optimized and for now, says Havens, the MAV HALO is only available for sale as a radio-controlled vehicle. With the autonomous flight control system in the works, however, and additional control software being developed in-house by CRG personnel, the vehicle will have obstacle avoidance capability. When that step is completed, the HALO will be able to navigate its surroundings using vision-based strategies — similar to the way in which an insect flies — with the help of global positioning satellite (GPS) navigation. That would allow HALO MAVs to be deployed in swarms to gather surveillance information or locate people or objects over large areas.

Customizable concept enables customer-adapted features

CRG can tailor the HALO platform, giving customers the flexibility to customize vehicles for specific applications and payload requirements. The company's self-healing shape memory polymers (SMPs) also could be used to fabricate HALO units so that any damage to the vehicle could be repaired (see "Learn More" for related articles on SMPs). Havens describes one potential scenario: HALO units could be placed atop urban streetlight poles equipped with charging stations. When activated, one unit could be instructed to follow a vehicle or suspect; when battery power runs low, it could signal a second HALO to take its place, landing on the vacated pole-mounted charger. With its small electric motors, the vehicle is "almost silent" when compared to other VTOL concepts, notes Havens, an additional advantage for urban surveillance. Other potential market areas include environmental surveying, homeland security and border patrols. The unit's small size makes it backpack portable."By fielding swarms of intelligent yet inexpensive automata, this type of MAV technology has the potential to be a real step change in the modern battlefield," concludes Hemmelgarn. "Innovative composite materials and designs are part of that change."

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read More3D-woven composites find success in aerospace, space

CAMX 2024: Bally Ribbon Mills experts are displaying the company’s various joints, thermal protection system (TPS) technologies and other 3D woven composites for mission-critical applications.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreBraskem demonstrates PP solutions using Weav3D composite lattice technology

Partnership combines Braskem’s polypropylene sheets with Weav3D Rebar for Plastics technology to address new structural, automotive applications requiring high-strength, lightweight material solutions.

Read MoreRead Next

The changing shape of future aircraft

"Morphing" is no longer just for the birds.

Read MoreEMCs provide tougher alternative to shape-memory alloys and plastics

Composites Technology Development Inc. (CTD, Lafayette, Colo., U.S.A.) has developed TEMBO Shape Memory Polymers, elastic memory composites (EMCs) that are less dense and about one-fifth the weight of shape-memory metal alloys but deliver greater strength than other shape-memory plastics. "Most people think of

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More