Composites the right choice for subsea ocean observatory

Pultruded structure provides durable platform for Deep-ocean Environmental Long-term Observatory System (DELOS) project’s groundbreaking marine study.

Engineering challenge:

Design a strong and durable framework to support scientific instruments at the sea floor for more than 20 years.

Design solution:

Strong and corrosion-resistant pultruded glass/vinyl ester profiles are fitted together in a complex triangular structure that optimizes placement of critical scientific monitoring modules.

Increased demand for petroleum coupled with improved technology is prompting oil companies to tap reserves in progressively deeper offshore fields. Yet very little is known about these deep-ocean environments — a situation that oil giant BP (London, U.K.) wants to rectify. The company, in collaboration with a number of partners, has developed the world’s first system to monitor deepsea marine life for long periods, says Jim Clarke, BP’s project manager of local environmental impact. Although the company’s deepwater assets are increasing, there is limited understanding of oil production’s impact beyond the Continental Shelf, says Clarke: “We hope the DELOS project will go some way to redress that.”

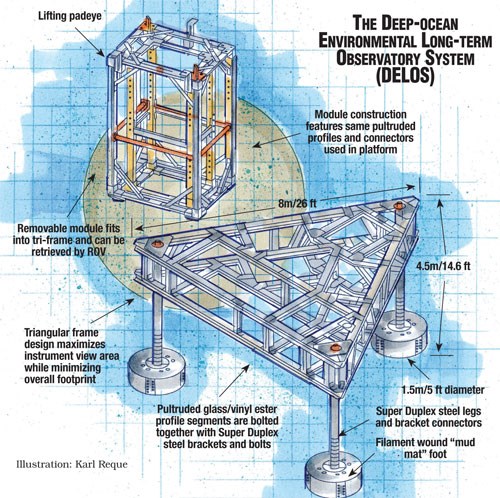

DELOS, which stands for Deep-ocean Environmental Long-term Observatory System, comprises two monitoring platforms made with pultruded composites. The platforms will be deployed in 1,400m/4,550 ft of water near West Africa. One will be sited within 50m/162 ft of a wellhead while the other will be located 8km/5 miles away from any wellhead to act as a control. The composite platforms will support several self-contained scientific mo-dules that will be retrieved and replaced periodically by remotely operated vehicles (ROVs). Organizations involved with BP in the DELOS effort include Oceanlab (Aberdeen, Scotland), the National Oceanographic Centre in Southampton (Southampton, U.K.), the University of Glasgow (Glasgow, Scotland), the Monterey Bay Aquarium Research Institute (Monterey, Calif.), Texas A&M University (College Station, Texas) and the Angolan National Institute of Fisheries Research. 2H Offshore Engineering Ltd. (Woking, Surrey, U.K.) was responsible for the system design, and Exel Composites U.K. (Runcorn, Cheshire, U.K., formerly Fibreforce Composites Ltd.), fabricated the composite structure.

Triangular logic

“The design was a collaborative effort,” reports Dr. John Hartley, technical director of Exel Composites U.K. The design group envisioned a robust, maintenance-free frame with adjustable legs to support the monitoring equipment above the sea floor and minimize impact on the seabed. Elevating the monitoring devices also would allow observation of the sea floor below as well as the water column above the station. The frame would have to maintain dimensional stability for more than 20 years at low temperatures and at great depth, where hydrostatic pressure is greater than 2,000 psi/173.9 bar. The frame materials would have to be not only corrosion resistant but inert as well, so as not to affect the biological processes of flora and fauna on the sea floor. Structural composite materials appeared to be the best solution for the project because they met all of the functional requirements. “Composites allowed the team to tailor the engineering to meet the objectives of the scientific research,” notes Hartley. The design that emerged was a triangular framework, or tri-frame, of interconnected, pultruded glass/vinyl ester profiles, 8m/26 ft on each side and 4.5m/14.6 ft tall, arranged to support four separate equipment modules — also constructed of bolted glass/vinyl ester profiles (see below) — with connectors and support legs made with Super Duplex steel. (Super Duplex is a 25 percent chromium stainless steel alloy designed for optimum corrosion resistance at low temperatures and often specified for subsea components.) The frame’s removable steel legs would be supported on round, filament-wound, glass/vinyl ester “mud mat” feet, each 1.5m/4.9 ft in diameter.

The platform’s triangular shape was dictated by the need for the DELOS instrumentation to be in contact with as much of the undisturbed deep ocean water as possible, says oceanographer Dr. Phil Bagley of Oceanlab, one of the team’s principal designers “It was also important for the DELOS instruments to be looking away from the DELOS,” he explains, “looking over the side and away from the framework, at the area most representative of the natural environment.” The triangular design accomplished this goal, and enabled the spacing between the instruments to be maximized, yet minimized the platform’s footprint to a degree not possible with a square structure, says Bagley.

During the environmental aging tests, finite element analysis (FEA) modeling was done on the proposed triangular frame, using ANSYS simulation software from ANSYS Inc. (Canonsburg, Pa.). Five load cases were simulated: 1) the platform in place (on the sea floor), using end of life properties, no ballast; 2) in place, using new material properties, with ballast; 3) in-air lift (simulating transport and loading), using as-new material properties, with ballast and rubber load; 4) an ROV impact case, using end-of-life material properties and finally, 5) loads on the smaller module frames, in place and during ROV lift, including the weight of the instruments and monitors. According to Hartley, the analysis assumed a load factor of 2.0 for the dead weight of the modules on the main tri-frame, and a factor of 1.4 was used for all other loads. A material factor of 3.0 was assumed, together with a dynamic analysis factor of 2.0 for the “padeyes” or module lift points (see drawing, top right) at the corners of the modules’ outer frames. Results of the FEA indicated where stresses would be highest, and helped the designers determine the number of profiles needed, their arrangement and bond area/connecting bracket thickness, says Hartley.

Prior to actual manufacture, prototypes of the heavy-duty, I-beam-shaped pultruded profiles were produced using a combination of glass roving (4800 tex) and continuous filament mat (450 gsm weight) wet out with vinyl ester resin, from proprietary suppliers. Typical part thickness was 10 mm/0.4 inch, reports Hartley, and all comply with the most stringent requirements of E23/EN13706-1:2002, a European Standards guideline entitled, “Reinforced Plastics Composites, Specifications for Pultruded Profiles.”

These initial articles were subjected to a variety of tests, including plate bonding and adhesive bondline thickness tests, because all joints were designed not only to be bolted together with Super Duplex connection plates and brackets, but also adhesively bonded as well, explains Hartley, using 3M (St. Paul, Minn.) Scotchweld 9323 corrosion-resistant epoxy adhesive. “It was a ‘belt and braces’ decision to prevent any connection failures,” he explains. “The steel connectors were a necessity — in some areas, for instance, where the legs are connected to the tri-frame, the large steel plates are 25 mm/1 inch thick, so it was not practical to make them in composite.” Other testing included profile bend tests, with and without bonded plates, and peel tests on the applied rubber blocks.

Ready to deploy

With the material specifications in place, the team employed SolidWorks from Dassault Systèmes (Paris, France), a three-dimensional design software program, to “virtually build” the entire platform and modules. Given the complexity of the numerous profiles and the variety of joints created by the triangular shape of the platform — some joints are straight (90°), some are angled — SolidWorks enabled designers to identify misalignments and mismatches in the design shop drawings before any parts were produced, says Hartley. With all of the complex components in place, the design information was ready for transfer to the production floor.All profile components were laser-leveled and assembled in the Exel facility, held together with temporary bolts, to ensure correct fit and design compliance. The precision-machined Super Duplex steel plates were then fixed in the proper locations and bolted. Modules were similarly bolted together and then fitted into their correct locations within the tri-frame. Assured the system met the specs, Exel then shipped the platforms and the modules to Oceanlabs. There, explains Bagley, they were reassembled with the legs and mud mat feet, and load tested by suspending weights on the legs while the entire platform was held with a large crane. The tests were sufficient to validate the design and work is currently ongoing to fit the modules with the oceanographic equipment.

As CT went to press in mid-November, the platforms were on their way to West Africa for deployment and initial data should be available within the next several months. Concludes Hartley, “To be quite honest, there were very few problems or issues with the project — with the design completed with CAD software and the components ‘virtually’ fitted together using SolidWorks before we manufactured any parts, everything went together very well.” Adds Bagley, “It was a collaborative effort that successfully identified the right materials for a very demanding application.”

Related Content

VIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreCompPair adds swift prepreg line to HealTech Standard product family

The HealTech Standard product family from CompPair has been expanded with the addition of CS02, a swift prepreg line.

Read MoreGKN Aerospace, Joby Aviation sign aerostructures agreement

GKN Aerospace will manufacture thermoplastic composite flight control surfaces for Joby’s all-electric, four-passenger, composites-intensive ride-sharing aircraft.

Read MoreRead Next

Composite tidal turbine to harness ocean energy

Glass, carbon composites are the materials of choice for system that harvests energy from tidal currents.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)